Industry News

01/13/2021

Big Kaiser Precision Tooling in Hoffman Estates, Illinois, launched a LiveChat feature on its Website, www.BIGKAISER.com, to help current and future customers with their inquiries.

01/12/2021

Verisurf Software partnered with OpenX, an interactive learning platform, to provide comprehensive education courses to those looking to pursue a career in dimensional metrology or expand their skills in specific application areas.

01/11/2021

The Eriez Xtreme RE7 Rare Earth circuit helps remove metals and other impurities and is now incorporated in the company’s tube and grate magnets.

01/08/2021

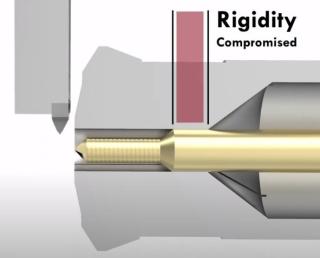

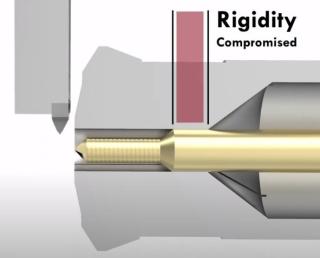

Investing in CNC Swiss technology allows a shop to perform threading operations. Every Swiss machinist should be aware of the latest advancements in this field.

01/07/2021

National Association of Manufacturers President Jay Timmons issues statement slamming rioters who "stormed the U.S. Capitol (yesterday), attacking police officers and first responders because Trump refused to accept defeat in a free and fair election."

01/07/2021

Mastercam has partnered with Edge Factor to equip organizations across North America with information to inspire students and job seekers to pursue career pathways

01/05/2021

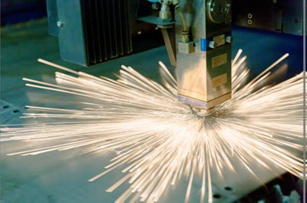

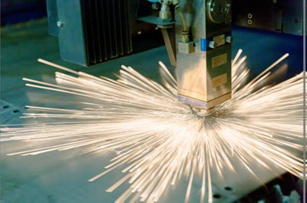

Lasers are used in a myriad number of applications to cut, drill, weld, mark, or structure parts in a wide variety of applications in many industrial sectors to optimize manufacturing processes and satisfy the need for ever increasing quality of components.

01/04/2021

Marcus Ralston explains his outlook regarding three key milestones of the evolution taking the cutting tool industry into the 21st century.

12/29/2020

The costs of cooling lubricants in tool grinding often exceed the costs for grinding wheels. Tool manufacturers who acknowledge this can save money with ultra-fine filtration technology that is optimally adapted to a company’s production capacity and manufacturing requirements. Vomat in Treuen, Germany, is a filtration specialist that offers a range of products that can reduce these costs.

12/28/2020

Inovatools USA LLC in Hartland, Michigan, offers a broad product range of high-performance solid carbide mills that meet the exacting requirements in mold, fixture and die manufacturing.

12/23/2020

Many machine shops are losing tens of thousands of dollars in company profits each year by not implementing quick-change tooling on mills and lathes. Implementing this technology can easily reduce downtime an hour a day.

12/22/2020

A new paper by Forest City Gear engineer Andrew F. Vincent, Ph.D., has been released entitled, A Note on the Design of the Gap Between Helices on a Double-helical Gear. The paper focuses on how the design and how it “imposes a necessary lower bound on the gap between the helices it is meant to produce.”

12/21/2020

Starrag USA named Dan Matticks as its regional manager – Great Lakes for sales. His territory covers Illinois, Wisconsin, Iowa, Minnesota, Michigan, South Dakota, North Dakota and Nebraska.

12/18/2020

Camfil Air Pollution Control (APC), a manufacturer of industrial dust, fume and mist collection systems, is planning to rebuid a manufacturing facility in Jonesboro, Arkansas, that was was destroyed by a tornado in March.

12/16/2020

A tool and process monitoring system from Marposs is part of a project that was named a 2020 Henry Ford Technology Award (HFTA) winning program.

12/15/2020

12/14/2020

Making investments to facilitate operational improvements—and financing those investments in a way that preserves cash flow—will be critical to sustainable growth. Here is what manufacturers should consider to make the most of this opportunity when it comes to achieving value from waste streams.

12/13/2020

Wear pads between the saddle and the machining bed on lathes and CNC machines are being replaced with a wear-resistant polymer known as Vesconite Hilube