Industry News

06/30/2014

Look for a special digital supplement to the August 2014 issue of Cutting Tool Engineering (CTE) magazine in your email inbox next month. The special digital edition, sponsored by Makino Inc., will feature the results of our biennial salary survey, a variety of video reports and a preview of IMTS 2014.

06/18/2014

Machine tool builder Hwacheon Machinery America (HMA) will relocate to a new headquarters and technical center in the Chicago suburb of Lincolnshire, Ill., on July 15.

06/18/2014

Machine tool builder Mazak Corp. has invited manufacturers to its "Discover More With Mazak" event July 29 and 30 at the company's Southwest Technology Center in Houston. The company will demonstrate its latest multitasking, 5-axis, milling and turning processes on Mazak machines. Applications engineers will also be available to discuss new ways attendees can streamline their operations. For example, performing multiple processes in a single setup helps minimize material handling and work-in-process. Furthermore, the company encourages attendees to present their part-production challenges so its engineers can offer solutions for overcoming such difficulties.

06/17/2014

MRO distributor MSC Industrial Supply Co., Melville, N.Y., has launched its new ControlPoint inventory management solution, which combines MSC's existing suite of software, hardware and service expertise into a unified inventory management portfolio that allows customers to leverage technology to achieve greater visibility and control over their MRO spending, with the goal of improved productivity and profitability across the supply chains, according to the company.

06/16/2014

Jacob Prak, CEO of Michigan Manufacturing International (MMI), Stevensville, Md., announced the completion of a new MMI plant in Hosur, India, joining MMI locations in Mumbai, Coimbatore and Bangalore, India, and Shanghai, Fuyang, Ningbo, Jinan, Shenzhen, Dongguan and Hong Kong, China.

06/05/2014

Manufacturers nationwide are struggling to find skilled labor, and several community colleges and technical centers around the country have stepped in to fill the void, including a technical training center in Phoenix that offers CNC and manual machining programs. The Maricopa Skill Center offers two machining certificates: CNC machining and manual machining. Students in the program attend class 6 hours a day, Monday through Thursday. The CNC machining program takes about a year to complete.

06/05/2014

Toolmaker TDC Cutting Tools Inc. announced the expansion of its operations and established its global headquarters in Seneca, S.C., resulting in 38 new positions at the facility. The company will invest $8.2 million in the construction of the new TDC Overseas campus, including a 32,000-sq.-ft. office building and a 10,000-sq.-ft. recycling center.

06/04/2014

Since the economic slowdown in 2008, the global sales of business aircraft has been less than 50 percent of the annual sales in 2007; however, as aircraft fleets get older and the economy improves, pent-up demand may stimulate purchases.

06/04/2014

Joe Braun, general manager of Indianapolis machine tool builder Hurco North America, announced that Hurco will hold its inaugural Chipmaker Challenge contest for entrepreneurs in manufacturing. The contest gives new shops the chance to pitch their business plans for a chance to win their choice of a Hurco VMX42i mill or TM8i lathe.

06/03/2014

Toolmaker Seco Tools LLC, Troy, Mich., a technical and supplier sponsor of Andretti Autosport's Verizon IndyCar Series championship racing team, invited customers from across the Midwest to attend an Indy 500 practice day at the Indianapolis Motor Speedway. The day included a meet and greet with IRL driver Marco Andretti, a tour of the Andretti Autosport garage, a catered lunch in the team's suite at the track and a visit to the pits to watch the Indy cars in action.

06/03/2014

The Association for Manufacturing Excellence (AME), Rolling Meadows, Ill., has debuted the AME Manufacturing Job Board, designed to connect job-seeking professionals with the organizations requiring their specific skills.

05/20/2014

In 2003, Kevin Burkett was offered $30,000 for his 1978 Travis Bean "Wedge" guitar and realized it was too valuable to perform with. Most guitarists would make do with using a similar, less-valuable model, but Travis Beans have a distinguishing characteristic that makes them hard to replace — they're made of metal.

05/20/2014

Toolmaker OSG Tap & Die, Glendale Heights, Ill., has announced its "Train the Nation 10 City Tour," a traveling seminar on high-speed machining for the die mold industry.

05/09/2014

Kennametal Inc. completed the relocation of Kennametal Extrude Hone GmbH to its new location in Holzgünz, Germany, after a year of planning and construction. The new building combines several previously separate production and administrative sites in one new building, which is based on "green" design principles. The inauguration and a Technology Days event took place May 6-8 and an employee family day was held May 10. During Technology Days, Guest speakers from industry and academia universities provided insights into market developments and new technologies while Kennametal experts answered questions on metal cutting and other topics.

05/07/2014

Midwest Industrial Tool Grinding Inc. hosted a tour of its Hutchinson, Minn., facility on April 22, 2014, that included representatives from LifeScience Alley (LSA), a trade association with 680 members from U.S. life sciences industry, and the Hutchinson (Minn.) Economic Development Association (EDA). The event at MITGI was part of a larger tour of Minnesota by the LSA and EDA in an effort to cultivate relationships and connect industry partners in the state.

05/05/2014

Steel strapping is effective for bundling materials, but poses a number of problems for a machine shop. Its sharp edges make it something of a workplace hazard, while its long, ungainly shape makes storage and disposal difficult. It's also made of mid-carbon steel, so even though throwing the strapping in the dumpster is the easiest way to handle it, possible profits from recycling are dumped as well.

05/04/2014

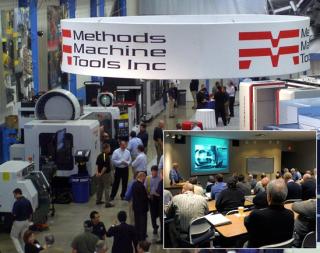

Methods Machine Tools, Inc., a supplier of precision machine tools, automation and accessories, will hold a Grand Opening of their new, expanded Technology Center in Anaheim, Calif. on June 25th and 26th, 2014 from 9:00 a.m. to 5:00 p.m. Manufacturing professionals are welcome and encouraged to attend. The new 11,400 square foot Methods facility supports operations in Southern California, replacing the previous center in Buena Park, Calif.

04/29/2014

Methods Machine Tools Inc., a supplier of machine tools, automation and accessories, announced it is hosting Metal Storm 2014, an open house event taking place June 11-12, 2014 at the company's recently-renovated headquarters and corporate technology center at 71 Union Avenue, Sudbury, Mass. Metal Storm 2014 will feature over 50 machines under power. Attendees are also invited to participate in technical seminars conducted throughout the event by manufacturing industry experts in automotive, aerospace, automation and more.

04/29/2014

Machine tool builder SMTCL-Americas, City of Industry, Calif., has entered in to a partnership with the California State Polytechnic University, Pomona. The written agreement provides a commitment from SMTCL to provide equipment to create a machine lab for engineering students to manufacture components for class projects and international competitions.

04/28/2014

The Association for Manufacturing Excellence Values Veterans (AMEV2) Program held its kick-off symposium on Friday, March 14, 2014 at DMG Mori USA's facility in Hoffman Estates, Ill. This event focused on teaching American employers how to recruit, hire, train and retain veterans.