Sparkling Performance

Sparkling Performance

Author discusses the advantages of CVD-diamond tools compared to other types of diamond tools. He also explains how CVD-diamond tools are manufactured and gives case histories involving their usage.

CVD-diamond tools perform at levels that exceed the capabilities of other diamond tooling.

CVD diamond can be vapor-deposited in freestanding forms such as the large 7"-dia. discs shown in the background. Freestanding wafers are laser-cut into a wide range of shapes that are used by the cutting and dressing tool industry.

The unique combination of properties that diamond possesses makes it an excellent material for a wide range of precision and high-productivity industrial applications.

From the single-crystal synthetic diamond produced at high temperatures and under tremendous pressures (HTHP), which was introduced in the 1950s, to the metal-sintered polycrystalline diamond developed in the 1970s, synthetic-diamond materials have created unique alternatives to natural single-crystal diamonds. And with the recent emergence of pure polycrystalline-diamond material applied by the chemical vapor deposition (CVD) process, there is the potential to raise tooling performance to levels once thought impossible.

The range of industrial uses for CVD diamond is impressive—from wear-resistant coatings to pure, freestanding material used in high-tech optics and electronic components. But of primary interest to the machining industry is the practical application of CVD-diamond material in high-performance cutting tools and dressing tools (see accompanying article).

Unlike HTHP diamond and metal-sintered PCD, the manufacture of CVD diamond does not require the high pressures needed to mimic the forces of nature deep within the Earth. Instead, CVD diamond is synthesized using high-temperature, low-pressure gases contained within special vacuum chambers (Figure 1). In these "reactors," hydrogen- and hydrocarbon-gas mixtures are energized to an "activated" glowing state that does not normally exist in nature. This activated chemistry allows pure, CVD polycrystalline diamond to be deposited at temperatures ranging from 800° to 1,100° C.

Figure 1. CVD diamond can be produced using several different methods, including microwave-assisted, arc-jet and hot-filament (not shown) deposition.

Thin and Thick

The most widely recognized application of this technology in today's marketplace is "thin-film" CVD-diamond coatings for tungsten-carbide cutting tools. Diamond-coated tools ranging from chipbreaker-style inserts to fully coated helical endmills are commercially available.

But a "thick-film" CVD-diamond process is also available for producing solid forms of pure, binder-free diamond. The typical thickness of these forms ranges from 150µm to 1,000µm. The material is first vapor-deposited in the form of a freestanding wafer that is then laser-cut into a variety of shapes for the specific cutting tool application. The raw material is usually polished to a mirror finish, similar to a polished PCD.

Pure CVD-diamond wafers contain no metallic binders and, therefore, do not possess the conductive properties necessary to allow them to be cut by a wire-type electrical discharge machine. The general acceptance of using a wire-EDM to fabricate PCD tools, and the present lack of the necessary laser equipment at tool manufacturers, means that toolmakers wanting to produce thick-film CVD-diamond tools must purchase precut shapes directly from a diamond-material supplier.

Quite a Combo

The advantages of CVD diamond as a cutting tool material result from a combination of properties that go well beyond diamond's unmatched hardness.

Unlike metal-sintered PCD, the unique properties of a natural diamond are generally retained in CVD diamond—even at elevated cutting temperatures. The hardness and elastic modulus of single-crystal diamond contributes to CVD diamond's excellent resistance to abrasive wear, as well as its dimensional stability.

In a silicon-carbide "sandblasting" test, the relative volume-loss of freestanding CVD diamond was four times lower than PCD and 120 times lower than tungsten carbide. Unlike metal-bonded PCD compacts, thick-film CVD-diamond material can match—and even exceed—the hardness and wear resistance of a single-crystal diamond at elevated cutting temperatures.

And, like natural diamond, CVD diamond has a low coefficient of friction. This contributes to lower cutting forces and power consumption, less frictional heating and excellent resistance to BUE while cutting. The reduced cutting temperature caused by CVD diamond's high lubricity is a major advantage over PCD and other materials when dry or high-speed machining.

