October 2011

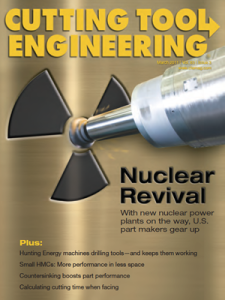

Manufacturers large and small develop strategies to quickly redesign and machine new parts for military customers. PLUS: Tools and techniques for engraving 2-D data matrix bar codes on machined metal parts Fine finishing with wire EDM is eliminating the need for secondary operations How microscopes and vision systems are used in machine shops for noncontact...