Based in Bendigo, Victoria, The Edge Equine is an Australian manufacturer of equine dental products, primarily rasps for manual horse dentistry.

The company also provides commercial industrial sharpening services for the central Victorian region – specializing in high-precision sharpening such as broach drills, annular cutters, saw blades, and router bits for local commercial cabinet makers, sawmills, and food processors.

The company’s focus on manufacturing equine dental products stemmed from a local horse dentist’s request to sharpen his equine dental blades. Today, it is a point of differentiation as The Edge Equine has concentrated on a more traditional product while other manufacturers have moved to the electronics industry.

The Edge Equine pride itself on providing prompt service, made possible with on-site manufacturing capabilities that enable them to ship products within 48 hours. The company sells directly to over 40 countries, with distributors in the US, UK, New Zealand, and South Africa.

Tim McMahon, managing director of The Edge Equine said, “Our relationship with ANCA started in 2005 when we purchased a second-hand TG4. Over the years we grew to have three TG4s on the floor.

ANCA were fantastic, they helped us write our programs, get the machines up and going, and then when we swapped to our first FX3, ANCA developed the programs to make our products which were absolutely fantastic.”

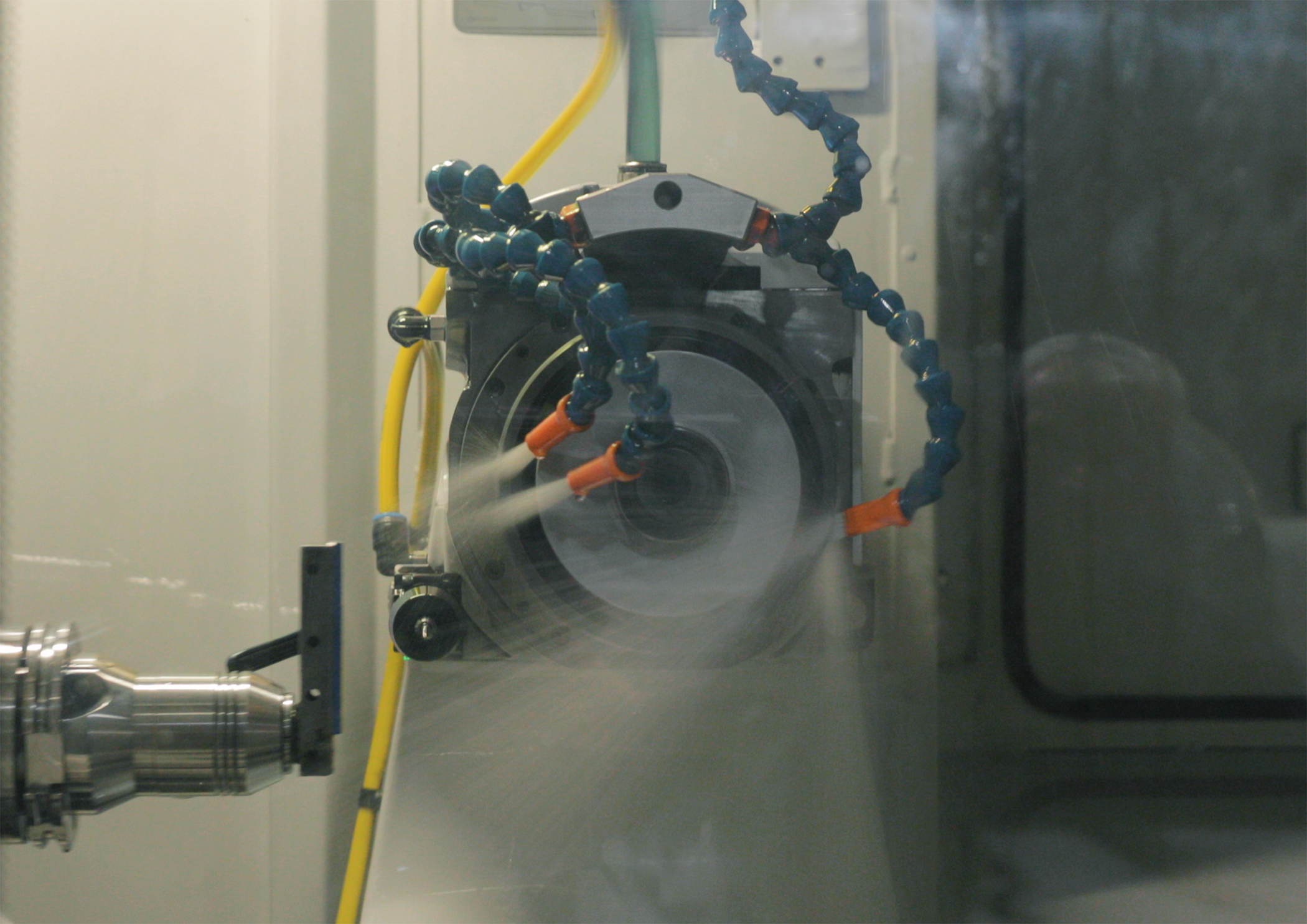

“We invested in the FX5E in 2020. We were after another machine, as our demand for product had grown to the point where the FX3 and the remaining TG4 couldn't cope. Jake [Farragher], ANCA Asia-Pacific General Manager recommended the new FX5E as having some features that would certainly help us grow, part of that being its future ability to be automated as our growth continued. It's been a pretty seamless transition with having the FX3 and FX5E on the floor.”

The Edge Equine mainly produces dental rasps and floats, devices that are used for the maintenance of horses’ teeth. “The average cycle time is approximately 14 to 16 minutes depending on the rasp profile that we're grinding which is two blades per cycle so it’s roughly eight minutes, seven to eight minutes per blade,” McMahon said. “Most of our clients around the world order on an as needs basis so prompt manufacture and supply is important to us and our customers.”

The future is bright with ANCA FX5E

McMahon said, “With the implementation of the FX5E, it has given us new scope to look at more high precision grinding in the industrial regrinding market. We do a lot of granular cutters, annular cutters, and broach cutters. We're also looking at new products once again in the veterinary space. These are sectioning burrs for basically cutting out teeth that are inside the horse's head. As you can see, they're quite a long burr. So there's a lot of growth in using the capabilities of the FX5E.”

