Entrepreneurs crowdfund machine launches

Entrepreneurs crowdfund machine launches

Have a great idea for a machine tool but lack the cash to fund its commercialization? Crowdfund it! That's what Matthew Hertel did when he leveraged a Kickstarter campaign to raise more than $355,000 for the development and creation of his Pocket NC 5-axis milling machine. And then there's the WAZER, the world's first desktop waterjet cutter, which runs $4,499 on Kickstarter, and is expected to be affordable to hobbyists and small businesses.

Have a great idea for a machine tool but lack the cash to fund its commercialization? Crowdfund it!

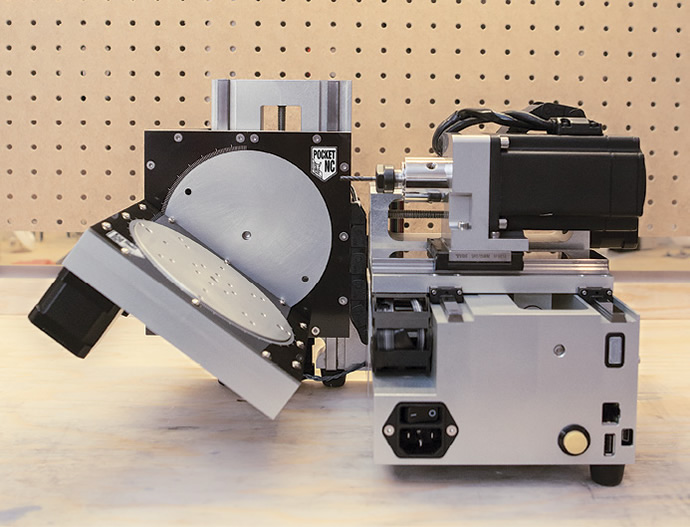

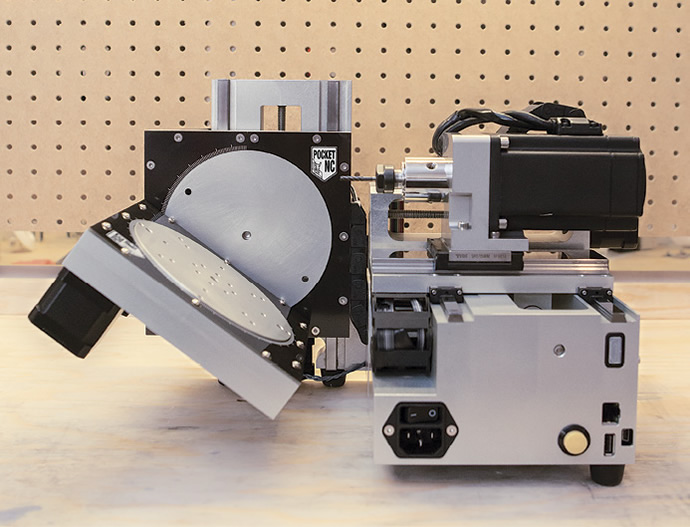

That's what Matthew Hertel did when he leveraged a Kickstarter campaign to raise more than $355,000 for the development and creation of his Pocket NC 5-axis milling machine. Since the first shipment in December 2015, Hertel and wife, Michelle, who's a mechanical engineer, have delivered more than 250 machines. Their company is Pocket NC Co., Great Falls, Mo. For more information, visit www.pocketnc.com.

Pocket NC has shipped more than 250 of its compact, 5-axis milling machines in the last year, after successfully completing a Kickstarter campaign. Image courtesy Pocket NC.

As its name implies, the Pocket NC fits on a desktop or workbench. The $4,000 machine features a Linux-based CNC and is programmed with Autodesk's Fusion360 CAD/CAM software. It also has a unique tilting-rotating table and horizontal spindle design that Hertel takes only partial credit for. "It took a lot of years and collaboration between several people to perfect," he said.

For the Kickstarter campaign, Hertel team members set their sights on a limited funding target and a manageable number of machines, a different approach than that taken by some in the crowdfunding community.

"Some folks go for the maximum amount possible, but we were concerned that manufacturing might take longer than anticipated," Hertel said. "Because of that, we were able to deliver all 100 of the initial machine orders on-time and have been going strong ever since. We've even sold machines to MIT and several other universities."

Two people nearing the finish line of their Kickstarter campaign are Nisan Lerea and Matt Nowicki, co-founders of WAZER Inc. Co-located in New York and Shenzhen, China, the company raised more than $1.4 million from more than 1,200 backers—and counting. The first machines are expected to ship in August 2017.

So far, WAZER has raised more than $1.4 million in a Kickstarter campaign to launch its waterjet cutting machine. Image courtesy WAZER.

What's a WAZER? According to Lerea, the WAZER is the world's first desktop waterjet cutter, a machine that cuts through virtually any material and, at $4,499 on Kickstarter, will be affordable to hobbyists and small businesses. For more information, visit goo.gl/Bc6HQO.

"We spent the majority of last year at the HAX Accelerator facility in Shenzhen (an investment company that supports entrepreneurs), where we worked with suppliers and finished up the design work," Lerea said. "HAX offered us a great opportunity to learn about the incredible manufacturing ecosystem in China. We were surrounded by 15 other hardware startups and were able to really develop the business. We're very excited about the way things are going."