Mastercam 2022 drives machining center at Westec

Mastercam 2022 drives machining center at Westec

Customer and industry input drives development from faster 2D to expanded multiaxis.

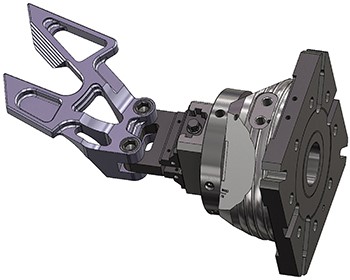

The latest version of Mastercam machining software will be on display at the Westec show located in Long Beach, California. There, from Nov. 16-18, the software will power a DMG MORI NLX 2500 machining center.

The latest version of Mastercam machining software will be on display at the Westec show located in Long Beach, California. There, from Nov. 16-18, the software will power a DMG MORI NLX 2500 machining center.

The new Mastercam 2022 package has features and enhancements that streamline the entire production process, from job setup to job completion, the company says.

Many of the advancements in Mastercam 2022 are directly driven by Mastercam users and shops. Feedback from Public Beta releases, shop visits, customer surveys, and consultation with our expert industry partners create the practical, shop-driven focus that helps ensure Mastercam users' success, said Meghan West, Mastercam president and CEO.

"Mastercam is developed by listening to our users and creating solutions for their problems," she said. "We adapt to changing needs to ensure that the customer experience is the best it can be as we continue to innovate for improved automation, efficiency, connectivity, and precision."

Features of the new software package, include:

OptiRough toolpath for 2D users. The 3D High Speed Dynamic OptiRough toolpath is now available for all Mill and Router product levels. This allows users to machine large cut depths with a bidirectional cutting strategy to remove the maximum amount of material with the minimum number of stepdowns. Dynamic OptiRough allows users to create a single toolpath to machine a part, instead of creating multiple 2D operations to achieve the same goal. The toolpath is collision aware of the part, and for complex machining, the toolpath can also be aware of the tool holder.

Multiaxis programming. As more shops seek the benefits of a single setup, multiaxis cutting strategy, Mastercam 2022 adds new techniques and strategies such as the Unified Multiaxis toolpath that selects multiple pieces of input geometry to generate the toolpath pattern. Using those geometry choices, the toolpath picks the best algorithm to calculate the path. Multi-pass on Deburr toolpaths supports flat chamfered and rounded edges that gives the user added flexibility, allowing the Deburr toolpath to create a quality surface finish on larger chamfered or radiused edges.

Modeling advances. Mastercam 2022 introduces powerful mesh creation and editing capabilities that deliver a new class of modeling tools, including the ability to reconstruct models from scanned data. Being able to directly edit wireframe geometry without interacting with the dialog box speeds up design and modification work. And, the Overflow UV function allows users to replace multiple surfaces with inconsistent flows with a single surface for flowline toolpaths. Users can also simplify surfaces for general modeling. Overflow UV generates a single unified surface with a desired UV flow on a connected set of surfaces.

Enhanced intelligence and automation. A suite of system-wide enhancements helps automate tasks and speed your workflow. New automatic region chaining uses a "smart" approach to auto-select logical chained areas. Holemaking from imported solids is faster as Mastercam will now automatically extract appropriate information and pre-populate your programming options. Even tool imports have been made more intelligent as Mastercam will infer more tool properties from an incoming tool CAD model.

To see more of the Mastercam 2022 tools, stop by booth #1303 at Westec or visit www.mastercam.com or https://whatsnew.mastercam.com.