SPRING Technologies announces the release of NCSIMUL Machine 9.2, flagship of its NCSIMUL SOLUTIONS portfolio. Pursuing its commitment to the development of the factory of the future, SPRING Technologies is enriching its solution with additional properties for its Composites module and enhancing its capabilities in terms of automation, ergonomics and, ultimately end-user productivity.

"NCSIMUL Machine is our flagship. We have been developing the solution for 17 years and we progress it with state-of-the-art technology, drawing on our expertise in industry applications, and addressing market needs," explains Olivier Bellaton, Managing Director of SPRING Technologies. "With Version 9.2, we bring our users the very best technology to automate tasks that deliver no added value, and secure the information, data exchange and tool paths Ì¢‰Ûù‰â all of this in a 3D graphic environment. Each new version brings us a step closer to SMART INDUSTRY."

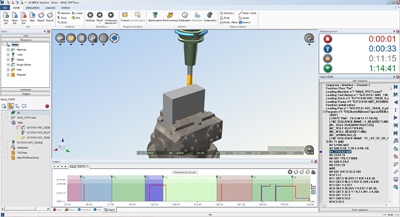

With NCSIMUL Machine users can:

• Control the global machining process;

• Simulate, check, optimize and modify their machining programs;

• Detect collisions;

• Optimize cutting conditions;

• Release a standardized technical content throughout the workshop.

Contact Details

Related Glossary Terms

- composites

composites

Materials composed of different elements, with one element normally embedded in another, held together by a compatible binder.