Let’s chat

Let’s chat

Are machine shops ready to use MTConnect, an open and royalty free standard intended to foster greater interoperability between manufacturing devices and software applications?

Serious trouble can often be avoided with open communication. Consider the Cuban missile crisis, when the Soviet Union decided Cuban cuisine might taste better than borscht and black bread. Adlai Stevenson II, as the U.S. ambassador to the United Nations, worked with the U.N. to talk some sense into those belligerent Russians. And if Paul Revere hadn't told the colonists the British were coming, Americans might be driving on the wrong side of the road today.

Courtesy of DMG / Mori Seiki USA

Using Mori-WebMonitor, users can log in to access machine information remotely from any Internet-connected device and see an up-to-date status of their machine operations. The system uses an MTConnect adapter.

While war may not be ready to break out on your shop floor, that doesn't mean there aren't communication problems. Part manufacturing can often be like watching football on a foggy day: You don't know who fumbled the ball on the 5-yard line until the quarter's over.

MTConnect, which is an open, royalty-free standard intended to foster greater interoperability between manufacturing devices and software applications, attempts to lift that fog and clear the air.

Dave Edstrom, president and chairman of the board at the MTConnect Institute, McLean, Va., said, "Our vision is to provide an easy way for people to get information out of their equipment at a greatly reduced cost."

Another Pretty Face?

At a 2006 meeting of AMT—The Association For Manufacturing Technology, Edstrom made a bold statement: The industry was 21 years behind the curve in terms of communication. "Everyone was talking smart machines this and smart machines that. So I told them, 'Why don't you guys just get the damn things [manufacturing equipment] to speak the same language!' There was no reason to reinvent the wheel."

Edstrom explained that many new machine tools already had Ethernet on board or available as an option. HTTP and XML were well-established protocols by that time on the Web. Working with Dr. David Patterson of University of California-Berkeley, they convinced AMT that these communication standards had already worked for the computer industry for more than 2 decades—why not apply them to machine tools as well? Apparently, their speeches were convincing because AMT provided $1 million to develop MTConnect.

Oh, great, you're thinking, one more CNC interface to contend with, along with more programming, more complexity and more variables, while all you want to do is ship parts. Not so fast. Edstrom said: "MTConnect is not an interface, nor is it a programming language. It is a simple, royalty-free, open-source standard built upon proven protocols. Similar to browsing on the Internet, MTConnect lets you type in the name of a machine tool and receive back simple verbs, such as probe, current, sample and asset. You say 'send me data on what you're doing,' and the control returns that data to a database, spreadsheet or software program."

But hold on: Industrial control giant FANUC offers its Focas 2 interface, which understands more dialects than the linguistics department at MIT. Siemens has Profinet, Mitsubishi has EZ-Socket, and Mazak has Fusion. All of them are feature-rich and cost less than a weekend with the kids at a theme park. Do we really need another way to listen to our machine tools?

Courtesy of Arnold Engineering, Corona, Calif.

Machine shops produce a vast amount of data, and not all of it comes from CNC machine tools. Devices such as tool presetters, inspection equipment (such as the pictured device) and CAD/CAM systems are contribuing data, with MTConnect enabling users to pull data from them via Bluetooth connections.

"Yes," Edstrom said. Traditionally, machine tool controls and auxiliary manufacturing equipment have been like high school students waiting at the bus stop: They only talk to their friends. This might explain why so few shops collect data from their machine tools.

"Only about 2 percent of all shops monitor their shop floor," Edstrom explained. "I don't mean a stack light or a spreadsheet or somebody walking around with a clipboard. I mean honest-to-God access to a machine tool anytime, anywhere. The machine was given a command to go to some X, Y, Z position. Well, how close did it get to going there? How much time did it spend? You can't manage what you aren't measuring."

Even if you don't agree that there is a need for MTConnect, you have to admit he has a point. CNC equipment isn't getting any cheaper, good mach-inists are few and far between, and competitive pressure is increasing. Manufacturers need every edge they can get, yet the number of shops monitoring their CNC equipment is negligible. Why do so few companies choose to ignore the wealth of data available from their machine tools?

One Big Bandwagon

Apparently, Edstrom is not alone. Machine tool builders and control manufacturers alike have been pushing for many years toward open machine communication. Unfortunately for MTConnect, however, not everyone is singing out of the same hymnal. Siemens Industry Inc., Elk Grove, Ill., a supplier of CNC, motor, drive and communication technology to machine tool builders, promotes an open-platform strategy for its controls. Roger Hart, manager of R&D in the U.S., said, "Siemens supports connectivity to its Sinumerik controls through open-architecture tools available to machine tool builders and third-party integrators for manufacturing data communications protocols, including MTConnect."

Despite this vote of confidence, Edstrom pointed out that Siemens is not part of the MTConnect community. "Manufacturers around the globe would love to see them become an active member of the MTConnect Institute."

