Cross hole deburring made easy with CNC equipment

Cross hole deburring made easy with CNC equipment

In the past decade, a California-based machine shop has relied on a flexible, honing tool for a range of automated CNC machining applications such as cross hole deburring, cylindrical honing, surface finishing, edge-blending and cleaning.

The Delta Machine Co. is a machine shop that specializes in complex, tight tolerance parts made of titanium, nickel alloys, stainless steel, aluminum, plastics and other exotic alloys.

The Delta Machine Co. is a machine shop that specializes in complex, tight tolerance parts made of titanium, nickel alloys, stainless steel, aluminum, plastics and other exotic alloys.

Janos Garaczi, president of the Huntington Beach, California, company, is responsible for overall quality as well as much of the programming, set-ups and purchasing.

In the past decade, the machine shop has relied on a flexible, honing tool for a range of automated CNC machining applications such as cross hole deburring, cylindrical honing, surface finishing, edge-blending and cleaning.

By integrating flexible hones in the machining process, complex parts with cross-drilled holes and other difficult-to-access features can be deburred, honed, and surface finished, in-house, at less cost.

In automated machining, removal of burrs and sharp edges in cross-drilled holes and other difficult-to-access areas such as undercuts, grooves, slots, or internal holes can be tedious and time consuming. One particular challenge is deburring the intersection of cross-drilled holes frequently found in engine and transmission components.

In many applications, cross-drilled holes act as conduits for fluids, lubricants and gases and failure to remove burrs can cause blockage of these critical passages or create turbulence in the flow. Burrs can also lead to part misalignments, affect dimensional tolerances, and limit the overall efficiency of machined components.

"Eliminating burrs is critical because if any loose material gets dislodged during use, there can be serious consequences," said Garaczi.

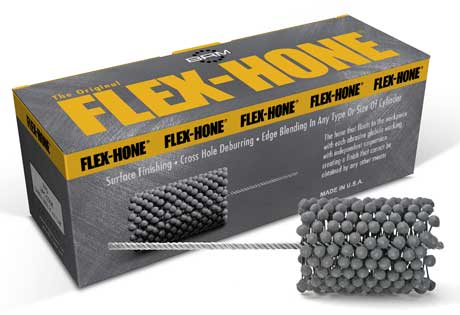

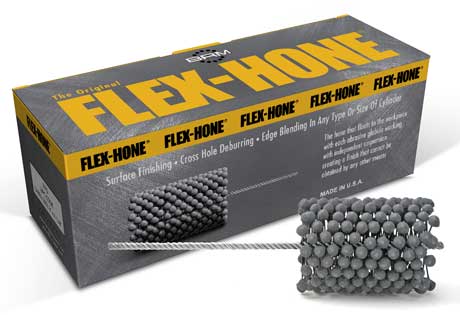

According to Garaczi, the tool he selected for such applications is the Flex-Hone from Los Angeles-based Brush Research Manufacturing (BRM). Characterized by the small, abrasive globules that are permanently mounted to flexible filaments, the product is a flexible, low-cost tool utilized for sophisticated cross hole deburring, honing, surfacing, and edge-blending. The hones are available in a variety of abrasive types, sizes, and grit selections.

"For de-burring holes and honing when we need to clean up a component, it is the easiest tool to use for us. There is a large variety of grades and sizes and it is very versatile," says Garaczi,

He added that the company is "making more complex parts, especially when it comes to housings with ports all over the part. That is where the hone comes in really handy – for de-burring the holes where you drill into it."

For best results, the deburring tool is typically rotated into the main bore into which the cross holes break. After a few clockwise strokes, the tool is removed and the spindle reversed to rotate and stroke the flexible hone in a counterclockwise direction for a few more strokes. The forward and reverse rotation creates a symmetrical deburring pattern. Coolant should be used to keep metal cuttings and deburred metal in suspension.

According to Garaczi, removing burrs can be particularly problematic when dealing with machined superalloys, such as titanium, Monel, Inconel, Incoloy, Invar, Rene and Hasteloy.

"Even during 'grooving,' if you cut the material from one side, it just pushes the burr to the edge," said Garaczi. "And, if you approach it from the other side, it just pushes it back. It doesn't want to break off the material cleanly. As soon as the tool gets a bit dull it gets a lot worse. So, sharp tools with the right geometry are key."

Garaczi notes that the Flex-Hone is available with a premium nickel coated diamond abrasive for use on materials like carbide, ceramic and aerospace steel alloys; as well as a CBN option that is even harder and is specifically designed for superalloys. These superalloys can exhibit high ductility and work hardening that produce a gummy machining behavior if the correct abrasive tool is not utilized. He added that Flex-Hone helps deburr superalloys such as titanium or heat treated 13-8 stainless alloy.

Garaczi points out that he is installing the flexible hones into CNC equipment to automate the process and reduce the time required to finish superalloys and stainless steels.

Another advantage of Flex-Hone is that it doesn't create much dust, important considering the damage contaminants might cause to the CNC equipment. "These are very expensive, very accurate machines," adds Garaczi. "I wouldn't do anything to jeopardize the accuracy or lifespan of the equipment."

He says that when making decisions about what tools to purchase it is often on a project-by-project basis. However, if the tool can reduce cycle times versus its cost, it is an easy decision.

"There are definitely scenarios where it would be good to be able to perform surface finishing of this type of material on CNCs," says Garaczi. "It would really save a lot of time and extra processing cost ... I want to do everything on the CNC machines whenever I can."

To achieve this, the machine shop incorporates Flex-Hones in a variety of sizes in its tool carousels.

"For a part, we might use two to three different size hones, depending on the number of cross port intersections and different hole sizes," says Garaczi. "However, it is really easy to put a Flex-Hone in a toolholder, give it a simple toolpath cycle and let it run."

For more information on Flex-Hone, phone 323-261-2193 or visit the web site at www.brushresearch.com.