“The FX5E has the capacity to have robotics fitted and it will be something to look at in the future as our market grows and with the help of ANCA, we'll develop a process to automate the process of blades. At the moment, we manually feed the machines, which still works well for us, but we have the opportunity to grow further on the automation stage.”

“The other major benefit of the FX5E is its flexibility. It gives us the capacity to change from manufacturing our rasps through to grinding tools within a matter of minutes. As with the FX3, we do jig setups, change things over, and change wheels. It becomes time-consuming. But the flexibility we have now is outstanding, we can go from one job to the next without losing any time.”

“The FX5E is probably the first opportunity where we've had the capacity and the wherefore to branch out into different products and it's also given us a lot more flexibility of sharpening our mills within our processing.”

McMahon recognizes that the company’s two-hour location from the ANCA headquarters is a major advantage. “Whenever we've had issues, there's always someone on the phone to talk to and usually they'll have a technician up here within 5 hours or the next morning. As our customers expect customer service from us, our expectation from ANCA is to have a high level of customer service – and they certainly provide.”

McMahon is confident that the company will see continual growth in the animal health industry, enabling The Edge Equine to be a leader in the manufacture of manual tools for equine dentistry. He envisions using the FX5E along with ANCA’s technology to manufacture other products within the veterinary space in the next 10 to 15 years.

“Prior to COVID, we would do three or four conferences a year within the USA, at least one in the UK, and Germany. We are and we'll always be looking at what the world needs and what the industry needs as far as these types of tools,” McMahon concluded.

Contact Details

Related Glossary Terms

- broach

broach

Tapered tool, with a series of teeth of increasing length, that is pushed or pulled into a workpiece, successively removing small amounts of metal to enlarge a hole, slot or other opening to final size.

- burr

burr

Stringy portions of material formed on workpiece edges during machining. Often sharp. Can be removed with hand files, abrasive wheels or belts, wire wheels, abrasive-fiber brushes, waterjet equipment or other methods.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- jig

jig

Tooling usually considered to be a stationary apparatus. A jig assists in the assembly or manufacture of a part or device. It holds the workpiece while guiding the cutting tool with a bushing. A jig used in subassembly or final assembly might provide assembly aids such as alignments and adjustments. See fixture.

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).