Nor is Haas Automation Inc. listed as a member of MTConnect. Kurt Zierhut, vice president of electrical engineering for Haas, said the Oxnard, Calif.-based company is only being pragmatic. "We have fewer than 50 customers a year asking about MTConnect. In spite of this, we are committed to providing an MTConnect-compliant interface, even though there is not yet a firm schedule for the development work necessary to achieve this."

This doesn't mean Haas is not interested in MTConnect, just that it has bigger fish to fry. Its M-Net interface, released several years ago, provides for a network connection to monitor machine tools. Even so, Zierhut said less than 1 percent of Haas customers use M-Net.

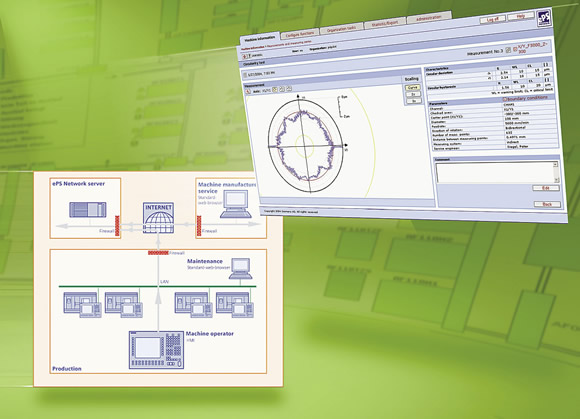

Courtesy of Siemens Industry

The ePS network services package from Siemens enable a machine builder, end user and Siemens to communicate in real time for predictive maintenance and machine-to-machine data comparisons.

And while FANUC FA America, Hoffman Estates, Ill., does offer an MTConnect interface, recent press releases suggest its support for the open-source standard is lukewarm. For example, it just introduced FASOPC for "easy retrieval of CNC machine production data" based on the OPC standard (Object Linking and Embedding for Process Control), established in 1996 by an industry task group with the same goal as MTConnect.

Edstrom is unconcerned. "We actually have a memorandum of understanding with the OPC Foundation and view them as partners," he said. "We've developed a joint specification called MTConnect-OPC UA (united architecture), and there's a white paper that talks about how we can work together."

While support for MTConnect is not universal, it has a substantial following. Earlier this year, Mazak Corp. offered a Webinar titled "MTConnect: Downstream Applications to Increase Productivity and Competitiveness." The Okuma America Corp. Web site lists MTConnect alongside the THINC-OSP control as part of the company's technology lineup.

And DMG / Mori Seiki USA Inc. recently announced its intent to offer an MTConnect V1.1-compliant adapter as standard on its MAPPS operating system. The company stated, "With preinstalled MTConnect adapters, DMG / Mori Seiki customers will have a plug-and-play solution that allows easy, real-time monitoring of their machines—from anywhere, at any time."

Courtesy of Siemens Industry

Through a secure Internet connection, Siemens ePS network services connect shop floor equipment to remote maintenance and repair facilities.

Surya Kommareddy, manager of software and technical sales for DMG / Mori Seiki, Hoffman Estates, Ill., indicated that traditional proprietary communication solutions are going the way of tin cans and string. "With MTConnect being an open standard, it allows customers to monitor all of their machine tools irrespective of the vendor. That's very appealing for them, and it's also good for us, because it allows for greater flexibility when integrating other equipment." Kommareddy quipped, "We wish everyone had a 'Mori Seiki only' shop. Until they do, we need an open standard."

The ability to facilitate communication with a variety of equipment types and brands is perhaps the greatest draw for would-be MTConnect adopters. Kommareddy said most shops have a mix of CNCs and struggle to come up with a comprehensive monitoring solution as a result.

Nowhere is this truer than on older legacy equipment, which often has nothing more than a serial port or no port at all. If you've got a shop full of those old dinosaurs, don't despair: break out the soldering iron.

According to Kommareddy, MTConnect-compliant input/output hardware devices are available and can be hardwired into the machine's programmable logic controller or even the light stack.

Boiling the Ocean

It's clear that companies following the MTConnect standard can turn even the most taciturn of machine tools into a Chatty Cathy, but this does little good without a means to convert all those 1s and 0s into meaningful information. This is probably the greatest value of a universal communication standard. Without a common library or data dictionary on which to code against, end users are forced to tweak their agents, modules and drivers to accommodate each machine tool or control builder's unique output.

Edstrom said MTConnect-enabled shops don't need to worry about this. Fed up with the poor support and high maintenance fees for your current machine monitoring software package? As long as the replacement can read from the MTConnect playbook, go ahead and ditch that old software. The owner of your shop buys new CNCs with the abandon of a compulsive gambler at a Vegas casino? No problem. "If the new equipment is MTConnect-enabled, just plug it in, assign an address and go," Edstrom said. Brand loyalty, at least from a machine monitoring software perspective, is irrelevant.

