Salary rebound

Salary rebound

Cutting Tool Engineering magazine's biennial salary survey for 2014 shows the earnings of metalworking professionals heading upward.

Following the salaries of metalworking professionals is like watching a hot air baloon—at one point they're down and a couple years later they're up. Cutting Tool Engineering's Eighth Biennial Salary Survey reveals their movement, and the trajectory is up.

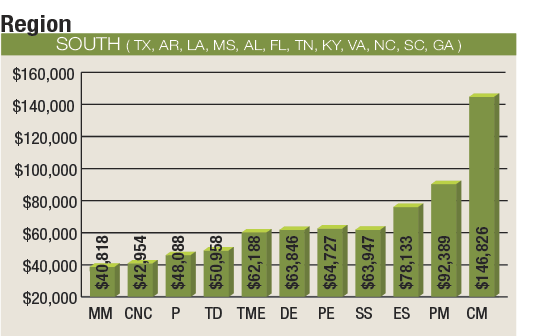

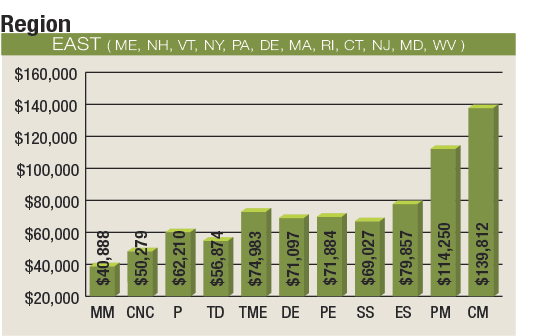

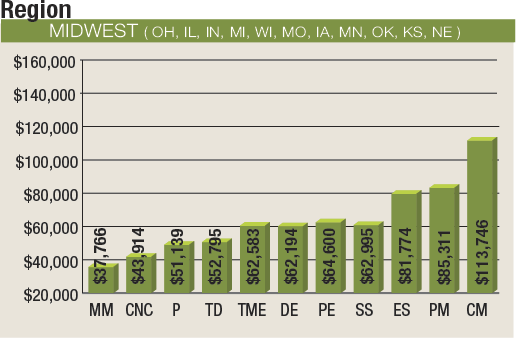

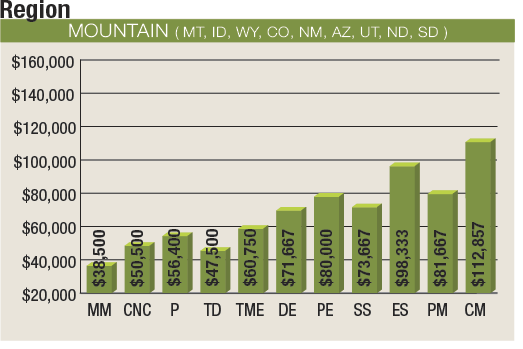

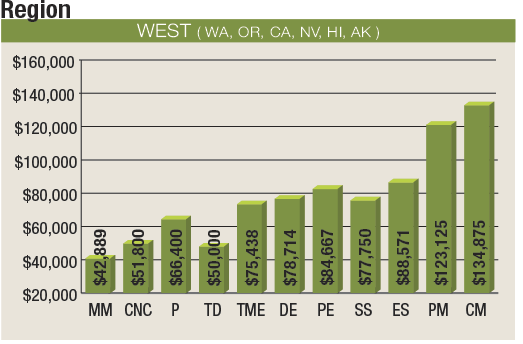

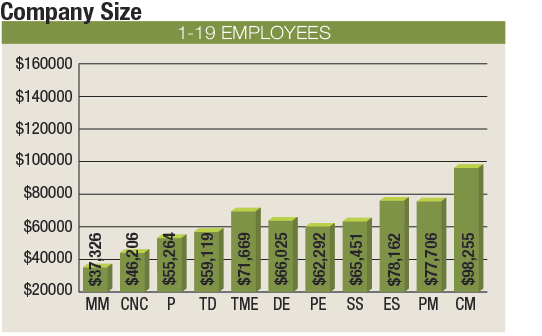

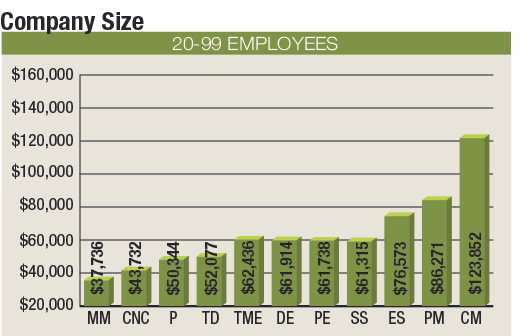