CVD diamond offers other benefits. Thick-film CVD-diamond materials that are engineered for mechanical applications generally have a heat-transfer efficiency that is five times greater than tungsten carbide and 50 percent higher than PCD. A CVD diamond's excellent thermal conductivity acts as a safeguard by dissipating the heat generated in the cutting zone.

The binder-free structure of CVD diamond allows the creation of tooling that can withstand aggressive machining temperatures—those approaching 800° C. By contrast, cobalt-sintered PCD is susceptible to thermal damage as machining temperatures approach 700° C. While there are cobalt-leached forms of PCD available to combat this cobalt-induced degradation, CVD diamond still offers superior wear resistance.

The binder-free structure of CVD diamond is chemically stable, compared to metal-sintered PCD and tungsten-carbide materials. CVD-diamond-coated tools last significantly longer when machining corrosive polymers, such as the phenolic resins used in composite materials. CVD diamond also is resistant to the corrosive damage caused by cutting tool fluids.

However, the chemical instability that arises with pure diamond and metal alloys containing iron, nickel or cobalt has historically limited diamond's use in the cutting of ferrous materials and superalloys. Even so, applications exist where diamond materials, such as PCD, single-crystal and CVD diamond, are preferred for high-productivity ferrous machining. Automotive deck-face machining—across the cast iron piston liners in an aluminum engine block—is a good example of an application where the unique properties of PCD has overcome the typical chemical limitations of ferrous machining.

Built Tough

Freestanding CVD diamond can be used as an alternative to metal-sintered PCD to fabricate diamond tooling.

Due to its polycrystalline structure, CVD diamond can be engineered to have a fracture toughness (crack resistance) that actually exceeds natural diamond. This proves advantageous in aggressive machining operations, such as interrupted cutting and wheel dressing.

In general, the mechanical integrity of CVD diamond is similar to an advanced ceramic's. And like natural diamond, CVD diamond offers exceptional wear resistance. Similarly, though, users must understand that CVD-diamond tools require the same careful handling as a natural-diamond or ceramic tool.

The ability to fine-tune the fracture toughness, strength and other critical properties of CVD-diamond freestanding wafers offers the potential to improve the high-performance tooling used in applications ranging from CNC rotary dressing wheels to the high-speed, near-dry machining of aluminum and metal-matrix composites.

CVD-diamond and PCD tools are fabricated in a similar fashion. The diamond tip is brazed to a notched corner of a tungsten-carbide or HSS tool body. The tool is then finish-ground with a diamond wheel.

Robust brazing techniques for thick-film diamond tips were developed in the early 1990s, solving the adhesion and substrate-selection challenges that continue to negatively impact a broader acceptance of thin-film, diamond-coated carbide tips for metalcutting operations.

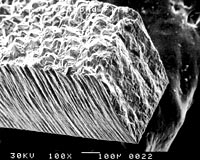

Most of the freestanding, thick-film CVD-diamond material used in cutting tools is approximately 0.5mm thick (Figure 2). The relatively smooth and fine-grained (~1µm) nucleate surface is typically polished and serves as the rake face of the cutting tool. The faceted, coarse-grain surface (often >50µm) is vacuum-brazed to either the tungsten-carbide or HSS substrate.

Although strict control of the CVD process is critical, it is tool fabrication that ultimately determines edge quality and tool integrity. Most experienced fabricators use grinding wheels common to the PCD industry, but they extend the grind time in order to accommodate the increased hardness of the CVD-diamond material.

Tom Drury, general manager of J&M Diamond Tool, East Providence, R.I., said that his company uses wheels formulated for PCD to grind CVD diamond. It takes J&M toolmakers 10 to 20 percent longer to grind a CVD-diamond tool with an edge quality that is comparable to PCD tooling.

However, extending the grind time lets toolmakers attain an edge finish that is superior to PCD. Since CVD diamond is more erosion-resistant than PCD, though, simply increasing the feed rate of the grinding wheel can create excessive grinding forces that will damage the CVD-diamond cutting edge.