MTConnect might appear to be the best thing since sliced bread, but it does have limitations. For example, MTConnect will allow the development of software that tells when the machine is on fire, but it won't let that same software command the machine to turn it off. If you want to make a tool offset based on a measurement that just came down the MTConnect highway, you'll need to pass that information to another software package that can give the machine tool instructions.

That's because MTConnect is read-only, and Edstrom loses no sleep over it. "When we first developed MTConnect, we didn't want to boil the ocean. Bidirectional, or read/write, communication opens the door to all types of bells and whistles, but it also presents numerous safety concerns, so we took a do-no-harm approach. We can accomplish the goal of coordinating action and passing information through a read/read protocol, which means a coordinating piece of software listens for certain data and takes action accordingly. This is a better way to communicate and do it safely."

That's just fine with Yigal Ziv, president of Lemoine Multinational Technologies Inc., Walled Lake, Mich., which develops monitoring software based on the MTConnect standard. "The one-way nature of MTConnect fits our applications well," he said. "We're not interested in sending commands to the machine tool because there's already so much you can do by returning data from the manufacturing process: cycle time management, lean tooling, interaction with ERP systems, operator feedback, quality information … the list goes on."

And some might criticize the amount of data available through MTConnect adapters when compared to the interfaces from some machine tool builders. In some cases, MTConnect offers far less. Despite this limitation, Ziv is not one of those critics. He said: "Naturally, proprietary systems offer access to a lot more information than what is available from MTConnect, simply because MTConnect is trying to be a common denominator. Where you might get basic status information using MTConnect, some controls offer excellent packages that transmit very granular data. For example, FANUC Focas is quite deep, and Okuma THINC-OSP is as well."

Bring Your Own Code

Still want to have a two-way communication with your machine? Many builders support this, but you'll have to buy a proprietary interface. That or call someone like Chris Tacke, technical officer for FramTack LLC, a software development company in Cyer, Ind. Tacke said the majority of his company's work is with basic machine monitoring and MTConnect works quite well for this. When deeper integration is required, FramTack will write a custom interface.

"We've taken the MTConnect spec and added a bunch of things on top of it, allowing us to accept feedback from the machine and then put data back into the system based on that," he said.

Another company creating custom software is Itamco Inc., developers of an MTConnect client app for the iPhone and iPad, which lets you view machine controls anywhere there is cell service. You can download a copy from its Web site for free, but "You might want to pay for the 99 cent version—the free one has ads," Technology Manager Joel Neidig quipped.

Courtesy of DMG / Mori Seiki USA

The Mori-WebMonitor connects to any machine tool equipped with an MTConnect adapter, which sends machine information to a Web-based platform that is accessible via PC or mobile device.

Neidig admitted the app was a bit of marketing gimmickry, but the company's use of MTConnect is anything but. The Plymouth, Ind.-based company is not a development house—it's a precision machine shop, with nearly 200 machine tools and a real need to monitor every one. "We have a menagerie of CNC equipment, over 30 different types of manufacturers and control makers, and a lot of it is old stuff," Neidig said. "We're even planning to hook up our air compressors, presetters and inspection equipment. That's why MTConnect has been huge for us, because none of those communicate with each other out of the box."

Collaborating with MTConnect sponsor TechSolve Inc. in nearby Cincinnati, Itamco has worked for the past year on a project to connect everything in the shop to ShopViz, a central machine monitoring system. It's about 25 percent complete.

Aside from the aforementioned benefits of machine tool monitoring, Itamco has seen some surprising results. By tracking power consumption on its equipment, Itamco reduced its energy costs. Neidig said: "Our utility company charges a much higher rate if we exceed the base level during peak hours. Because we can now monitor that real-time, we found that we could schedule jobs based on that usage. We cut our electric bill—roughly 14 percent of our total operating expenses—by more than 30 percent."

Armchair Quarterbacks

Many people would like to see a more robust communication standard than that offered by MTConnect, one that offers a rich feature set and two-way communication with all industrial equipment. For that matter, manufacturers should expect the same level of connectivity from their expensive CNC equipment as they do from their smartphones, smart TVs and Bluetooth-enabled cars. But in all fairness, Edstrom is right. Most shops are disinclined to even monitor their machines, let alone establish meaningful dialogue with them. Until more companies start utilizing what's already possible with MTConnect, there's no reason to gripe about what it isn't.

Machine tool monitoring and automation are two important tools for U.S. shops to beat their competition located in low-labor-cost countries, and it's high time the manufacturing industry joins the fight. So get listening. CTE

Contributors

DMG / Mori Seiki USA Inc.

(847) 593-5400

www.dmgmoriseikiusa.com

FramTack LLC

(240) 293-4633

www.solution-family.com

Haas Automation Inc.

(800) 331-6746

www.haascnc.com

Itamco Inc.

(574) 936-2112

www.itamco.com

Lemoine Multinational Technologies Inc.

(248) 960-5989

www.lemoinetechnologies.com

MTConnect Institute

(703) 829-6059

www.mtconnect.org

Siemens Industry Inc.

(800) 241-4453

www.usa.siemens.com/cnc