United Grinding North America Inc. wins award

United Grinding North America Inc. wins award

MIAMISBURG, Ohio – UNITED GRINDING North America earned recognition for the outstanding growth of its sales of FANUC robotic systems at the 20th annual FANUC Authorized Systems Integrators (ASI) Meeting.

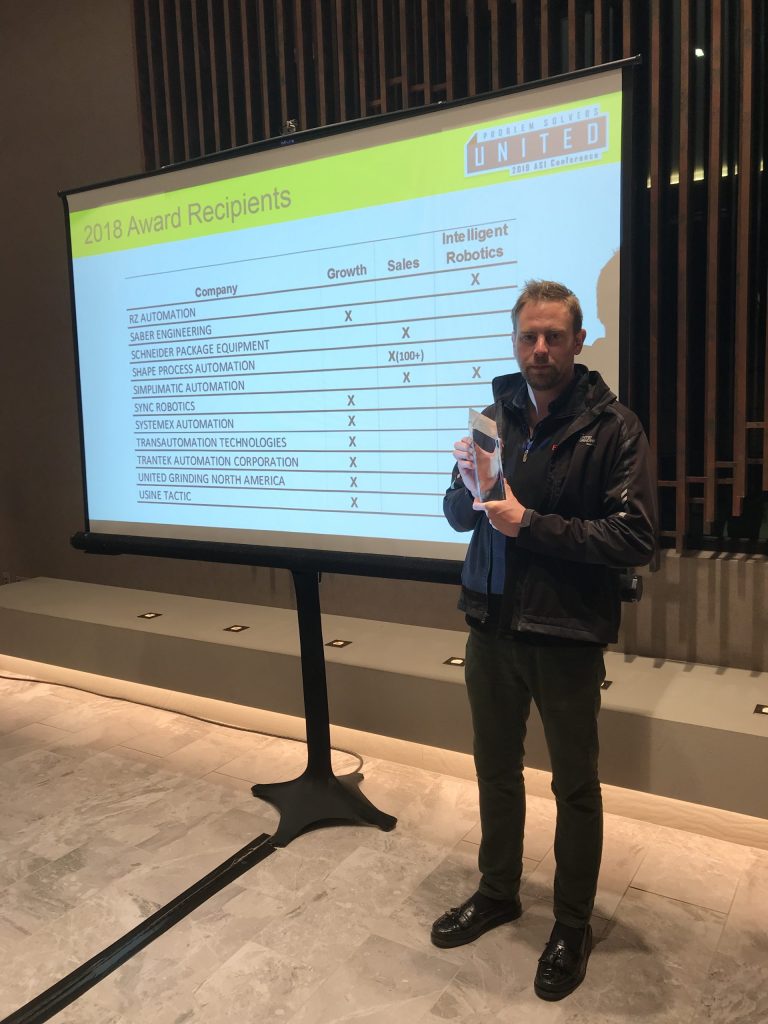

MIAMISBURG, Ohio – UNITED GRINDING North America earned recognition for the outstanding growth of its sales of FANUC robotic systems at the 20th annual FANUC Authorized Systems Integrators (ASI) Meeting. The awards ceremony, which took place in Scottsdale, Arizona, on February 12, 2019, honored distributors and manufacturers alike who, like UNITED GRINDING North America's Automation Solutions Department, helped customers achieve improved productivity and higher throughput with innovative automated systems.

"We were thrilled to be recognized for our efforts in growing FANUC sales," said Simon Bramhall, general manager of UNITED GRINDING North America Automation Solutions. "Whether it's the flexLoad standard automation system or one of the custom solutions we've helped develop for customers, we've strived to serve as the single-source provider of automated systems for our grinding technology – a mission made possible by our partnership with FANUC."

The FANUC ASI Meeting brings together automation integration leaders from across the manufacturing industry for annual reports and continuing education opportunities from FANUC America. Topics of discussion this year include an overview of the automation industry, introductions to new FANUC product features, approaches to financing capital purchases and a panel discussion about educating the next generation of manufacturing professionals, among many others. The event also included the annual Innovative System of the Year contest, which recognizes outstanding integrators from across the country.