3D printing gets faster, by jellin’

3D printing gets faster, by jellin’

An issue slowing down 3D printing's advance into manufacturing is that the process itself is too slow to meet production requirements. Now, a collaboration between MIT, Steelcase and product designer Christophe Guberan presents a novel technique they call Rapid Liquid Printing, which can reduce the time of certain 3D printing applications from hours to minutes.

An issue slowing down 3D printing's advance into manufacturing is that the process itself is too slow to meet production requirements. Now, a collaboration between MIT, furniture maker Steelcase and product designer Christophe Guberan presents a novel technique they call Rapid Liquid Printing, which can reduce the time of certain 3D printing applications from hours to minutes.

Three dimensional printing traditionally requires a support structure, a layer-by-layer buildup, and a separate curing process in order to create objects. Those needs tend to lend themselves to a slow, small-scale and low-quality process. MIT's Self-Assembly Lab and its collaborators aimed to create a new process improving on speed, size and quality material.

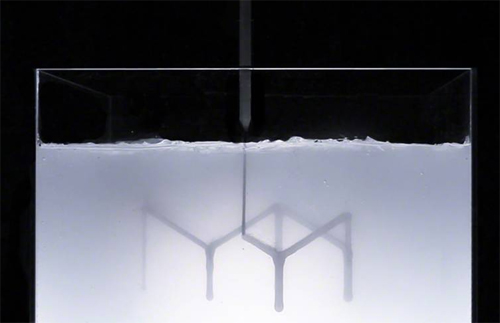

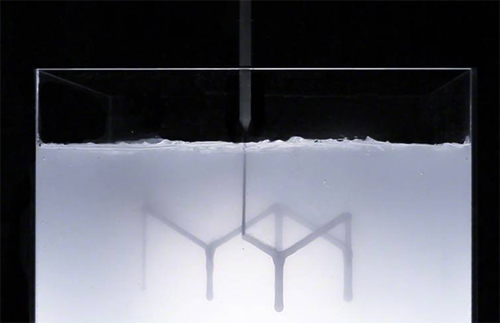

A Seelcase news release explains that the new process prints inside of a gel — essentially allowing a product designer to "draw" in 3D space without the limitations of gravity. Because there is no traditional support material and structure or layering, the printing process is much faster. The object's size is limited only by the size of the gel tank and the reach of the extrusion nozzle. A two-part mixing process allows the material to be chemically-cured instead of set using light or heat. The technique mixes, extrudes and cures all while the 3D printing is underway. And once the object is finished, the gel is rinsed away. In an experiment, an object that reportedly would have taken 50 hours to print using traditional methods was Rapid Liquid Printed in 10 minutes.

The collaborators are working on refining the technology, including improving the range of properties the prrinted material can have. Steelcase is interested in using the process to create custom furniture pieces--but its potential for use in manufacturing is obvious.

The Steelcase news release is here.