NCG CAM Solutions Ltd. released NCG CAM v13. This major release includes a number of new features including helical machining, the ability to cap holes, shaft profile export, optional origins, the ability to save values in the edit transform dialogue, the ability to pick a surfaces' colour and make other surfaces the same colour, tapping with chip break, the ability to use lollipop and dovetail cutters for 5-axis surface machining, as well as many enhancements including improvements to the rest machining and waterline linking strategies.

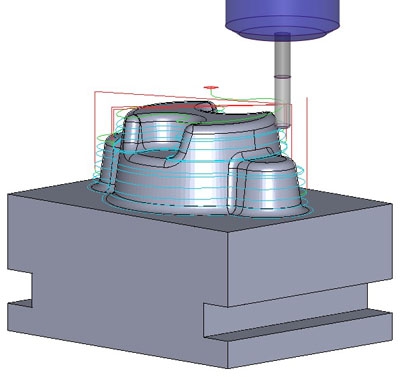

In NCG CAM v13, helical machining passes are a new feature. These passes are generated from a set of horizontal slices, which cut through the surface geometry. The profiles that are created are then joined in a continuously descending ramp, which follows the surface data between the profiles.

Helical passes are expected to be used for semi-finishing and finishing routines. They will reduce the witness lines between Z-level passes, when using waterline passes. The load on the cutter will also be more consistent compared to waterline passes during the linking move down to the next level.

A new feature has been added so that circular holes in the triangulated model data can now be capped, including holes that span across different surfaces. There are two options available with this new feature: Either a circular planar patch can be created at the upper limit of the hole or for holes that pierce a 3D form, a patch that follows the surface edge can be generated. Both methods use a detected holes plan and allow for either, the top, the bottom or both ends of the hole to be capped.

Often a surface on a part will have holes in it (screw holes, ejector/core-pin holes). Capping the hole will allow the user to just machine over the top of them, without dropping down the hole. This will give a smooth machine motion, compared to trying to machine around the hole.

A new feature has been added that allows the results of enabling the "Shaft Profile" to now be exported as a .csv file format. This data can then be used as a template to turn a custom tool holder that allows clearance with the part to be kept to a minimum, providing a more robust toolholder.

Having optional origins is a new feature that allows single points to be converted to datum points. These may then be passed as inputs to machining plans, when required for post-processing.

The ability to save values in the edit transform dialogue now allows the user to save either a single or a combined set of transformations to re-use in another plan or even another database. Selecting 'Save' in the transform dialogue saves the current set of transformations into a pull-down menu; the user can then accept the default name or supply a name that is more suitable. Selecting a saved transformation from the pull-down menu and then selecting "Load" restores the saved transformations and adds them to the current transformations list.

The ability to pick a surface's colour and make other surfaces the same colour now allows it to be possible to select other surfaces and apply the remembered colour to them. This makes it easier for the user to change the colour of numerous different surfaces to be the same as an existing colour.

Tapping with chip break will allow users with suitable machine tool controllers that support this feature (Heidenhain Cycle 209 and others) to implement a 'Chip Break' within the 'Tapping Cycle'. 5-axis machining operations are now able to use Lollipop and Dovetail cutters. Both of these cutter types, will allow the machining of undercut surfaces.

Contact Details

Related Glossary Terms

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.

- undercut

undercut

In numerical-control applications, a cut shorter than the programmed cut resulting after a command change in direction. Also a condition in generated gear teeth when any part of the fillet curve lies inside of a line drawn tangent to the working profile at its point of juncture with the fillet. Undercut may be deliberately introduced to facilitate finishing operations, as in preshaving.