Form of solid carbide harder than diamond

Form of solid carbide harder than diamond

Researchers at North Carolina State University reported the discovery of a distinct form of solid carbon they estimate is about 10 percent harder than diamond and could play an important role in machining. They also claim to have developed a relatively inexpensive technique for producing the substance, called Q-carbon, at room temperature and ambient atmospheric pressure.

Researchers at North Carolina State University reported the discovery of a distinct form of solid carbon they estimate is about 10 percent harder than diamond and could play an important role in machining. They also claim to have developed a relatively inexpensive technique for producing the substance, called Q-carbon, at room temperature and ambient atmospheric pressure.

Besides being superhard, Q-carbon is ferromagnetic, unlike other solid forms of carbon, and glows when exposed to even low levels of energy, according to the scientists.

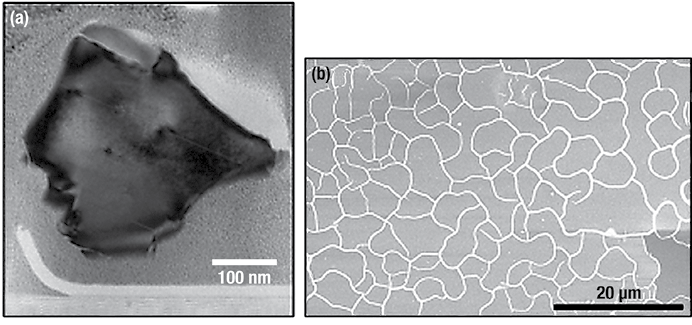

The researchers believe Q-carbon may exist in the cores of some planets. To produce it artificially, they coat a substrate with amorphous carbon, which lacks a well-defined crystalline structure. A laser pulse lasting about 200 nanoseconds hits the carbon, during which time the material's temperature reaches 4,000° K. The heated spot then rapidly cools via quenching to become a film of Q-carbon. At present, the researchers can make films from 20nm to 500nm thick.

Figure 1. (a) Q-carbon is a third phase of carbon alongside graphite and diamond; (b) The Q-carbon layer breaks into a cellular (filamentary) structure upon quenching. Images courtesy North Carolina State University.

Cutting tools could benefit from the material's hardness and its amorphous structure, which is not prone to cracking, according to Jay Narayan, the lead researcher. "I'm expecting that if you put a [Q-carbon] coating on top of diamond or cubic boron nitride cutting tools, the tools will last longer," Narayan said, adding that a coating thickness of a couple of microns should be sufficient.

For industrial applications, Narayan and his team must scale up Q-carbon processing. "When you have hundreds of tools, you'll need to coat them all in a limited amount of time," he noted. He added that scaling up the processing of Q-carbon might make it practical to make tools out of Q-carbon rather than just coating them with the material.

Another challenge is coating uneven surfaces. Right now, surface features such as steps that have areas perpendicular to each other, could present problems for the coating process.

But as for Q-carbon downsides, "I can't think of any," Narayan said. "I feel it's the holy grail."

For more information about North Carolina State University, visit www.mse.ncsu.edu or call (919) 515-2377.