Industry News

12/06/2019

Headquartered in Marijampolė, Lithuania, industrial manufacturer Stevila offers precision CNC milling and turning and assembly services on a subcontracting basis, producing parts based on customers’ designs in varying batch sizes. Employing an impressive array of CNC equipment in combination with traditional non-programmed metalworking machines, the company serves clients and partners throughout Europe’s energy, automation, medical, printing machines and other industries. Parts produced by Stevila include everything from expansion bushes and cleaning nozzles to drive-sensor adjust blocks and parts for brake discs.

12/05/2019

The One System Solution grippers from OnRobot are now part of the UR+ program that tests and certifies EoAT products for seamless use with cobots from Universal Robots.

12/05/2019

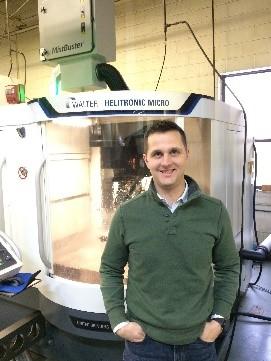

Jason Kleinhenz is one of many Exact Metrology employees at the company’s Cincinnati office. While he does not have an official job title at the company, Kleinhenz describes himself both as an engineer and as a trainer. His job duties include managing and performing training, as well as marketing and creating content for Exact Metrology.

12/04/2019

New Territory Account Manager Jim Ellingsen has been hired by the Hexagon Manufacturing Intelligence Production Software business as a member of the sales team for NCSIMUL manufacturing simulation software.

12/04/2019

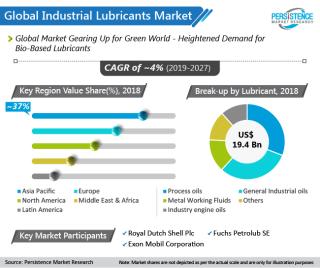

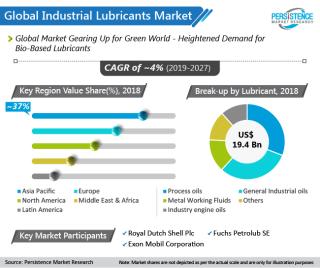

Enhanced operational efficiency offered by industrial lubricants is bolstering their use in the constantly expanding manufacturing sector, as well as other industries such as power generation and oil and gas. Growing use of high-performance lubricants in these end-use industries is expected to drive market growth in the forecast period (2019-2027). As indicated by a new study, the global demand for industrial lubricants will progress moderately through 2027, reaching a value of US$ 28 Bn.

12/04/2019

At ANCA, the company's success has been underpinned by listening to its customer’s needs. Rather than only offer a standard product range, the builder of grinding machines often delivers custom solutions. ANCA’s engineering team can custom design mechanical, electrical, software and process solutions to enhance the standard product range and meet unique customer requirements.

12/02/2019

Macomb, Michigan-based Tooling Tech Group (TTG), a leading provider of highly engineered tools and automated assembly equipment to a wide range of industries, has announced that it has hired Nate Ruhenkamp as a sales manager for the company’s compression mold and thermoform tooling offerings, as well as its Segen Quick Change standard products. He is responsible for managing this group’s sales team, developing new business opportunities and creating synergy with the company’s sales managers in the stamping, die casting and automation sectors.

12/02/2019

OSG USA Inc. announces that Jeff Tennant has been promoted to president.

12/02/2019

Toolcraft, a machine shop in Monroe, Washington, was immediately impressed by the 30 µm repeatability and built-in force/torque sensing in Universal Robots’ new flagship line of collaborative robots. The company needed to automate a challenging, three-operation machine tending task inside its CNC machine and has saved 23% on production costs and increased throughput 43% by using the UR5e cobot.

12/02/2019

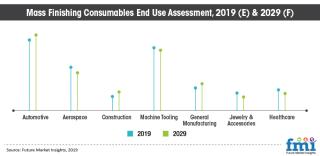

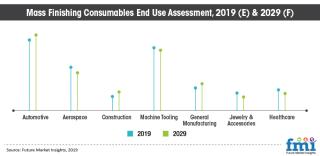

Sales of mass finishing consumables are primarily driven by the increasing demand for surface finishing from various end-use industries such as automotive, aerospace, and general and industrial engineering. As indicated in a new study, the global mass finishing consumables market is estimated to be valued at over US$180 million by the end of 2019, demonstrating moderate growth at a less than 5% CAGR during the forecast period, 2019 to 2029.

