ATV and InnovationQuarter invest in Delft robotics startup IMSystems

ATV and InnovationQuarter invest in Delft robotics startup IMSystems

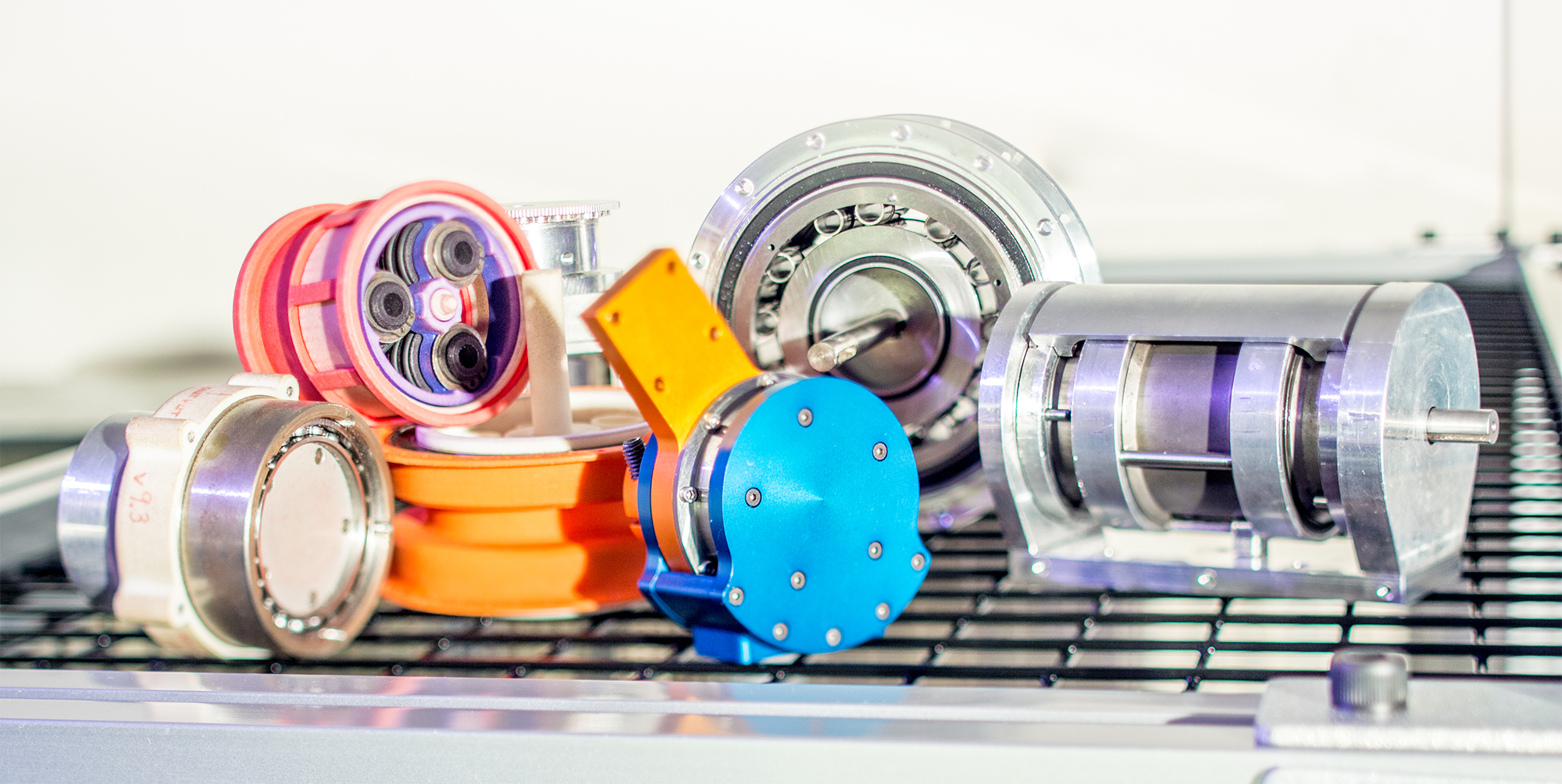

ATV and InnovationQuarter's investment in IMSystems will help further accelerate the development of their technology in robotics. IMSystems' Archimedes Drive takes a leap forward in transmission systems. In contrast to conventional gears, which rely on cogs with fragile teeth to produce torque, IMSystems came up with a design that harnesses traction.

ATV and InnovationQuarter's investment in IMSystems will help further accelerate the development of their robotics technology. IMSystems' Archimedes Drive takes a leap for-ward in transmission systems. In contrast to conventional gears, which rely on cogs with fragile teeth to produce torque, IMSystems came up with a design that harnesses traction.

ABB will be joining this round, through its venture capital unit, ATV, to provide funding and expertise to the growing company. The regional economic development agency for Zuid-Holland, InnovationQuarter, will continue its contribution in IMSystems following its initial seed investment in 2018.

"I am delighted to have next to InnovationQuarter ATV on board. The investment will allow IMSystems to grow and move to the next stage of development," said Jack Schorsch, CEO and founder of IMSystems. "The previous invest-ment round has shown that we were able to increase the lifetime of the drive from just a few minutes to a few weeks. With this round we will be able to go from weeks to years, and prepare the Archimedes Drive for commercial use to enable lighter, more agile, and more accurate robots."

It was in 2016 when PhD student, Jack Schorsch, grew frustrated with the inadequacy of off-the-shelf transmission systems available for the robot he was designing at Delft University of Technology. This frustration led him to his idea for a stronger, lighter, more accurate alternative: the Archimedes Drive, a design that harnessed traction. This innovation reportedly meant the first breakthrough in transmission systems since 60 years.

IMSystems' patented Archimedes Drive marks a leap forward in robot transmission systems. Automated production lines are becoming more commonplace in most manufacturers, but the broader deployment of industrial robots is hampered by existing mechanical components, namely the transmissions.

The gears that enable robotic arms to swing, pick, lift and place are bulky, heavy and the cause of backlash. (This is an undesirable staccato jolt caused by the small clearance between the teeth in conventional gears.) These limitations in accuracy have an impact on safety, which means that industrial robots are usually consigned to cages. It's also one of the reasons why it's a human rather than a robot that manufactures smartphones, and also why surgical robots are the exception rather than the rule. The Archimedes Drive therefore paves the way for operations without a surgeon pre-sent and for co-operation between humans and robots, so-called "cobots."

IMSystems' Archimedes Drive is a product of the Dutch province Zuid-Holland's entrepreneur-centric network that fosters innovation. The Drive was invented at Delft University of Technology, commercialized at startup incubator Yes!Delft, and is now being developed for the international robotics market at RoboValley," said Rinke Zonneveld, director of InnovationQuarter. "We are proud to be working with Jack and his team in realizing their goal of smaller, lighter, and more accurate industrial robotics."