The sound of hybrid machining is heard at FABTECH

The sound of hybrid machining is heard at FABTECH

As part of the newly created 3D/Additive Manufacturing Pavilion at the FABTECH 2017 trade show held Nov. 6-9 at Chicago's McCormick Place, Fabrisonic LLC's exhibit showcased the company's hybrid ultrasonic additive manufacturing (UAM) and subtractive machining capabilities.

As part of the newly created 3D/Additive Manufacturing Pavilion at the FABTECH 2017 trade show held Nov. 6-9 at Chicago's McCormick Place, Fabrisonic LLC's exhibit showcased the company's hybrid ultrasonic additive manufacturing (UAM) and subtractive machining capabilities.

The solid-state nature of the ultrasonic bonding process used in UAM permits joining layers of dissimilar metals without the formation of brittle intermetallics as seen in fusion processes, the company reports. A host of material combinations have been successfully merged via ultrasonics, including aluminum and titanium, nickel and stainless steel, and silver and gold.

Click here to discover how the technology works.

In addition, copper is often combined with aluminum, with copper employed for its wicking capabilities and aluminum for its weight-reduction benefits, noted Mark Norfolk, president and CEO of the Columbus, Ohio, company.

"It's a true solid-state weld," he said, adding that electron sharing occurs between the molecules of each metal layer.

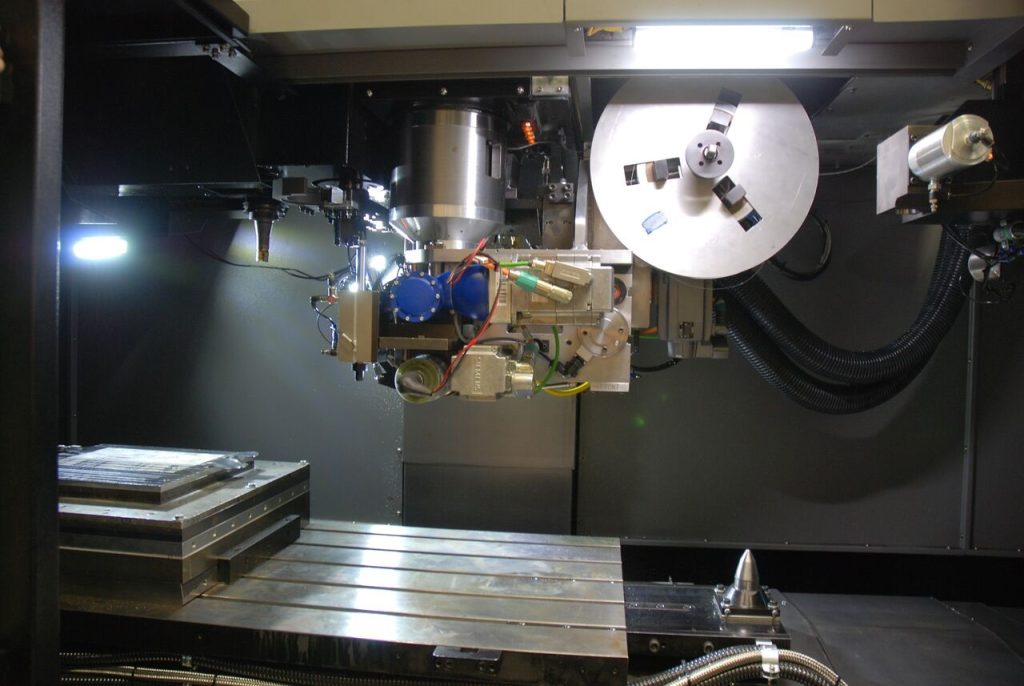

With the UAM welding head positioned in a CNC machine tool's toolchanger/" data-glossary-id="142091" data-glossary-teaser="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" title="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" aria-label="Glossary: toolchanger/" data-glossary-id="142091" data-glossary-teaser="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" title="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" aria-label="Glossary: automatic toolchanger">automatic toolchanger">automatic toolchanger, the welding process can be stopped at any point and 3D channels and other part features can be machined, the company states. Subsequently, the additive process continues to build up metal, sealing in complex 3D flow paths.

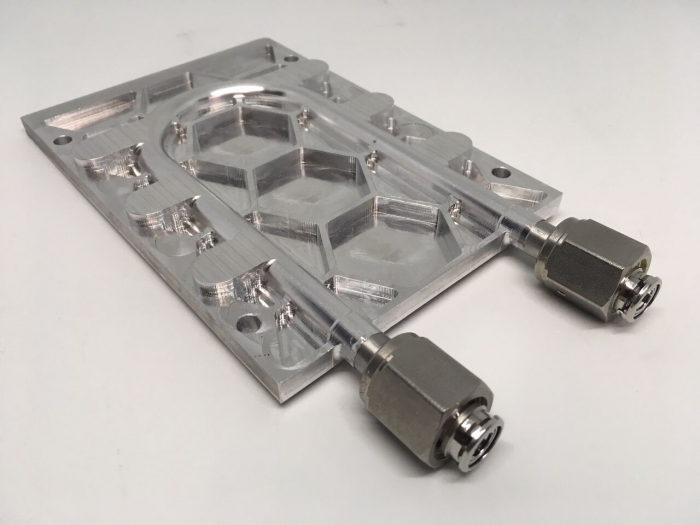

Norfolk said manufacturing heat exchangers is a "huge" market for the hybrid technology because it avoids brazing multiple components together. Aluminum heat exchangers have been produced with burst pressures of more than 6,000 psi (414 bar).

UAM allows printing complex internal flow passages, such as in this 3D-printed heat exchanger. Multiple metals can be printed in the same build. For instance, copper can be printed in strategic locations to help spread heat evenly across the radiating surface. Courtesy: Fabrisonic

The manufacturing process can start with a layer of metal as thin as 0.005" (0.127mm) or a billet as thick as 3" (76.2mm) when an application doesn't require printing to that dimension, Norfolk said. "3D printing is slow and expensive."

Fabrisonic sells hybrid machines, can retrofit the welding head into a suitably rigid machine, such as a CAT 50 one, and performs contract manufacturing with its four in-house machines.