Self-starter

Self-starter

Connecticut Spring & Stamping developed an apprenticeship program to meet is own training needs.

Courtesy of All images in main article: Robert Pierpont, CSS

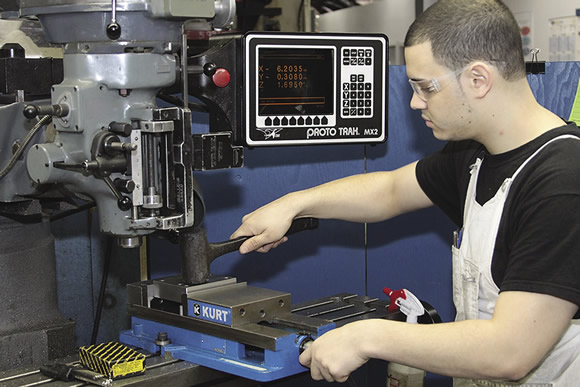

Toolmaker Alex Pabon has been working at CSS for 5 years and credits the company's apprenticeship program for opening doors to him that would not have been otherwise.

|

Training is vital to the future of U.S. manufacturing, yet it appears to be in short supply. Training for skilled manufacturing jobs has been hit by a perfect storm of budget cuts and the mistaken idea that all high school students should attend college. As a result, it is difficult to fill critical positions with trained workers.

At our company, Farmington, Conn.-based Connecticut Spring & Stamping, which has more than 420 employees at facilities in the U.S., Puerto Rico, Mexico and Asia, the situation had become so desperate that, to meet capacity and continue to grow, we had to replace state-funded training with our own programs. These new programs are tailored to the skill sets required for tool and die makers and various spring coiler setup operations.

Rapid Growth

Our company, growing at about 20 to 30 percent per year, has struggled for the past decade to find qualified workers. For 4 decades before that, CSS and other manufacturers relied on state-supported manufacturing sciences programs at local colleges and technical schools to provide training, including tool and die making and spring coiler setup—but no longer.

"As the manufacturing companies and jobs migrated to the south or overseas, the state lost interest and stopped funding these programs," said Steve Dicke, vice president of sales and marketing at CSS. "We would run an ad for a spring setup person and would rarely get any applicants with the proper training."

Many likely candidates were pursuing computer programming training. Although the manufacturing jobs at our shop require computer literacy, they also require an additional set of manual skills—the ability to effectively maneuver parts and machines.

We have had to rely on overtime in the short term. "Managers are working longer hours and are leaning harder on key employees to support customer needs," Dicke said. "In addition, we do not take on a new opportunity unless we know we can fully support it."

Falling by the Wayside

To become a certified skilled worker in Connecticut, individuals must complete apprenticeships comprised of 6,000 to 8,000 hours of on-the-job training. The actual number of hours depends on the specific job, with toolmakers requiring the most training, and workers must also complete 432 to 600 hours of related school-based training. CSS and other companies offering apprenticeships must be registered with the state apprenticeship program.

CSS expects that workers will complete the company's apprenticeship program and get to competency level in about 3,000 hours.

Our apprenticeship program is based on completion of a set of work standards, including turning, horizontal and vertical milling, grinding, drilling, sawing and cutoff, as well as orientation, bench assembly and related training at a technical school.

In the past, apprentices received this related training at trade schools, such as the nearby E.C. Goodwin Technical School, attending about 4 hours per week during working hours as part of the required program. Apprentices were graded on their knowledge and placed in a program based on skill level. They would be given credit towards the related training hours for skills they already had.

Today, the on-the-job and related training requirements remain the same, but rather than being placed in programs to match their skill level and receive credit for skills they have, apprentices are forced to take full- semester evening courses. For example, we have two apprentices close to completing the state apprenticeship process but they have been frustrated with the 500-hour schooling component. They have nowhere to go to take the specific classes they need. Instead, they have to take time off from work and attend a group of courses, not all of which are relevant because the programs seem to be more focused on college aptitudes than manufacturing skills.

We have approached vocational high schools to run courses but found their emphasis to be on training nurses, electricians, carpenters and similar professions. The schools have told us that there are not enough people for them to offer these courses, but we know the jobs are there.

