Software

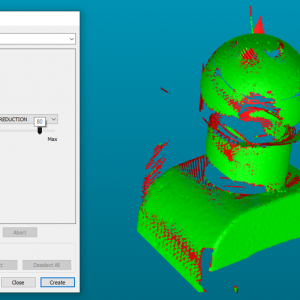

Drastically Cut Machining Costs with VERICUT Force

VERICUT Force is the standard for NC program optimization. Force optimization can reduce machining times up to 25 percent or more, produce better quality parts, and extend tool life up to 2X. Force can optimize any CAM or manually generated tool path, using any tool or material. Force balances both tool life and speed to match your machining goals. Force Charts expose opportunities for improvement and provide NC Programmers with valuable information to make data driven decisions to achieve optimal machining conditions.