11/27/2019

Nueva Precision, Milliken, Colorado, is, for the most part, Eddie Casanueva and his wife Leandra operating out of a garage. And while many job shop owners would want to grow and expand their businesses, the Casanuevas are content with keeping the shop at its current size because, according to them, customers benefit from dealing directly with the person making their parts. This, as well as the shop’s advanced manufacturing technology, makes Nueva Precision a trusted partner to its customers and an agile supplier.

11/27/2019

Digitization has its price. The networking of people, machines and companies not only increases productivity and sustainability, but also raises the risk of a cyberattack. The VDMA Cybersecurity Congress at METAV 2020 on March 11, 2020 offers potential ways of resolving this dilemma. Heinz-Uwe Gernhard is head of the VDMA Security working group and in his principal occupation is responsible for IT security at Robert Bosch in Stuttgart. In an interview he reveals his recipe for success: vigilance training for cyberattacks.

11/26/2019

Test Equipment Distributors LLC (TED) has appointed Jeff Sengenberger as sales representative for nondestructive testing (NDT) equipment and services. He is responsible for sales and technical support in the Midwest U.S., including Iowa, Illinois, Minnesota, Missouri and Wisconsin.

11/26/2019

Monaghan Tooling Group, Dayton, Ohio, welcomes industry veteran Brett Scruggs as a technical account manager. He will work out of his home office in northwest Indiana and is responsible for servicing existing accounts and developing new business in Indiana, Illinois, Wisconsin and Iowa.

11/26/2019

More than 2,000 manufacturers from across North America attended Mazak Corp.’s Discover 2019 event held Nov. 5-7 and 12-13 at the company’s North American manufacturing headquarters in Florence, Kentucky. The event featured over 30 live machine tool demonstrations, and Mazak unveiled for the first time in North America several productivity-enhancing technologies such as its new Mazatrol SmoothAi control, as well as a new mixed reality training and service support system.

11/26/2019

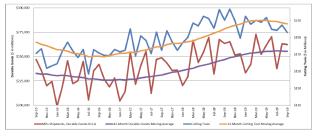

September 2019 U.S. cutting tool consumption totaled $195.9 million, according to the U.S. Cutting Tool Institute (USCTI) and AMT – The Association For Manufacturing Technology. This total, as reported by companies participating in the Cutting Tool Market Report collaboration, was down 4.3 percent from August's $204.7 million and down 7 percent when compared with the $210.6 million reported for September 2018. With a year-to-date total of $1.8 billion, 2019 is up 0.2 percent when compared with 2018. Please note there were revisions to August 2019.

11/26/2019

Arch Cutting Tools hired Charlie Novak Jr. as Arch Specials business development and coordinator. He will be located at Arch-Mentor and report to Brent Sheerer, product manager for Arch Specials (dotted line to Jeff Cederstrom, divisional president of Arch Cutting Tools). Novak joined the company on Nov. 11, Veterans Day, as the toolmaker honored those who’ve served.

11/26/2019

Hermitage, Pennsylvania-based Solar Atmospheres of Western PA has completed construction of a new brazing and assembly room. Though built primarily to accommodate a large aluminum brazing project for a specific customer, the room will be used for other brazing and assembly work, as well.

11/26/2019

API Services, Rockville, Maryland, one of North America’s largest nationwide providers of on-site metrology and laser tracker rental services has launched a recertified laser tracker operation. API Services is a wholly owned division of Automated Precision Inc. (API) whose CEO, Kam Lau, invented the laser tracker. The API Radian laser tracker series offers the smallest lightest and most accurate trackers available.

11/26/2019

Tomenson Machine Works is a third-generation, family-owned manufacturer of precision hydraulic manifolds, with a focus on continuous improvement. The company turned to collaborative automation in its pin-stamping application to improve quality, profitability and worker satisfaction. The OnRobot collaborative RG6 gripper handles dozens of different part sizes with fast and easy changeovers, and sets the stage for ongoing automation in potential applications such as CNC tending, deburring and packaging.