Beryllium provides many desirable properties for a host of applications, such as aerospace and automotive. These include having a high melting point with excellent thermal conductivity, being stiffer than steel by weight, and being extremely lightweight. “The only lighter metal is lithium, but you can’t expose lithium to oxygen without it spontaneously combusting,” said Anthony Dutton, CEO and director of materials provider IBC Advanced Alloys Corp.

When beryllium is alloyed with aluminum, the resulting components are 22 percent lighter than aluminum ones and provide increased stability through a large operational temperature range. Machining beryllium-aluminum (Be-Al) billets, typically made of hot isostatic-pressed metallic powders, is time-consuming, and the resulting chips can’t be recycled as easily as, say, steel or copper. Dutton explained this is because the chips must be rinsed, repowdered and essentially put back through the production cycle. “In terms of an economic analysis, you would effectively account for that yield loss being 100 percent.”

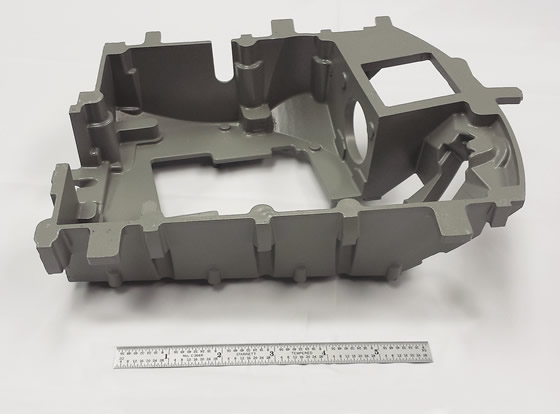

Beralcast beryllium-aluminum parts are suitable for up to 80 percent of the applications for that alloy, including this reconnaissance pod electrical enclosure for a fighter plane.

One solution to this problem is casting Be-Al alloys to a near-net shape and only finish-machining specific features for precise interfaces and tight tolerance requirements that cannot be achieved with a raw investment casting. This would reduce the cost and lead times for the parts.

One challenge, though, is the that the melting and freezing temperatures of the two metals are extremely divergent. This makes it difficult to get both to behave in a uniform manner in the same temperature range and ensure equal distribution when casting without causing the problem of aluminum segregation.

IBC’s subsidiary, IBC Engineered Materials Corp., Willington, Mass., overcame this challenge by developing a proprietary process, becoming the only company that can successfully cast the alloy, according to Dutton.

The company’s Beralcast Be-Al alloys, in addition to being a lower-cost replacement material for Be-Al billets, can replace cast aluminum, magnesium, titanium, metal-matrix composites and nonmetallic composites, IBC stated. CFO Simon Anderson noted Beralcast 363 is the family’s main product and has a composition of about 65 percent beryllium and 35 percent aluminum by weight. “If you’re doing high-volume production, you can produce more components, more quickly by casting them,” he said.

Although fully machined parts can handle higher stresses than cast parts made of the same alloy, Dutton said Beralcast parts are well-suited for 70 to 80 percent of the applications for Be-Al parts. The cast parts cost 40 to 70 percent less than comparable machined parts, depending on the application, with part geometry being the biggest factor in the savings, he added.

For example, Lockheed Martin Missile and Fire Control Systems selected IBC to provide Beralcast components for an electro-optical targeting system assembly on the F-35 Lightning II fighter plane, with an azimuth gimbal housing being the first component.

Dutton pointed out that IBC is targeting the aerospace industry for Beralcast parts because that’s where the majority of Be-Al alloys are consumed. “When we talk to potential customers, we don’t have to spend any time talking about the material per se,” he said. “All we need to do is make them understand that if they were to move from a machined part to a cast part, they could save a lot of money and time.”

For more information about IBC Advanced Alloys Corp., Vancouver, B.C., call (604) 685-6263 or visit www.ibcadvancedalloys.com.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- composites

composites

Materials composed of different elements, with one element normally embedded in another, held together by a compatible binder.

- investment casting

investment casting

1. Casting metal into a mold produced by surrounding (investing) an expandable pattern with a refractory slurry that sets at room temperature, after which the wax, plastic or frozen-mercury pattern is removed through the use of heat. Also called precision casting or lost-wax process. 2. Part made by the investment-casting process.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.