The essentials of manufacturing microtools

The essentials of manufacturing microtools

Manufacturing microscale endmills and drills requires ultraprecise machinery and specialty grinding wheels—never mind extreme skill, the right carbide grade and abundant patience. Thankfully, a number of toolmakers have become proficient at this microscopic task, leaving shops to worry about just one thing: making parts.

Cutting tiny parts and part features with an endmill smaller than a human hair ranks high on any shop's "let's avoid that" list. The feed rates are glacial, and the available spindle speed is usually far from adequate. Often the only way to know the tool has broken is with a microscope.

Now imagine making the cutting tool itself. Manufacturing microscale endmills and drills requires ultraprecise machinery and specialty grinding wheels—never mind extreme skill, the right carbide grade and abundant patience. Thankfully, a number of toolmakers have become proficient at this microscopic task, leaving shops to worry about just one thing: making parts.

Kyocera Precision Tools Inc. is a Costa Mesa, Calif., toolmaker that produces endmills down to 0.004" (0.1mm), reamers to 0.008" (0.2mm) and drills to 0.0015" (0.04mm), with geometries virtually indistinguishable from their larger counterparts. Micro industrial product and sales manager Joe Negron said many of these tools are applied in the medical and semiconductor industries. One of the keys to success in this micro realm is reducing runout—when the tool is manufactured and afterwards during use.

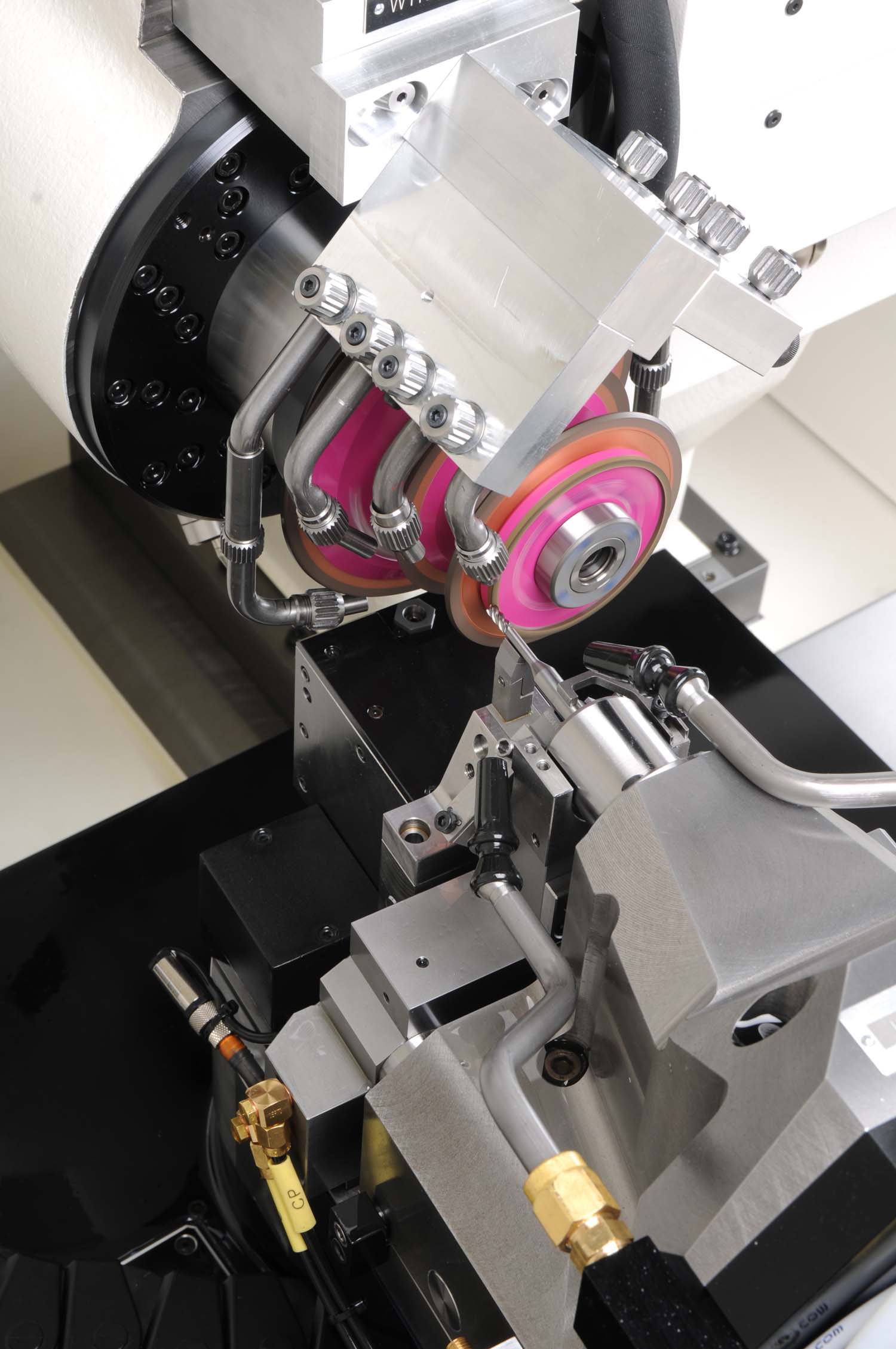

Microscale tool grinding requires extreme patience, attention to detail and a high level of skill. Image courtesy of Mikron Corp. Monroe.