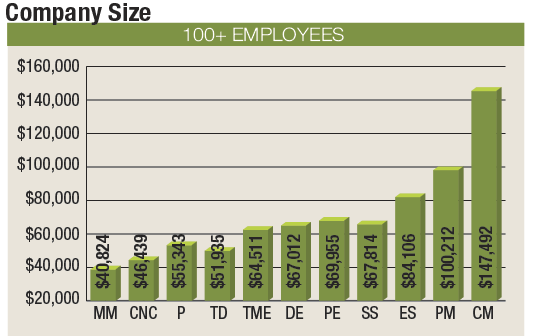

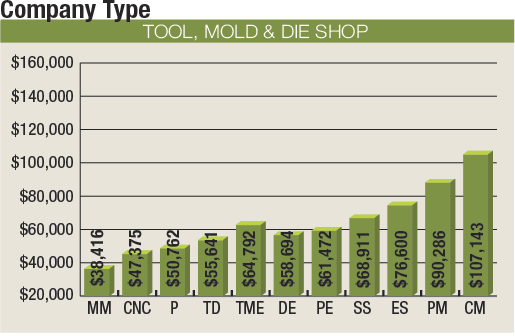

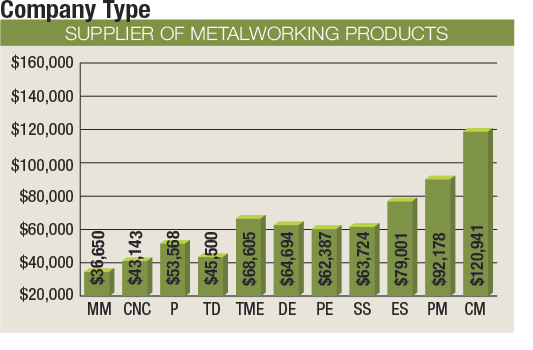

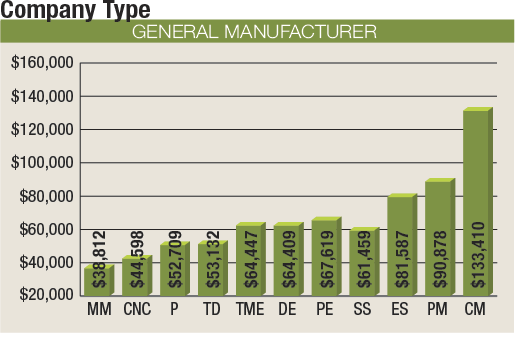

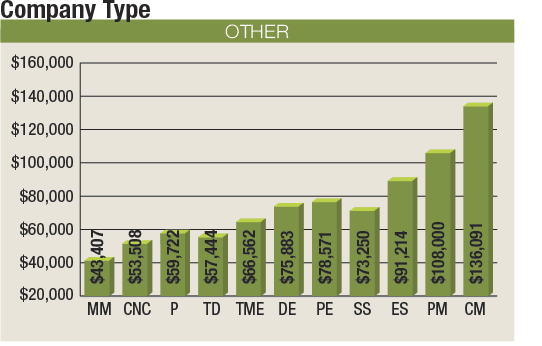

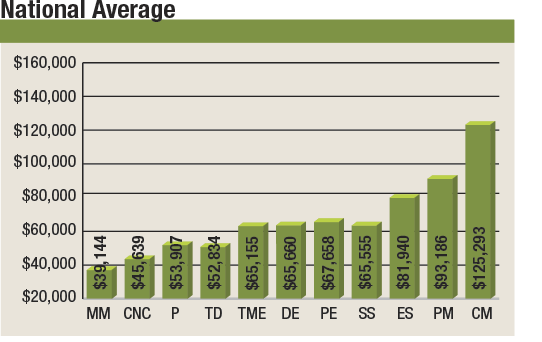

Similar to past surveys, the top breadwinners are corporate managers, averaging $125,293. This is $22,730, or 22.2 percent, more than 2012. Unlike the last survey, no position registered a decline, but CNC machinists gained the least, with their pay only increasing $24, or 0.05 percent, on average from 2 years ago.

Plant managers were the biggest gainers percentagewise from 2012, increasing $18,905, or 25.4 percent, on average to $93,186. This reverses a 4.7 percent drop in pay from 2010 to 2012.

