Industry News

01/08/2019

It is October 1978. On Oct. 13, my discovery at the former Matra company in Frankfurt that PCD can be eroded by means of electric sparks was registered at the patents office. In October 2018, we looked back at 40 years of experience in the application of spark erosion for manufacturing and versatile application with polycrystalline blades of PCD- and PCBN-tipped tools.

01/07/2019

The advantages and benefits of the industrial internet of things all start with communication. In industrial applications a simple event increases the advantages as it goes wireless.

01/07/2019

Robots don’t take away jobs.

When companies lose to their competition, that’s when workers lose jobs.

There seems to be this idea: If the robots hadn’t shown up, the jobs would have stayed. But nothing could be further from reality.

Here’s the truth: We aren’t using enough robots.

When companies lose to their competition, that’s when workers lose jobs.

There seems to be this idea: If the robots hadn’t shown up, the jobs would have stayed. But nothing could be further from reality.

Here’s the truth: We aren’t using enough robots.

01/07/2019

The growing use of work robots and the deployment of artificial intelligence have been most disruptive in just those areas of the country that provided President Trump with crucial margins of support in 2016.

01/04/2019

On Dec. 3 Clinkenbeard relocated to a 40,000-square-foot facility in South Beloit, Ill.

01/04/2019

HEBRON, Kentucky, December 4, 2018 – Fives Machining Systems, Inc. a global machine tool and complete manufacturing solutions provider, has announced the relocation of its Machine Tool Services &Solutions business to a new production facility located at 2200 Litton Lane, Hebron, KY 41048.

01/04/2019

Elk Grove Village, IL – Niigata Machine Techno USA, Inc., a specialist in horizontal machining centers, announces the appointment of Gregory Hobbs as its new Vice President of Sales and Marketing.

01/04/2019

SCHAUMBURG, IL (January 2019) – HEIDENHAIN is proud to announce Community College of Denver’s (CCD) Advanced Manufacturing Center (AMC) as the first HEIDENHAIN authorized training partner (ATP) focusing on its CNC controls in North America.

01/04/2019

ARCH Cutting Tools is pleased to announce and welcome Marcus Ralston as Director of Product Management - Standards.

01/04/2019

CRESCO, Pa. — December 20, 2018 — Weiler Abrasives, a provider of abrasives, power brushes and maintenance products for surface conditioning, announced the promotion of Jennifer Hawkins to director of sales – West.

01/04/2019

Erie, PA—Eriez® has appointed James Cooke to the position of Managing Director of Eriez-Australia, according to an announcement by Eriez Senior Director of Asia Pacific Operations and Strategy Jaisen Kohmuench.

01/04/2019

SCHAUMBURG, IL (December 2018) - As the Silicon Valley in California and the West Coast continue to be the hub of the semiconductor manufacturing in the U.S., HEIDENHAIN has expanded its motion systems support by establishing an ETEL facility in Fremont, CA.

01/04/2019

President Donald Trump once named his style of elocution “truthful hyperbole” — what he described as a form of promotion to get people excited. One area the president currently likes to pump up is foreign jobs coming back to the United States.

01/03/2019

Troy, Michigan – December 1, 2018 - HELLER Machine Tools is pleased to announce our new partnership with Compumachine.

01/03/2019

FLORENCE, Ky., December 10, 2018 – With its sights set on further strengthening customer support, especially for those in the high-tech industries, Mazak Corporation has announced it will open a new Mazak San Francisco Technical Center.

01/02/2019

Erie, PA—Eriez® Executive Vice President of Strategy and Development Lukas Guenthardt announces that Jaisen Kohmuench has been promoted to the newly created position of Senior Director of Asia-Pacific Operations and Strategy.

01/02/2019

CRESCO, Pa. — December 6, 2018 — Weiler Abrasives, a provider of abrasives, power brushes and maintenance products for surface conditioning, announced two new positions within the company to serve key metal fabrication industries.

01/02/2019

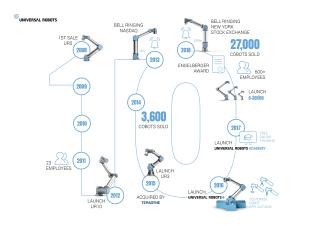

Odense, Denmark, December 5, 2018: When Linatex, a Danish supplier of technical plastics and rubber for industrial applications, bought a UR5 robot arm from Universal Robots (UR) to automate CNC machine tending in December 2008, they did something unthinkable.

01/02/2019

Milwaukee, WI—PFERD INC, a global manufacturer of abrasives, brushes and power tools, has announced the appointment of Mariano Presas as President—Americas effective August 31, 2019.

01/02/2019

Vero Software has hired new Territory Sales Manager Justin Duke, who will oversee sales of the Radan solution for sheet metal in the Great Plains region.