Carbide control from chaos

Carbide control from chaos

Look Ahead: Researchers discover a new class of carbides that may be among the hardest materials with the highest melting points.n

Every week in the television series "Mission: Impossible" in the 1960s and 1970s, a team of five operatives assembled to combat the toughest problems of the world. Each operative brought unique elements to the team. In similar fashion, researchers from Duke University and the University of California, San Diego have collaborated to discover a class of carbides by combining carbon with a team of five—in this case, five cheap metallic elements. According to the researchers, the new carbides may be among the hardest materials and may have the highest melting points.

Traditionally, a carbide pairs carbon with another element. Because of their hardness and resistance to melting, the compounds created by pairing carbon with titanium or tungsten have many practical applications, such as surface coatings for cutting tools and parts of space vehicles. Some complex carbides also exist that combine carbon with three or more elements, but these often have been restricted to laboratories. Finding stable combinations has been challenging.

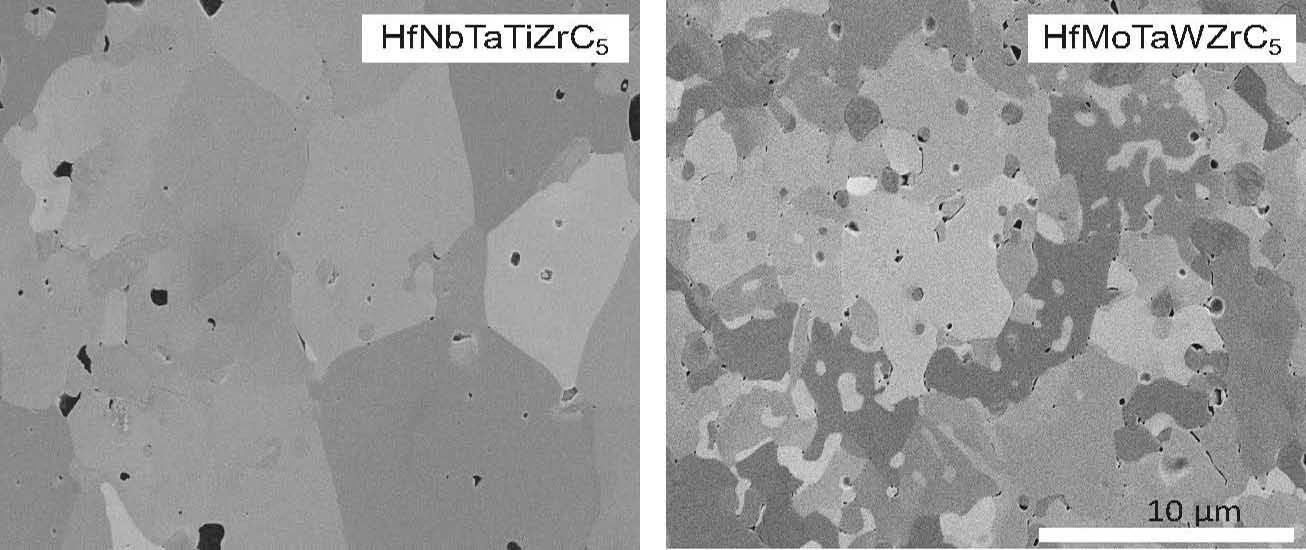

A microscopic look at the structures formed in two of the new carbides. The material on the left forms large blocks of similar structures, making it unstable, whereas the material on the right forms a broad range of structures, giving stability. Image courtesy of K. Vecchio

The new carbides, which combine nonmetallic carbon with five metallic elements, develop stability from their chaotic structure rather than from order. Duke's researchers provided the computational work that anticipated the carbides. Stefano Curtarolo, professor of mechanical engineering and materials science at Duke, said the carbides are harder and lighter than earlier ones and have higher melting points. The new carbides also were created from relatively inexpensive mixtures.

"Their attributes should appeal to a wide range of industries," he said.

Instead of focusing on traditional structures and bonds, the Duke and UCSD teams looked to disorder to provide stability and hardness. That approach led the researchers to combine the carbon with five metallic elements out of 91 available. The Duke team first narrowed the field to eight, considering which elements best formed carbide compounds with the desired features. Researchers modeled interactions among the eight to come up with a set of nine combinations—five elements were in each combination—to test further.

At this point, the UCSD team, headed by Ken Vecchio, professor of nano-engineering, attempted to synthesize the compounds. Because the materials behave differently, the team first had to determine how to combine them. Ultimately, the researchers used finely powdered forms of the elements, pressed them together at high temperatures and ran 2,000 amps through them.

"Of the nine combinations, the three we predicted most likely to work were in fact successful, as were three others," Vecchio said.

The standout, called Mo-NbTaVWC5, combined molybdenum, niobium, tantalum, vanadium and tungsten.

The teams will conduct further research to better determine the properties of the new carbide materials. That understanding will then lead to shaping their actual industrial applications.

For more information about Duke University's mechanical engineering and materials science department, call 919-660-5310 or visit www.mems.duke.edu. For more information about the University of California, San Diego's nano-engineering department, call 858-822-3071 or visit www.nanoengineering.ucsd.edu.