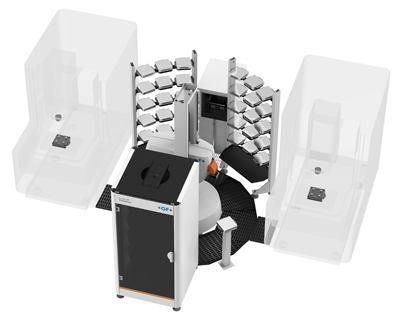

GF Machining Solutions has announced the System 3R TRANSFORMER, a modular automation system designed to integrate with a variety of technologies. With TRANSFORMER, manufacturers can begin by simply automating a single machine and then easily expand to include up to 12 machines within the cell.

A TRANSFORMER cell accommodates a wide range of machining technologies and allows components from different manufacturers to be included within the same call. This open architecture approach allows end users to create an automation cell where each individual component decision is optimized, as opposed to having choice constrained by compatibility.

GF Machining Solutions offers wide range of System 3R tooling systems that allow palletization of workpieces and electrodes of a tremendous range of sizes. The TRANSFORMER system can handle all of these, as well as different tooling systems, allowing it to be incorporated into production systems with existing tooling systems. For maximum flexibility, TRANSFORMER offers additional in-process accessories that can easily be integrated into a cell, including:

• Multiple loading station that can be used without stopping production

• Draining station for emptying workpiece cavities after machining processes

• Washing machine to clean workpieces

• Coordinate measuring machine (CMM) for presetting and/or part inspection

The TRANSFORMER system provides user-friendly cell management software whereby all production data is entered in a structured manner or imported through a data exchange interface for major enterprise resource planning (ERP) systems. The software then controls every aspect of the cell, from automatically loading jobs to machines to recording and monitoring cycle times for each job. The core of the system is an efficient database that uses chip identification of the pallets to ensure that correct data is used for every part in the cell.