Hypertherm at FABTECH 2024 – Plasma & Water Jet Cutting

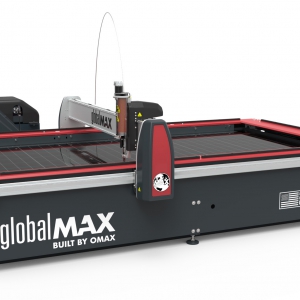

Jake Brown shares highlights from FABTECH 2024, where Hypertherm showcased its latest advancements in plasma and water jet cutting. The XPR 460 plasma system, now integrated by all OEMs, took center stage, along with the PowerMax, the industry’s top-selling handheld plasma cutter. Attendees also explored a two-headed water jet design for enhanced productivity and new software upgrades improving cutting speed and user experience.