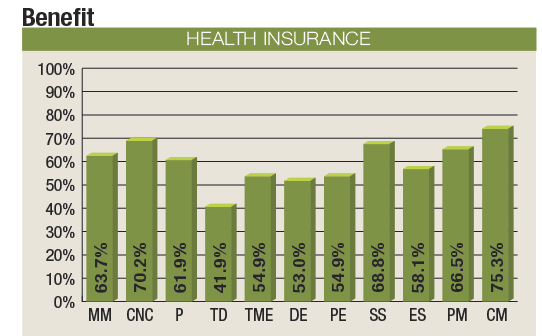

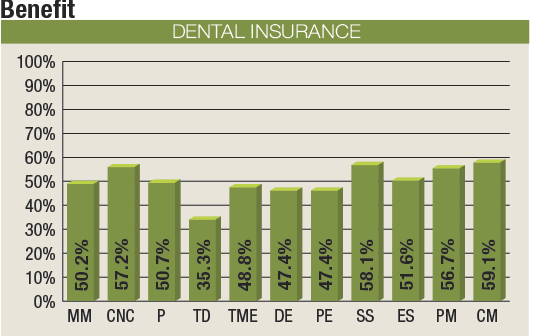

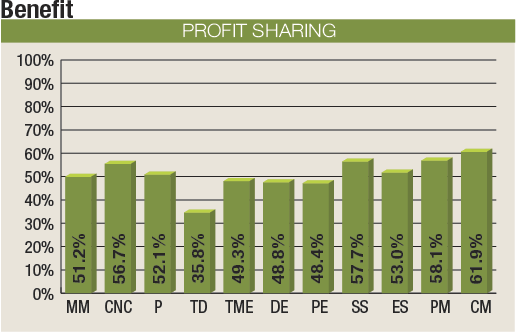

Reversing the trend revealed in the 2012 survey, all positions saw an across-the-board increase in nearly all benefits: health insurance, dental insurance, profit sharing/401(k), paid training/continuing education and use of a company car. For example, 70.2 percent of CNC machinists now receive company-provided health insurance compared to 56.1 percent in 2012, an increase of 14.1 percent. Compared to the 2012 results, in which the majority of only two positions (CNC machinist and corporate management) received health insurance as a benefit, only tool and die makers are below the 50 percentile at 41.9 percent in this year's survey.

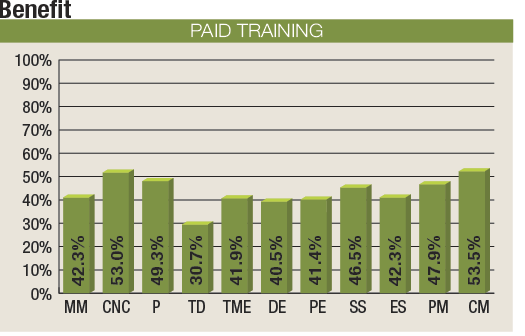

While the majority of most positions in the survey don't receive paid training, with the exception of CNC machinists and corporate managers at a respective 53.0 and 53.5 percent, a higher percentage of all positions receive this benefit compared to 2012. This is probably a result of companies realizing the productivity and bottom-line gains a trained and educated workforce provides and having the funds to facilitate it.

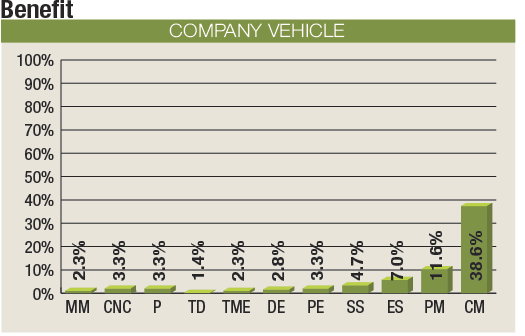

Fewer manual machinists, shop supervisors, plant managers and even corporate managers, however, will be tooling around town in a company vehicle. The percentage of manual machinists who receive that benefit, which was always small, fell to 2.3 percent in 2014 from 2.6 percent in 2012. On the other side of the spectrum, most corporate managers had use of a company vehicle in 2012 (59.3 percent), but only 38.6 percent did in 2014, a drop of 20.7 percent. Nonetheless, the top dogs who no longer get that perk likely can afford a vehicle of their choosing.

Similar to the 2012 survey, CTE used e-mail to collect survey data from owners and managers of parts manufacturing companies who subscribe to the magazine. The e-mail directed them to a Web-based survey that requested average annual salaries and benefits for themselves and their employees.

CTE sent 9,440 e-mails and received 215 responses.

The average salary was calculated according to the arithmetic mean. For example, if four recipients indicated their programmers earn average annual salaries, even when calculated from an hourly wage, of $46,000, $59,000, $51,000 and $53,000, the mean would equal $52,250 ([46,000 + 59,000 + 51,000 + 53,000] ÷ 4 = 52,250).

The benefit percentages were calculated by dividing the total number of positive replies for a specific benefit by the total number of respondents. For example, if 105 respondents indicated that their CNC machinists receive company-paid dental insurance, the percentage receiving that benefit would be 48.8 percent (105 ÷ 215 = 0.4883). CTE