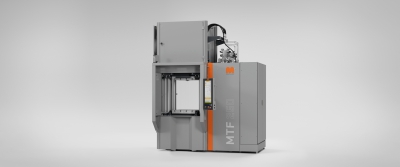

Machinery + Planning Inc. off the fully hydraulic Maplan MTF 1500/250 from the new MTF-range. As a vertical beam injection molding machine, it brings the topics of user-friendliness and ergonomics to the forefront, according to the company.

The machine stands for optimised ergonomics and has a reduced operating height of just 935 mm. It therefore provides significantly better accessibility to the tool. The clever "one-piece design" enables the machine to be transported without removing the hydraulics or the injection unit. Only the switch cabinet is removed and this is done with just a few movements. This reduces commissioning time at the customer's site significantly. Relocating the machine within the customer production site is therefore an easy task.

The machine has a new concept for the clamping unit, which has been optimised by FEM analyses. It ensures that the clamping system is significantly more rigid with minimal plate bending and high plate parallelism. Enlarged, double-acting fast stroke cylinders can move even massive tools better and above all quieter. The generous distance between the tie-bars of 680 mm ensures that there is more scope for automation solutions.

The switch cabinet is equipped with an integrated cooling device to ensure that the control components are reliable and have a long service life even if there is extensive equipment. The 250 machine supplements the existing 3,200kN version thanks to its injection volume of 1,500 to 2,500 cm³.