Thick-film CVD diamond can be used to create a brazed, mirror-finish (<0.05µm Ra) cutting tip with a finish-ground flank face. This unique combination enables thick-film tips to generate a superior workpiece finish, compared to a thin-film CVD-diamond coating. It also creates an opportunity for the replacement of single-crystal diamond tooling in selected applications.

The mechanical integrity and wear resistance of freestanding CVD-diamond material makes it an excellent choice for a wide range of machining applications, from woodworking to the milling of high-silicon aluminum. The tool life of CVD diamond when machining aluminum alloys is often one-and-a-half to five times that of commercial PCD grades. The actual improvement depends on the aluminum alloy, cutting tool design and fabrication techniques. But the high-productivity cutting speeds and feeds that are used to machine with PCD also apply to CVD diamond.

CVD-diamond tools commonly are used to turn pistons, make the interrupted cuts needed to finish-turn aluminum wheels and the general machining of other high-silicon-aluminum materials and metal-matrix composites.

Although high-silicon aluminum has always been the focus of CVD-diamond case studies, diamond-tipped tooling is becoming more popular in the machining of low-silicon aluminum, where high-productivity operations or stringent finish requirements dictate the use of diamond tooling.

Drury said that an automotive customer performed an aluminum-finishing operation in which CVD-diamond-tipped tools not only outlasted PCD by 30 percent, but also maintained the required surface finish throughout the life of the tool.

Tungsten carbide is precision-machined using a variety of materials, including single-crystal, PCD, PCBN (polycrystalline cubic boron nitride) and, more recently, CVD diamond. In one test, CVD diamond was used in a cylinder-boring operation. The tungsten-carbide (25 percent cobalt) cylinder had a 20mm inner diameter and 40mm length. It was machined using flood coolant with a speed of 30m/min., a feed of 0.05mm/rev. and a DOC of 0.12mm. The thick-film CVD-diamond tool machined eight parts before it failed. The PCD tool was able to machine five parts, and PCBN could only complete one part.

The natural purity of vapor-deposited diamond and advances in the manufacture and fabrication of freestanding CVD-diamond tools can provide a superior solution for many difficult-to-machine materials. And, as evidenced by its more recent successes in dressing and truing tools, CVD diamond is quickly gaining recognition as a material with the potential to enhance performance and productivity in an ever-broadening array of industrial materials and applications.

Diamond Dressing: The Next Generation

Dressing tools are generally used to remove dull ceramic or superabrasive grains from grinding wheel surfaces in an effort to repress grinding temperatures, improve workpiece finish and improve the grinding wheel's ability to hold tighter workpiece tolerances. They are also used for truing a grinding wheel.

Historically, most dressing and truing operations have been performed with stationary dressing products that are fed into a rotating wheel. These products are often made using single-crystal diamond or PCD.

Today, many high-productivity grinding operations employ rotary CNC dressers, or shaped dressing rolls, which can be used to continuously dress one side of a grinding wheel while the workpiece is being machined on the opposite side. CNC rotary dressers may contain over 100 similar pieces of diamond, which are handset on the outer diameter of the dresser and can be engineered to create unique forms in a grinding wheel.

Laser-cut, freestanding CVD diamond offers several unique advantages to users and manufacturers of dressing tools. The structure of the CVD diamond can be engineered to have enhanced fracture toughness and strength, thereby optimizing dressing tool life and dimensional stability.

And because CVD diamond is cut into uniform pieces, it can minimize, or even eliminate, the design challenges associated with single crystals. These include shape constraints and the variability that is inherent in natural diamond. Finally, CVD-diamond material can be constructed with high aspect ratios (e.g., 8mm x 1mm x 1mm) that can be cost-effectively incorporated into CVD-diamond dressing tools for longer life and better dressing efficiency.

—B. Cline

About the Author

Brian Cline was formerly an application manager with Saint-Gobain Industrial Ceramics Inc., parent company of Norton Diamond Film, Northboro, Mass. He is currently a consultant to the CVD-diamond cutting tool and wear-part industries.