Ceramics are known for their inherent hardness and heat resistance, which makes them suitable for cutting hardened steels and heat-resistant superalloys. They can run at higher cutting speeds than carbide grades, and the success and failure rate of these tools generally comes down to the rigidity and stability of the machine tool. Presented here are five key factors shaping the ceramic tool market.

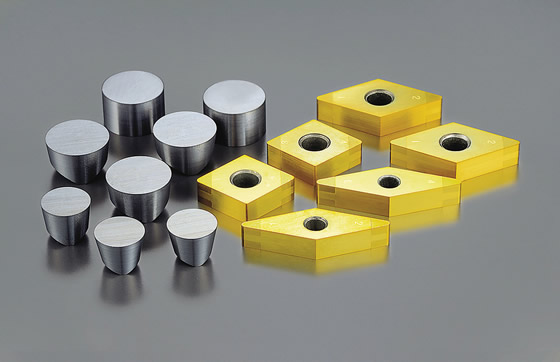

The ceramic tool market is expanding thanks to machine, ceramic material and programming improvements. Image courtesy Greenleaf.

1. The technology is evolving. Ceramic tools will eventually be the preferred choice for machining both challenging and mundane materials, according to Bill Greenleaf, national sales and marketing manager for Greenleaf Corp., Saegertown, Pa. This will be the result of continued advancements in ceramic materials, application expertise and machine tool technology.

“Today’s machine tools are better equipped to take advantage of the elevated performance of ceramic tools,” he said. “CAM packages are providing more canned programming techniques, and the development of new insert grades are engineered to reach higher feed rates and cutting speeds and extend tool life.”

Neal Buschmohle, marketing and product development manager at NTK Cutting Tools USA, Wixom, Mich., said the industry is developing grades that increase wear resistance, toughness, consistency and repeatability. “Many of these products, such as alumina ceramics, are getting close to the productivity found in CBN tools when hard turning. My guess is we’ll get there within the next 3 years. Some of our ceramic grades have already replaced CBN in certain applications.”

One of the biggest trends in ceramics is the availability of more complex chamfers and edge preps, said Eric Jenkins, senior applications engineer at Kyocera Precision Tools Inc., Hendersonville, N.C. “These are critical to the performance of the tool. Ceramics used for hard turning, for example, normally require a chamfered edge to improve insert strength. This is due to the increase in hard turning cutting forces, which can be 30 to 80 percent greater than the forces seen in traditional soft machining processes.”

2. Ceramic tools require a specific skill set. The application of ceramic tools is unique when compared to carbide cutters. “The principles can be easily learned, but they are profound enough that someone new to ceramic machining should be aware of them prior to attempting their use,” Greenleaf said. “We routinely train our customers in proper ceramic application skills either through dedicated classroom programs or through factory-trained sales and service engineers.”

Jenkins agreed that ceramic tool knowledge is important at the beginning. “Operators should be instructed to handle ceramics with care; don’t throw them in the toolbox, for example,” he said. “They should also take care when indexing the inserts, because overtightening a clamp screw may crack a ceramic insert. Operators should also trust the programming. Higher cutting speeds are normal with these tools, but it may look unusual to an operator running the tools for the first time.”

Many ceramic cutting tools, alumina for example, are getting close to the productivity found in PCBN tools when hard turning. Image courtesy NTK Cutting Tools.

The willingness to learn these skills comes down to the machine operator, who might want to simply stand in front of the machine and go through the motions, according to Buschmohle. “Others might have some programming background and can easily identify the productivity improvements available with ceramic tools. They see the efficiency gains and understand how these tools can help make their job easier and more efficient. These are the kind of operators that become your best salesmen for the technology.”

3. Machine tool stability is key to success. Ceramics do not require anything special from the machine other than rigidity, according to Jenkins. “The majority of machine tools I have encountered in the field are capable of running ceramics, but the difference between success and failure is often related to the stability of the entire process. This includes the placement of the machine tool on the shop floor, how the workpiece is held and the toolholder overhang.”

Carbide tools are brittle and, therefore, also susceptible to rigidity issues, but carbides are generally tougher than ceramics, and, as a result, can be more durable in unstable conditions. The trade-off, however, is the sacrifice in cutting speed compared to ceramics. “A ceramic-savvy shop can machine an aerospace component in a fraction of the time that it will take for a carbide-only shop to do the same job,” Jenkins said.

Many companies run old, low-power machine tools into the ground instead of upgrading to new equipment, which can be a disadvantage for ceramic tools. “The lack of horsepower makes a difference,” Buschmohle said. “Our customers that own the latest machine tool technology have a significant advantage with more tooling options.”

4. Social media shows tricks of the trade. In the past, ceramic tools were considered a niche technology. This perception is changing thanks partly to the online manufacturing community.

“The use of social media and the Internet has provided more opportunities for machinists and programmers to share the application techniques required to successfully use advanced ceramic tools,” Greenleaf said.

The majority of machines are capable of running ceramic tools, but the difference between success and failure is often related to stability. Image courtesy Kyocera Precision Tools.

He’s right to praise Facebook, Twitter and YouTube—sites that continue to publish instructional videos and tips that cover everything from programming techniques to cost-savings analysis for ceramic tools. And the message is well-received: Thousands of comments, questions and video shares prove that if someone is wondering if he can use ceramic tools for a certain application, the Internet has the potential answer—just make sure to verify.

