Micromachining: The art and science of micro-moldmaking

Micromachining: The art and science of micro-moldmaking

Three primary elements play a heightened role when machining molds for plastic injection molding of microparts compared to moldmaking for the macro realm: part size, feature size and dimensional tolerances.

Three primary elements play a heightened role when machining molds for plastic injection molding of microparts compared to moldmaking for the macro realm: part size, feature size and dimensional tolerances.

"Each one of those elements factor in," said Aaron Johnson, vice president of marketing and customer strategy for micromolding specialist Accumold. "Or all three [do], in a lot of cases."

In addition to machining the steel molds and using them to produce plastic parts, the Ankeny, Iowa, company manufactures the cutting tools it applies for moldmaking. "We feel that for this type of molding, vertical integration is essential to successful molding," Johnson said. "We produce 100 percent of our tools in-house because the relationship between the cutting tools, the steel cutting and the processing is a very close relationship."

A cavity insert created by MTD Micro Molding is part of a four-cavity micromold. The cavity insert measures less than 1"×1". Image courtesy of MTD Micro Molding.

The amount of plastic needed to mold a micropart is typically less than 1g (0.035 oz.). Therefore, managing the material, controlling part shrinkage and ensuring variables like the mold having the appropriate draft angle are even more critical with micromolding, he noted.

However, a molded part doesn't necessarily have to be super small to be considered "micro." "We do larger parts that have micro features and tolerances," Johnson said, noting those can include parts with microfluidic channels and tolerances from 25µm to 2µm (0.00098" to 0.00008"). "There are even submicron-size features."

According to Johnson, conventional molders can't perform these types of moldmaking and molding applications. "There are a lot of small things out there, but if you are finding that 50 molders on your vendor list can do it, then, from our perspective, it is not true micromolding," he said. "I don't want to define [micromolding] too closely, because there are so many variables involved. Usually, you know it when you're struggling to get it made."

The Medical Market

Many molds are machined to produce complex micro parts and devices for the medical industry, partly because the smaller something is, the less invasive the process is for placing it into the human body.

"The medical device industry leaps ahead almost daily, with constant demand for smaller, never-before-seen micro medical devices," said John Clark, project manager for MTD Micro Molding. "And ultraprecise micro medical components are the result of exact tooling execution."

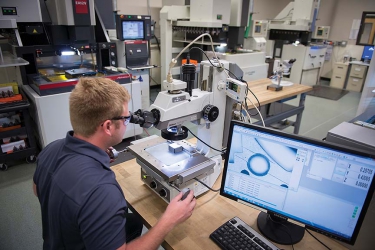

A technician inspects a mold in Accumold's toolroom. Image courtesy of Accumold.

The Charlton, Mass., company is 100 percent focused on serving the medical industry. The molds MTD machines include two- and three-plate molds, as well as overmolds. (Editor's note: An overmold is a part molded from one material that has a second material molded over the first. A toothbrush with a soft-grip handle is an example of an overmold.)

Carl Lemieux, MTD's tooling supervisor, conceded that the processes for machining micromolds follow the same fundamental material-removal principles as making macroscale molds. He noted, however, the main differentiating challenge is the heightened focus on tolerances. A typical tolerance for an MTD micromold, taking into account all the factors of a client's product design, is ±0.0001" (2.54µm), he said, noting a red-blood cell is 6µm to 8µm in diameter.

Achieving that level can be tricky when applying cutting tools smaller than 0.010" (0.254mm) in diameter with length-to-diameter ratios of 5:1 to 8:1, according to Lemieux. "In a situation where this doesn't work, we typically have to laminate the cavity or electrodes to accommodate what cutting tools are available to us."

Lemieux added that the primary considerations for cutting tool selection are the workpiece material and the specifications of a mold's inside corner radii.

Clark explained that all MTD's mold cavities are machined via sinker EDM to achieve the most "model-like" finished component, while the mold bases are milled, with air or high-pressure coolant applied to manage chips when roughing.

An MTD technician at corrects electrodes on a sinker EDM. Image courtesy of MTD Micro Molding.

To achieve the required tolerances on its milling machines, MTD uses laser touch-off systems because lasers can measure tool length and diameter much more accurately than a human can, Clark said. "It allows for a better blend from one tool to another, keeping the relationship from one tool to another highly accurate, which is critical in microtool building."

The milling machines themselves are run beyond the machine tool builder's documented capability specifications to create the tiny, complex designs, Clark added. "We push all our machine tools past their limits."

The extra effort put forth is to achieve a high level of repeatability and part accuracy, and not to boost throughput. "Speed is not as important to us," Clark said, adding that the focus on machining ultraprecise molds to produce high-quality micro medical components is "absolutely" causing demand to grow.

Accumold's Johnson concurred that exceeding the expected capabilities of its manufacturing equipment is essential to micro-moldmaking success. "Even some of the manufacturers say, 'You're getting our machines to do more than what we can do with them,' " he said, adding that regular machine calibration is critical to keeping them cutting

accurately.

On a sidenote

Growing the Future

Demand for Accumold's parts is stronger than ever, according to the Iowa company.

"We have added over 100 employees to our team in all areas of our business in the last 12 months," said the micromolder's Aaron Johnson, adding that Accumold has 340 employees. "We are continuing to grow and had our third expansion to our facility in the middle of last year," Johnson said. The facility has 130,000 sq. ft. of space.

Nonetheless, similar to any machining operation, achieving that growth isn't possible without trained and talented employees. That's where Accumold Scholars, a scholarship program sponsored by Accumold and Des Moines Area Community College, steps up to the plate. Three paths are available for DMACC students in the program: tool and die making, robotics and control systems engineering technology, and applied engineering technologies and electromechanical technologies. Up to five scholarships are awarded each year.

Scholarship recipients "get to work on our production team while finishing their technical credits at that school," Johnson said. "When they graduate, the goal is to bring them in full-time, either in the toolroom, on the automation and robotics side of our business, or in maintenance. We even have a maintenance scholarship. That is a way of growing our own future."

Johnson emphasized that with the proper training, tool and die makers can begin the process of putting the pieces of the molding tool puzzle together so they line up perfectly. "The entire tool has to be a piece of art."

—A. Richter