Mobile robot automation powered by intelligent robotic solutions

Mobile robot automation powered by intelligent robotic solutions

Automation tasks are becoming more challenging. However, using intelligent software in combination with the relevant automation solutions not only enables workpieces to be loaded and unloaded but also means that machine tools can be set up fully automatically through the automatic replacement of tools and clamping devices.

By WFL Millturn Technologies

Automation tasks are becoming more challenging. However, using intelligent software in combination with the relevant automation solutions not only enables workpieces to be automatically loaded and unloaded but also means that machine tools can be set up fully automatically through the automatic replacement of tools and clamping devices.

FRAI Robotic Technologies is a company that helps to solve automation challenges. It strives to be an innovative automation partner and is therefore developing highly flexible robot systems to respond to this trend. Concepts such as the mobileCELL enable a wide range of expansion stages, making them as future-proof and competitive as possible.

Flexible at all levels

Different industries, series production, small batch sizes, a variety of machine tools and the uncertainty of many manufacturers as to whether the current product will still be in vogue next year or become a slow seller -- all this calls for flexibility in production.

For automation, this means keeping pace with increasing demands. The systems must produce autonomously around the clock, be flexible to use, and be Industry 4.0 compliant. In addition to the classic changeover of parts, automation also takes on other tasks such as tool change, parts transport, logistics, host computer functions, part tracking and product history.

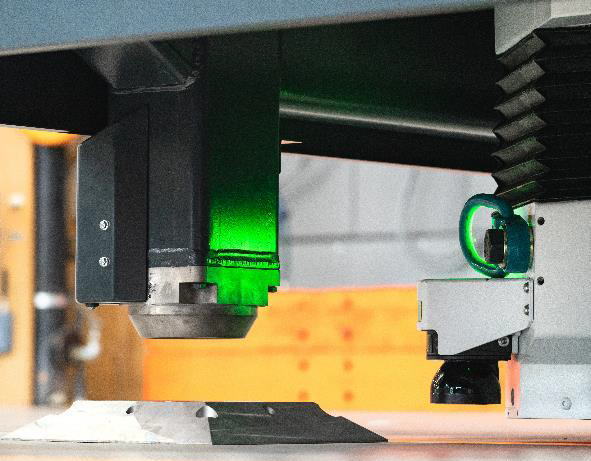

The more complex the task, the more elements are needed from what the company calls a "know-how kit." The know-how kit is what FRAI calls the solutions that have already been successfully implemented in practice and work under real production conditions. FRAI has already developed a large number of kit elements: parts and position recognition, bin picking, reading and inscribing a DMC (Data Matrix Code), parts contour monitoring, automatic gripper exchange, and jaw changes.

Depending on the task in question, FRAI also has a network of partner companies that cover other aspects such as host computer solutions. Multitasking in production Several mega and macro trends will shape not only automation, but also virtually all industrial sectors in the coming years.

First, there is individualization: there will be smaller series and more frequent product changes and innovations. Second, there are connectivity needs: everything is networked, and each component has a QR code and can be tracked through to recycling.

If you think about a smartphone, making a phone call is no longer the key function. The same is true of automation, in the sense that transporting a workpiece from A to B is not necessarily the main task in every application. Instead, the focus has shifted toward recognition, tracking and multitasking. Camera recognition and gripper exchange systems combined with host computer solutions have become the core components of a flexible solution that is compatible with Industry 4.0. Globally, the trend will move towards a small-cell solution with high intelligence and a high proportion of IT.

These trends and requirements call for overall networking, in particular information data acquisition and evaluation.

This is becoming increasingly important. Manufacturers need to be able to acquire, process, evaluate or pass data on. This allows for optimized production, the sequence and subsequently the capacity utilization, and also to meet customer requirements, which call for 100% traceability and parts history.

Improving capacity utilization lowers unit costs, while higher quality lowers the cost of poor quality. These are well-known requirements, however, they are becoming increasingly important. So, in the future, automation will be about using corresponding hardware to ensure a flexible material flow, handle components and also implement a variety of set-up processes.

Automation as an overall package

When it comes to modern automation concepts, holistic customer support starts with the technical sales team. Here, experienced technicians must work hand in hand with visionaries, 3D designers and software specialists to create the most useful overall concept for the customer. These resources must be provided at both the quotation stage and also later on for order processing.

This requires training young people and ensuring a good mix in all departments so the company is prepared for the new tasks.

Mobile robot solution

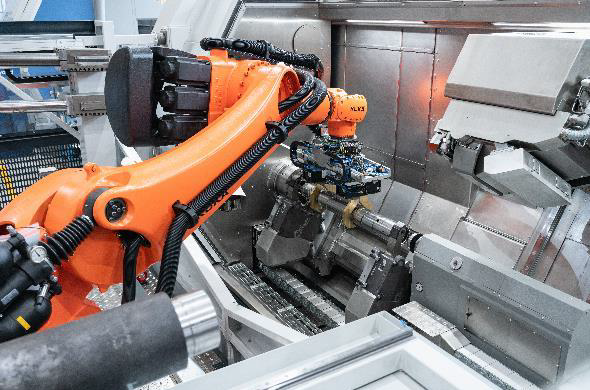

The mobileCELL of FRAI is a hybrid solution, which combines wide-ranging functions and advantages. There was a time when the classic robot cell could only load and unload workpieces. This basic function was then enhanced with gripper exchange systems.

Due to the significant disadvantages of a location-bound robot cell and the costs for intralogistics tasks, a solution was discussed which would produce advantages for the customer. This is how the concept of the mobile robot matured and was converted into a prototype.

A generously-sized automated guided vehicle (AGV) features a robot cell design with everything that is needed. In other words, the AGV should include the robot, workpiece and tool gripper, along with buffer positions for workpieces and tools, and the necessary control & safety technology.

The machine is freely accessible. It is not blocked or obstructed. The AGV collects the required tools and workpieces in the warehouse, it then travels to the front of the machine, locks itself in place on the floor and exchanges parts or tools. The vehicle then moves away again and receives the travel instructions for the next machine. The space in front of the machine it has just loaded becomes clear again.

For a mobileCELL to be useful, there has to be a long enough cycle time or there must be other advantages such as flexible, internal transport with the use of several mobile robots. The travel paths must be suitably wide (3m); that is usually the case for normal forklift operations. The wheels are designed to travel over expansion joints and slots, such as we might have with fire doors or similar, without any problems. A virtual server and a WLAN network must be available, but that is also the industry standard these days.

Advantages offered by mobileCELL

- Space saving in front of each machine that is being served

- Optimum access to the machine for operators and service personnel

- One robot can be used for several machines

- Interlinked machines and processes do not have to be in a line or next to one another

- The storage area is in the low-cost warehouse space, not in the expensive production hall

- Tools can be used universally on several machines, they are not locally tied to individual machines

- Intralogistics costs are reduced, as the AGV takes the parts to the next process or the warehouse

- Compatibility with machines that could not otherwise be automated or for which a separate robot cell would not be possible