"This is where you separate the men from the boys in terms of manufacturing technology," Negron said. "If you are unable to tightly control runout during machining, the tool will fail right out of the box. And without proper blank preparation when grinding—which means starting with a perfectly round, straight piece of carbide—manufacturing yields fall dramatically, which, in turn, drives up costs and makes tool longevity questionable. Compared to larger tools, where 0.0005" runout isn't going to hurt, you have to control it within millionths for microtools."

The communications coordinator at Rollomatic Inc., Mundelein, Ill., Bjorn Schwarzenbach, agreed that minimizing runout and blank preparation are critical to microtool grinding. He added that controlling deflection is also important.

"When you consider that you're usually starting with a 3mm-dia., or 1⁄8", blank, a relatively large amount of material is removed compared to the finished tool diameter. Therefore, deflection of the wheel and the tool can be pretty severe if left unmanaged," Schwarzenbach said. "In Rollomatic's case, we manage wheel stability with our PerfectArbor system, which compresses the arbor as a means of centering it on the wheel and provides a very rigid connection. For the tool, there's the Nanoset steady rest and U-block workholding system, which work together with the wheel arbor to minimize deflection."

Dress for Success

Schwarzenbach also said accurate wheel dressing via the CNC is necessary to achieve the extreme precision required on microscale tools, where diametral tolerances of 0.000039" (0.001mm) are common.

Markus Stolmar, vice president of sales at United Grinding North America Inc.'s Tool Div., Fredericksburg, Va., concurred. "With small workpieces, you need a very rigid, thermally stable machine. You must control cutting fluid temperatures and other process variables as closely as possible."

The PerfectArbor system compresses the arbor as a means of centering it on the wheel and provides a very rigid connection. Image courtesy of Rollomatic.

The irony of microtool grinding, Stolmar said, is that small tools take as long to grind as large ones. "You have to go very easy, otherwise you push the little workpiece away. This increases cycle time. The smaller the piece gets, the more complicated life becomes. Any sort of problem with the grinding wheel or tool runout is magnified exponentially."

This is where the operator comes in. A primary contributor to successful microscale tool grinding is having highly skilled operators, according to Stolmar. "Not a lot of people can do it. It takes a good deal of time to gain the necessary experience. You have to work very meticulously in setting up the machine and the grinding wheels and understanding the process. A good machine is important, but much of it simply comes down to the operator."

High-quality carbide is important too. That's why Swiss toolmaker Mikron Tool (represented in the U.S. by Mikron Corp., Monroe, Conn.) has "only a few carbide suppliers" with whom it maintains close relationships, said Project Leader Markus Schnyder. "For tools smaller than 1mm, the size and consistency of the carbide grains, as well as the cobalt binder, are critical to tool quality. When you get into the nano range, a boundary we define as 0.3mm and smaller, it becomes even more so."

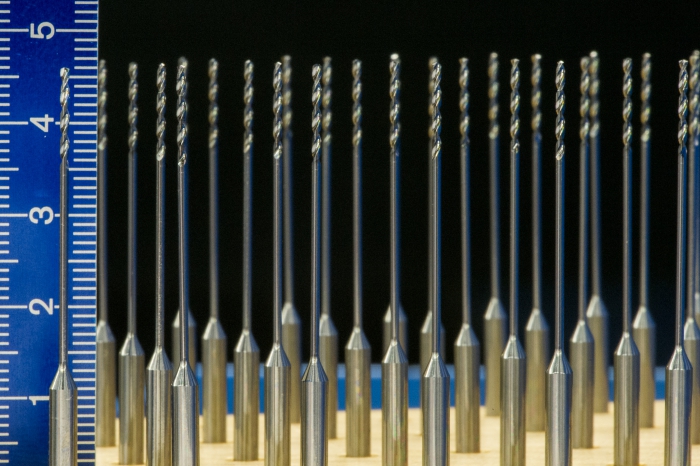

Thanks to advanced grinding technology, tools that would once have been considered rare are now commonplace. Image courtesy of Mikron Corp. Monroe.

Schnyder said internal stresses in poor-quality carbide blanks are often released during grinding, allowing the finished tool straightness to "relax" by 10 percent or more overnight. This scenario may also occur when improper grinding techniques are used, such as feeding the wheel too heavily in an attempt to remove large amounts of material quickly.

Pointed Recommendations

Cornelius Blumer, Mikron Tool production manager, summarized the six key points to successful microtool grinding, which he said is "like surgery":

- The machine tool must be highly accurate, with a comfortable working size not far from the operator and ergonomic qualities suitable for easy machine operation.

- Select top-quality, submicron-grain carbide blanks from a trusted and traceable source.

- A superfine grit wheel is necessary, one made with a precise shape that's properly mounted, dressed and balanced.

- Ultrathin coatings—0.5μm (0.00002") thick—should be applied after grinding to preserve edge quality and enhance chip flow.

- The correct digital optical inspection equipment, which, in Mikron's case, magnifies tool geometry 2,500×, is needed to monitor the grinding process.

- A highly trained and skilled worker, one who is "calm, cool and mature," is needed.