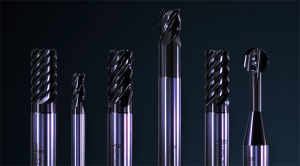

Solid Carbide Milling Cutter

Due to their geometry and good chip breaking, the milling tools are suitable for machining numerous other materials. Due to the precise combination of the substrate, the macro and micro geometry as well as the IG3 coating, the milling system exhibits high performance and long tool life. The coating in particular offers high temperature resistance for machining steels alloyed with chromium, nickel and molybdenum.