5. Growing end user market. The end user market for ceramics is expanding because more exotic materials are being cut. “In the past, ceramics may have been applied more exclusively in large production facilities. Today, the materials, machine tools and technology needed for success can be found in most machine shops,” Greenleaf said.

Jenkins also believes the market is growing. “The aerospace and medical markets are showing the highest growth trends, and both of these markets machine materials that can utilize ceramics to prolong tool life and shorten cycle times,” he said.

“There are so many new products being developed for aerospace alone,” Buschmohle said. “I’m an optimist, so I think this market will really flourish in the next 5 to 10 years. Aerospace should be the largest growth area.”

Additionally, Buschmole said he sees significant growth in the trucking, braking and power generation industries.

In the end, the impact ceramics can make in the cutting tool market will come down to a manufacturer’s willingness to experiment on the shop floor. Those that focus on increasing productivity will flourish.

“Whether it’s a small job shop or a big manufacturing facility, everything is competitive in ceramics. The market is wide open right now,” Buschmohle said. “A company can’t continue to ride carbide when their competitor is running ceramics eight to 10 times faster. More parts out the door makes more money.” CTE

About the Author: Matthew Jaster is senior editor for CTE. Contact him at (847) 714-0174 or [email protected].

About the Author: Matthew Jaster is senior editor for CTE. Contact him at (847) 714-0174 or [email protected].

New materials and processes

NTK Cutting Tools USA released its aerospace-grade BIDEMICS for machining high-temperature alloys at high speeds while extending tool life and imparting fine surface finishes. Grades include JX1, with up to 1,600-sfm speed capability, longer tool life and better wear and notching resistance vs. whisker-reinforced ceramics, according to the company. Additionally, the JP2 grade is for machining at speeds 10 to 15 times faster than carbide and includes a strong brazing technology. “If customers don’t have high-speed machining, they can look at BIDEMICS as a productivity upgrade, featuring two to three times better tool life,” NTK’s Neal Buschmohle said. “If they already have HSM, they can go from 800 to 1,600 sfm and get two parts out the door for every one part they did before.”

R&D has paved the way for new ceramic materials and coatings, like NTK’s aerospace-grade BIDEMICS, that will have a greater impact on high-speed machining. Image courtesy NTK Cutting Tools.

Kyocera Precision Tools Inc. offers MEGACOAT, a proprietary PVD coating process. The company reports that the coating has a higher hardness and a higher heat resistance than TiAlN, which is often applied for its heat-resistant property. “Our Al2O3-based ceramic grade PT600M is used for hard turning and utilizes the MEGACOAT to prolong tool life,” said Kyocera’s Eric Jenkins.

Greenleaf Corp. has developed a coating with strong adhesion to its whisker-reinforced ceramic substrate. Greenleaf says its coated WG-600 and WG-700 whisker-reinforced ceramic grades extend tool life at higher cutting speeds than uncoated whisker-reinforced ceramics. WG-700 features an optimized substrate to perform at higher feed rates than other whisker-reinforced ceramics. “Our new phase-toughened ceramic, XSYTIN-1, is the strongest ceramic grade that we’ve ever produced,” Greenleaf’s Bill Greenleaf said. “It is engineered to operate at very high feed rates and has found success in materials that we typically would not expect a ceramic to perform well. It also seems to perform equally well across a variety of materials that previously would fall within the domain of multiple ceramic grades.”

—M. Jaster

Contributors

Greenleaf Corp.

(814) 763-2915

www.greenleafcorporation.com

Kyocera Precision Tools Inc.

(800) 823-7284

www.kyoceraprecisiontools.com

NTK Cutting Tools USA

(866) 900-9800

www.ntkcuttingtools.com

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- ceramics

ceramics

Cutting tool materials based on aluminum oxide and silicon nitride. Ceramic tools can withstand higher cutting speeds than cemented carbide tools when machining hardened steels, cast irons and high-temperature alloys.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- cubic boron nitride ( CBN)

cubic boron nitride ( CBN)

Crystal manufactured from boron nitride under high pressure and temperature. Used to cut hard-to-machine ferrous and nickel-base materials up to 70 HRC. Second hardest material after diamond. See superabrasive tools.

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- hard turning

hard turning

Single-point cutting of a workpiece that has a hardness value higher than 45 HRC.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- polycrystalline cubic boron nitride ( PCBN)

polycrystalline cubic boron nitride ( PCBN)

Cutting tool material consisting of polycrystalline cubic boron nitride with a metallic or ceramic binder. PCBN is available either as a tip brazed to a carbide insert carrier or as a solid insert. Primarily used for cutting hardened ferrous alloys.

- shaping

shaping

Using a shaper primarily to produce flat surfaces in horizontal, vertical or angular planes. It can also include the machining of curved surfaces, helixes, serrations and special work involving odd and irregular shapes. Often used for prototype or short-run manufacturing to eliminate the need for expensive special tooling or processes.

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.

- titanium aluminum nitride ( TiAlN)

titanium aluminum nitride ( TiAlN)

Often used as a tool coating. AlTiN indicates the aluminum content is greater than the titanium. See coated tools.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.