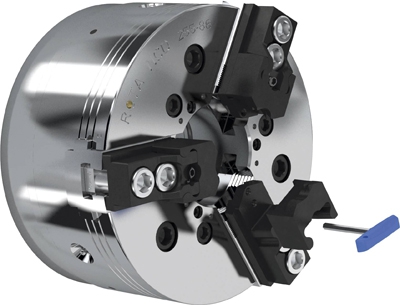

With a change-over time of 5 seconds per jaw, the SCHUNK PRONTO quick jaw change system offers turbo-charged set-up times for all standard lathe chucks with fine serrations of 1⁄16" x 90 degrees and 1.5mm x 60 degrees. The quick-change retrofit set consists of support jaws and clamping inserts. It is suitable for O.D. clamping of pre-machined and finished parts. By using the interchangeable insert, the clamping range can be extended by up to 16mm, without having to re-set the supporting jaw, an increase of 300 percent in comparison to conventional lathe chucks.

For jaw changes with exact repeat accuracy, the locking is released with an Allen key, the jaw is removed and replaced by another, eliminating incorrect positioning. In locked condition, a six-sided form-fit clamping ensures maximum process stability, and provides high force and torque transmission. As required by the application, three supporting jaw variations are available for small, medium, and large, clamping ranges. Four hard claw inserts for various diameters and clamping ranges as well soft interchangeable inserts for finished parts processing are provided. Once they have been turned, the inserts can be used repeatedly on a system. The clamping depth can be varied using a workpiece stop. It is available in size 250 with more sizes to come.

Contact Details

Related Glossary Terms

- lathe

lathe

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.