U.S. robot installations exceed pre-pandemic level

U.S. robot installations exceed pre-pandemic level

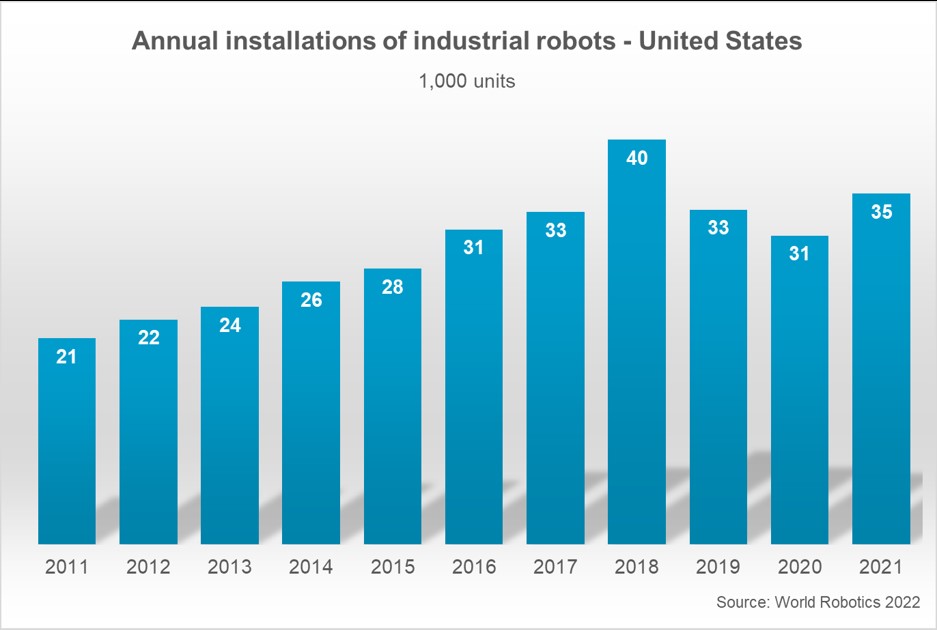

The World Robotics Report shows that robot installations in the United States were up by 14% to 34,987 units in 2021 -- the second most successful year for the robotics industry in the U.S.

The World Robotics Report shows that robot installations in the United States were up by 14% to 34,987 units in 2021 -- the second most successful year for the robotics industry in the U.S.

This exceeded the pre-pandemic level of 33,378 units in 2019.

"The use of robotics and automation is growing at a breathtaking speed," says Marina Bill, President of the International Federation of Robotics. "Within six years, annual robot installations in factories around the world more than doubled. According to our latest statistics, installations grew strongly in 2021, although supply chain disruptions as well as different local or regional headwinds hampered production."

United States

The automotive industry installed 9,782 industrial robots in the United States in 2021.

The US accounted for 64% of the North American installations in the automotive industry in 2021. However, this share used to exceed the 70% mark in previous years.

Installations in the US automotive industry declined by another 7% in 2021, while installations in the Mexican and Canadian automotive industries increased by 92% and 72% respectively.

The metal and machinery industry in the U.S. surged by 66% to 3,814 units in 2021, putting this industry in second place in terms of robot demand.

The plastic and chemical products industry had 3,466 robots (+30%) newly installed in 2021.

Outlook

Despite several global and regional challenges, the overall expectation for the robotics market in the United States and North America is positive. Order intake is very high.

Robot installations are expected to grow by +15% in 2022 as scarcities turn into sales orders. Assuming that these scarcities will be reduced, the backlog of orders offers the potential for even higher growth rates in 2023.

Around the rest of the world, robot installations were also increasing.

Worldview

The new World Robotics report shows an all-time high of 517,385 new industrial robots installed in 2021 in factories around the world. This represents a growth rate of 31% year-on-year and exceeds the pre-pandemic record of robot installation in 2018 by 22%. Today, the stock of operational robots around the globe hits a new record of about 3.5 million units.

"The use of robotics and automation is growing at a breathtaking speed," says Marina Bill, President of the International Federation of Robotics. "Within six years, annual robot installations more than doubled. According to our latest statistics, installations grew strongly in 2021 in all major customer industries, although supply chain disruptions, as well as different local or regional headwinds, hampered production."

Asia and Europe--overview

Asia remains the world's largest market for industrial robots. 74% of all newly deployed robots in 2021 were installed in Asia (2020: 70%).

Installations for the region´s largest adopter China grew strongly by 51% with 268,195 units shipped. Every other robot installed globally in 2021 was deployed here. The operational stock broke the 1-million-unit mark (+27%). This high growth rate indicates the rapid speed of robotization in China.

Japan remained second to China as the largest market for industrial robots. Installations were up 22% in 2021 with 47,182 units. Japan's operational stock was 393,326 units (+5%) in 2021.

After two years of declining robot installations in all major industries, numbers began growing again in 2021. Japan is the world´s predominant robot manufacturing country: Exports of Japanese industrial robots achieved a new peak level of 186,102 units in 2021.

The Republic of Korea was the fourth largest robot market in terms of annual installations, following the US, Japan and China. Robot installations increased by 2% to 31,083 units in 2021. This followed four years of declining installation figures. The operational stock of robots was computed at 366,227 units (+7%).

Europe

Robot installations in Europe were up 24% to 84,302 units in 2021. This represents a new peak. Demand from the automotive industry was steady, while demand from the general industry was up by 51%. Germany, which belongs to the five major robot markets in the world, had a share of 28% of total installations in Europe. Italy followed with 17% and France with 7%.

Germany's number of installed robots grew by 6% to 23,777 units in 2021. This is the second-highest installation count ever recorded, following the peak caused by massive investments from the automotive industry in 2018 (26,723 units). The operational stock of robots was calculated at 245,908 units (+7%) in 2021. Exports of industrial robots from Germany were up 41% to 22,870 units, exceeding the pre-pandemic level.

Italy is the second largest robot market in Europe after Germany. The main growth driver between 2016 and 2021 was the general industry with an annual average growth rate of 8%.

The operational stock of robots was computed at 89,330 units (+14%) in 2021. The 2021 results were driven by catch-up effects and earlier purchases due to a reduction of tax credits in 2022. This created a 65% increase in robot installations to a new record level of 14,083 units in 2021.

The robot market in France ranked third in Europe in 2021 regarding annual installations and operational stock, following Italy and Germany. In 2021, robot installations increased by 11% to 5,945 units. The operational stock of robots in France was calculated at 49,312 units, a 10% increase over the previous year.

In the United Kingdom, industrial robot installations were down by 7% to 2,054 units. The operational stock of robots was calculated at 24,445 units (+6%) in 2021. This is less than a tenth of Germany´s stock. The automotive industry reduced installations by 42% to 507 units in 2021.