Simpler shop floor CMM

Simpler shop floor CMM

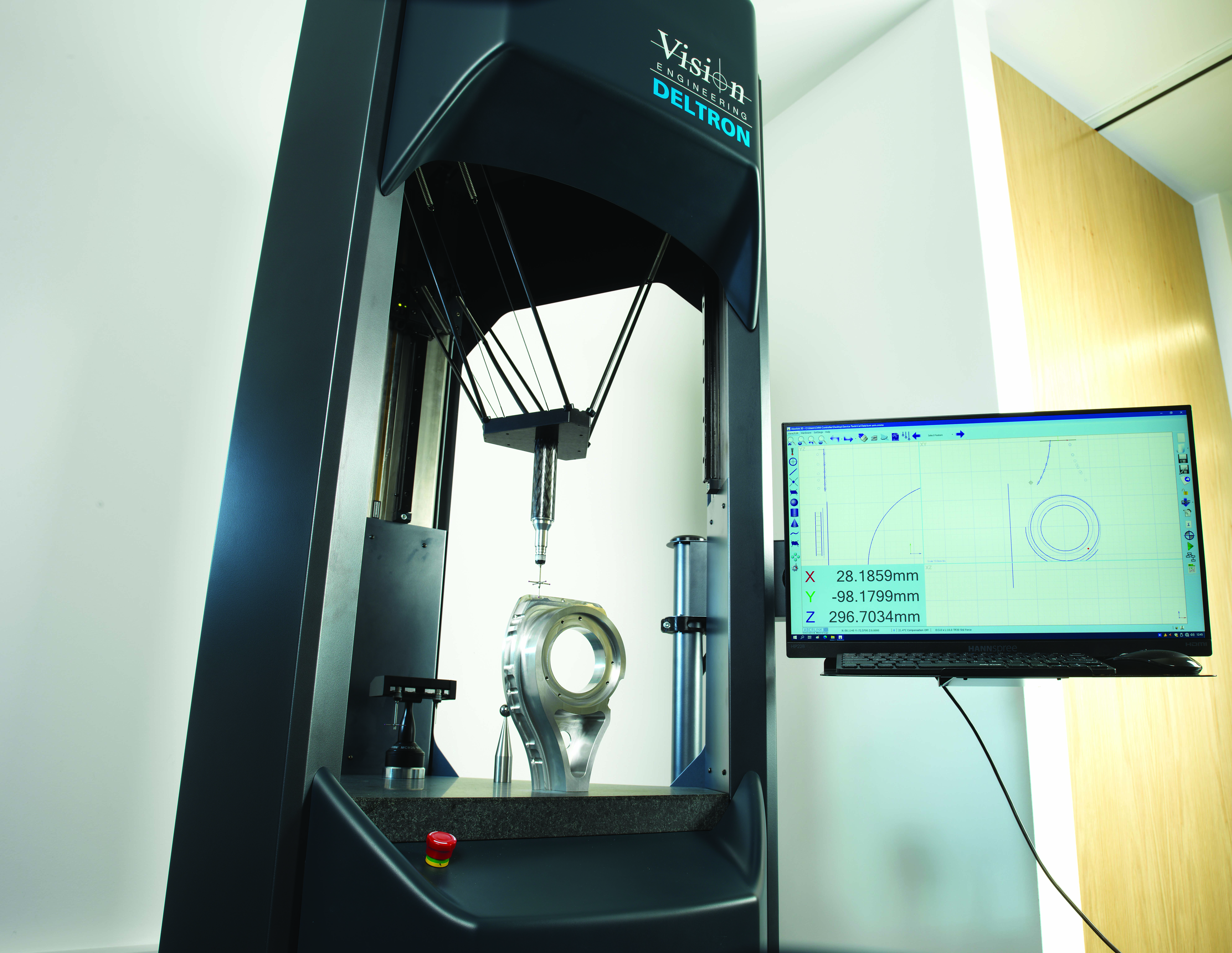

New Deltron design enables probe to go where it needs to be.

Machine shops stand to benefit in many ways from a different approach to measuring-machine design.

The innovative design is the brainchild of U.K.-based Aberlink Ltd. Another firm headquartered in the United Kingdom, Vision Engineering Ltd., is selling Aberlink's device under the name Deltron. (Vision Engineering Inc. is in New Milford, Connecticut.) The shop-floor-hardened Deltron is a non-Cartesian coordinate measuring machine featuring a delta robotic mechanism.

Delta robots commonly are used to move objects quickly and accurately in pick-and-place operations, said Güven Türemen, group metrology manager at Vision Engineering.

"So Aberlink thought, 'Why don't we use that (technology) to move a probe?'" he said.

Deltron's probe is held in place by three pairs of carbon-fiber rods. Türemen said the mechanism looks and operates nothing like a typical CMM.

"Typically, you have Cartesian machines where the probe moves in the x-, y- and z-axes individually," he said. "With the Deltron construction, the probe just goes where it needs to be following the shortest route. It doesn't have to move first in z, then x, then y."

Featuring a delta robotic mechanism, the Deltron coordinate measuring machine is designed to be used on shop floors. Image courtesy of Vision Engineering

Deltron's design offers maximum point-to-point speed and acceleration of 500 mm/s (19.7") and 750 mm/s2 (29.5"), respectively, according to Vision Engineering.

It's also a much simpler mechanism than traditional CMMs, Türemen said, which translates into a smaller footprint on the shop floor.

"Now you can see a lot of equipment crammed into a machine shop so that (many) operations can be completed there and then rather than moving stuff between the manufacturing floor and a lab," he said. "So it's becoming more important that anything you use on your shop floor doesn't take up too much real estate. Largely due to the delta mechanism incorporated, the Deltron takes up significantly less space" than a Cartesian machine.

Türemen said a simpler mechanism also keeps the build cost low. This is reflected in Deltron's selling price, which he said is less on average than conventional CMMs with similar specifications.

Deltron's cylindrical measuring volume measures 370 mm (14.6") in diameter by 270 mm (10.6") in height. He said the measurement accuracy of the machine is due in part to design features that deal with ambient temperature variations.

"Quality labs have a stable temperature that's usually around 20 degrees Celsius (68 degrees Fahrenheit)," Türemen said. "But the Deltron being a shop floor machine, the temperature variations (it experiences) can be quite big, and that is a challenge for measuring systems."

To minimize the effects of temperature and thermal expansion, the machine is equipped with five sensors that monitor changes in ambient temperature. Using that data, he said, the system's software automatically applies temperature compensation so measurement results are always the same as if they were taken at 20 C.

Vision Engineering also attributes Deltron's measuring accuracy in part to the machine's 0.1 µm (0.000004") resolution scales and a granite table that holds samples weighing up to 200 kg (440 lbs.). Türemen said the table doesn't expand or contract with ambient temperature variations and provides greater stability than a steel or an aluminum base.

Another key Deltron feature he cited is its bearings. While typical CMMs have air bearings, Deltron is equipped with mechanical bearings, which means that the machine doesn't need to be near a source of compressed air and therefore can be positioned exactly where the machine is needed. He said the device's machine tool-grade mechanical bearings won't disappoint when it comes to measurement accuracy.

Deltron also includes ViTouch3D, which Vision Engineering describes as user-friendly software suitable for a variety of functions. Türemen believes that this software should lessen the concerns of those who wonder if machine operators will be up to the job of operating a CMM.

A shop floor CMM "can be quite intimidating to people who might think it will be very complicated," he said. "So the most important advantage of the machine (software) is that it's really easy to use compared to other CMM software packages."