Automating High-Mix, Low-Volume Machine Tending

Automating High-Mix, Low-Volume Machine Tending

Finger grippers paired with a collaborative robot help minimize repetitive and monotonous tasks.

Founded in 2013 and based in Kecskemét, Hungary, family-owned BS CNC Workshop Kft produces precision metal components in its 900-sq.-m (9,688 sq. ft.) high-mix, low-volume production facility. The manufacturer operates three CNC lathes, four CNC milling machines and a conventional slab grinder. The company has grown steadily to become a supplier to several large multinational companies.

In 2020, BS CNC upgraded its quality assurance department by installing a measuring room that adheres to current standards. The temperature-controlled environment houses a coordinate measuring machine, a linear height gauge, a surface roughness gauge and an optical measuring machine.

BS CNC reports that it employs highly experienced personnel who specialize in CNC machining, locksmithing, programming and quality assurance. Machine tending is a time-consuming task for those valued employees, however, and the repetitive and monotonous nature of the task makes it difficult to hire and keep skilled operators.

Barabás Sándor, managing director and owner of BS CNC, said, "We knew that robotic automation could solve our challenges, but we were unsure if it was feasible to invest in automation due to the nature of our production."

BS CNC turned to Wamatec Hungary Kft, a system integrator that works closely with OnRobot to automate CNC machine tending. OnRobot provides tools and software for collaborative robot applications. (OnRobot Americas is in Irving, Texas.) Key to the solution was OnRobot's broad portfolio of flexible and intelligent electric grippers that can easily adapt to handle a range of different parts.

"After a proof of concept, we realized automating our high-mix, low-volume production was not a problem and that it would make financial sense," Sándor said.

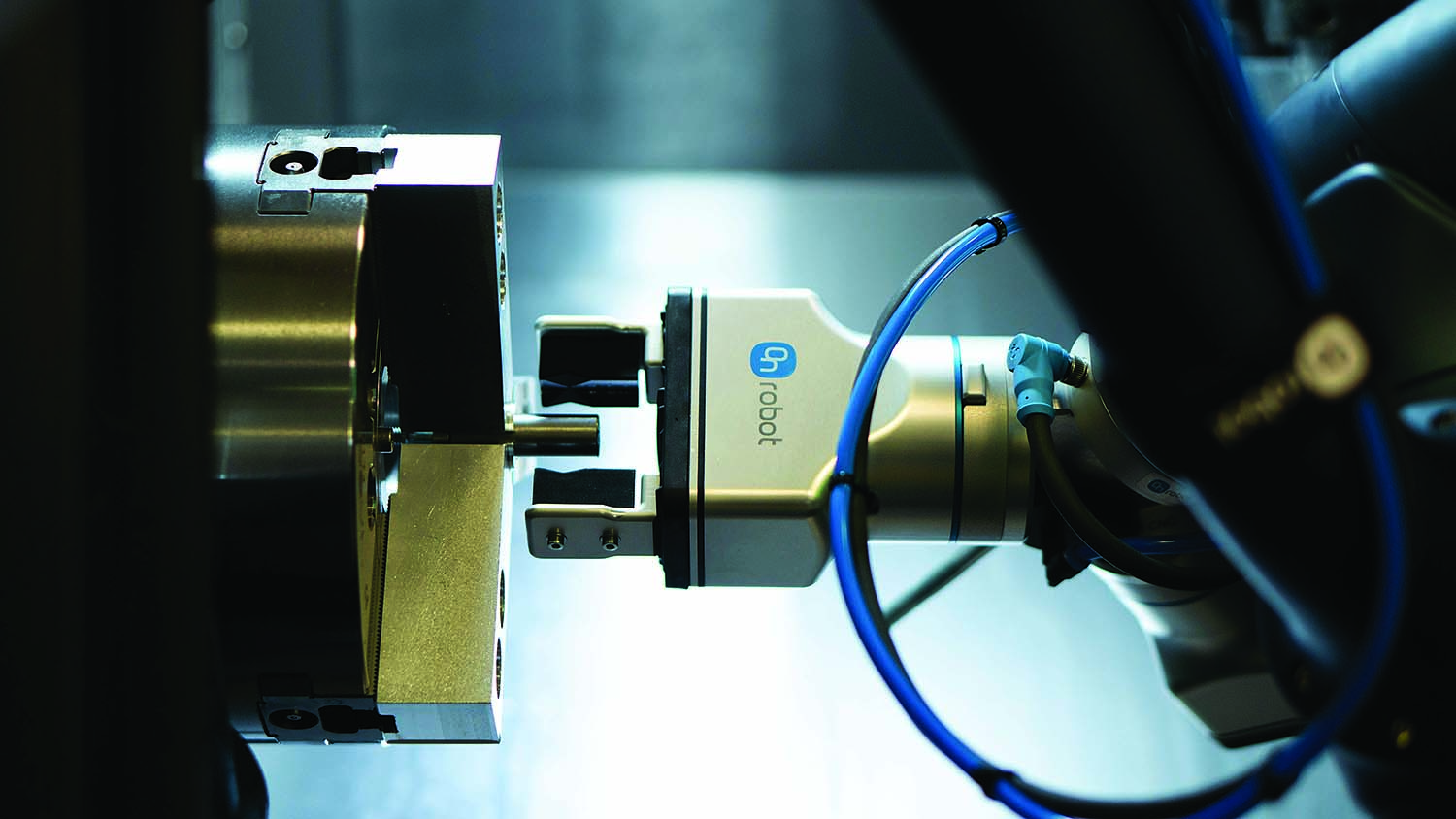

BS CNC selected two OnRobot 2FG7 electric finger grippers with the Dual Quick Changer paired with a collaborative robot from Doosan Robotics Inc. OnRobot's seamless integration with the Doosan cobot allowed the team to quickly get the system up and running using the familiar Doosan robot teach pendant interface

The compact OnRobot 2FG7 electric finger gripper offers flexible gripping for a wide range of part sizes and shapes. Image courtesy of OnRobot Americas">

The compact OnRobot 2FG7 electric finger gripper offers flexible gripping for a wide range of part sizes and shapes. Image courtesy of OnRobot Americas">Unlike custom grippers, the 2FG7 parallel finger gripper is reportedly easy to set up and run, handling the variety of parts needed and requiring no additional engineering or maintenance that would otherwise drive up costs. The gripper is well-suited for machine tending tasks because of its compact design and reliability in challenging manufacturing conditions where equipment is exposed to splashing water, oil and coolant. BS CNC boosted productivity by mounting two grippers in the Dual Quick Changer, allowing the robot to load and unload parts in one pass.

Before automating, the company typically produced 128 parts per shift. That increased to 155 parts per shift, for a 21% productivity improvement, Sándor said. "With the new solution, we have assured our CNC machines are always operational, enabling us to enhance our production hours by four."

Like many relatively small companies, BS CNC is able to realize the advantages of robotic automation that was previously only affordable for much larger manufacturers. The flexible, affordable OnRobot tools and Doosan collaborative robot have improved BS CNC's competitiveness, according to the parts manufacturer.

The company can now run its machine tending processes at full capacity for increased productivity, while freeing employees to do more valuable and interesting tasks. This also makes it easier to retain skilled employees. In addition, the flexible automation solution helps the company quickly respond to production changes without compromising on quality.

"Automating our CNC machine tending resulted in a 50% decrease of downtime," Sándor added.