Making turbines more efficient

Making turbines more efficient

Scientists in Japan study metals with niobium silicide in hopes of developing more high-tolerant turbine components.

Metals containing niobium silicide are promising materials that can withstand high temperatures and improve efficiency of gas turbines in power plants and aircraft. But it has been difficult to accurately determine mechanical properties of these metals due to their complex crystal structures.

Scientists at Kyoto University in Japan now have measured what happens at the microlevel when pressure is applied to tiny samples of these materials. The approach, which was published in the journal Science and Technology of Advanced Materials, could help scientists obtain the accurate measurements needed to understand the atomic-level behavior of complex crystals and develop more heat-tolerant components for gas turbines.

"Our results demonstrate the cutting edge of research into plastic deformation behavior in crystalline materials," said study corresponding author Kyosuke Kishida.

Plastic deformation describes the distortion that occurs at the atomic level when a sustained force is applied to a crystal. This is difficult to measure in complex crystals. He and his colleagues have been using a new approach to systematically measure plastic deformation in crystals showing promise for use in high-temperature gas turbines.

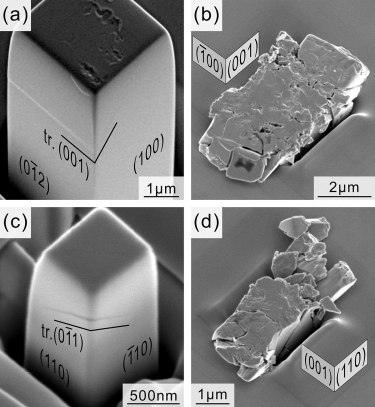

Shown are scanning electron microscopy secondary electron images of deformed micropillar specimens with the four loading axis orientations tested in the study.

Researchers measured plastic deformation in a niobium silicide called α-Nb5Si3. Tiny "micropillars" of these crystals were exposed to very small amounts of stress using a machine with a flat-punch indenter at its end. The stress was applied to different faces of the sample to determine where and how plastic deformation occurs in the crystal. By using scanning electron microscopy on the samples before and after the test, scientists were able to detect the planes and directions in which deformation took place. This was followed by simulation studies based on theoretical calculations to further understand what was happening at the atomic level. Finally, the team compared the results with those of a boron-containing molybdenum silicide, or Mo5SiB2, that the researchers previously had examined.

"We found that instantaneous failure occurs rather easily in α-Nb5Si3," Kishida said, "which is in marked contrast to Mo5SiB2."

This could mean that α-Nb5Si3 is at a disadvantage compared with Mo5SiB2 for use as a strengthening component in metal-based alloys. However, he and his team think that the inherent brittleness of this material could be improved by adding other alloying elements.

The team plans to use the approach to study mechanical properties of other crystalline materials with complex structures.

— ResearchSEA