Bridging the Gap

In 2012, CSS created an in-house apprenticeship program, including tracks for CNC production setup, press and fourslide die makers, stamping press setup operators, fourslide setup operators and heat-set setup operators. The apprenticeship program is only offered to current CSS employees looking to advance and requires just a high school diploma or GED.

Under the direction of a training instructor, who must have a high school diploma and be a full-time employee, and using the same guidelines established by the state apprenticeship program, apprentices are trained in tasks assigned to each competency—basic, intermediate and advanced—for each position.

Brian Mills, an auto power press setup apprentice (pictured above and below), said the apprenticeship program has given him a goal and makes the job more interesting.

The formal, structured program gives apprentices a defined career path. After completing each competency, apprentices receive a raise, which varies based on the length of the program but is roughly 10 percent per competency. There is no timeline associated with each competency and each apprentice learns at his or her own pace. In addition, we have our own certificates and clear manager-defined functions, techniques and skills for each position.

The expectation is that workers will complete the program in about 3,000 hours. Required training is handled by crediting apprentices for what they already know, while identifying any weaknesses and providing the training needed to correct them. When a skilled employee works with an apprentice and the person is having a problem with blueprint reading or shop math, we send them to a class or even bring the training in-house.

A gender and ethnically diverse group of 11 people are enrolled in the program, working 8 hours a day, 5 days a week. As they advance, we will promote more employees into the program, and the number will be based on when the enrolled people complete the program.

There are no graduates yet, but the first crop is well on its way and two or three candidates should complete their programs during the first quarter of 2014. For example, 23-year-old toolmaker Alex Pabon has been working at CSS for 5 years and credits the program with creating new opportunities. "It has helped me better understand how things are made and how important it is to make it right the first time," he said. "The trainers are easy to talk to, and, if you have any questions, they go out of their way to make sure you understand."

On the Job Growth

Brian Mills, a 24-year-old auto power press setup apprentice who will graduate soon, said the program has given him a goal and makes the job more interesting.

"When I first started here as an operator and watched the setup people at work, it looked hard and very confusing," he said, "so when I heard about the apprenticeship program I was nervous and skeptical about joining. But once I did, it was a smooth ride and not as hard as I thought. Once I'm done, I want to keep moving forward and make a good career for myself."

The cost of the program is only about $5,000 to $10,000 per candidate based on the skill level, but we estimate a 20 to 30 percent weekly efficiency loss associated with having a skilled employee training an apprentice.

To fund the program, we use available grants, including the Connecticut Department of Labor's 21st Century Skills Training Program and the Connecticut Center for Advanced Technology Inc.'s ADVANCE Training Grant Program.

While our apprenticeship program is clearly a success, we still would prefer to focus solely on manufacturing and not take the place of educational institutions. We created the program to fill a void, and the program enables us to promote from within its own ranks. There is a glimmer of hope on the horizon, as a few technical institutions and local community colleges have recently been putting out feelers concerning potential training programs and internships, possibly in response to requests from other manufacturers. CTE

EMAG participates in jobs training initiative

Machine tool builder EMAG LLC is participating in the Michigan New Jobs Training Program initiative, led by Sen. Debbie Stabenow (D-Mich.). She is also introducing legislation in Congress, called the New Skills for New Jobs Act, which would provide federal funds to match state training reimbursements, so repayment to colleges would occur quickly. This would assist states that have already begun helping community colleges to create more training and retraining opportunities.

Courtesy of EMAG

Peter Loetzner, CEO of EMAG, discusses the new Michigan jobs training initiative with Sen. Debbie Stabenow at Oakland Community College's Advanced Technology Center.

EMAG, Farmington Hills, Mich., already supports MAT2 (Michigan Advanced Technician Training), in conjunction with Oakland Community College and Henry Ford College, in which students that complete a work/study program have guaranteed employment at the end of a defined period. "We see the New Jobs Training Program as a logical extension of the student program, as many in the current workforce need enhanced skills to perform the new tasks required by today's technology," said EMAG CEO Peter Loetzner.

According to Sen. Stabenow, her bill would increase the number of eligible companies and workers participating in the Michigan New Jobs Training Program, which trained nearly 10,000 workers in partnership with 44 companies last year. "This program is a partnership between businesses and the community colleges, reaching out to workers," she said. "And it's a way for the federal government to recognize that new job skills training—to match the jobs now available—is a top priority for moving the economy forward."

SaveSave