In today’s fast-moving, just-in-time manufacturing markets, quick access to production data is critical to meeting customer demands. With Global Shop Solutions new manufacturing dashboards, manufacturers can now make smarter business decisions by visualizing their data anywhere on the shop floor and throughout the business.

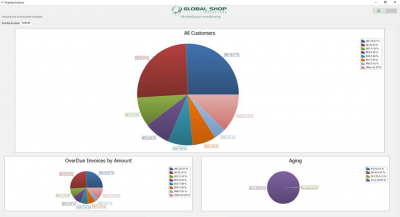

Global Shop Solutions has created more than a dozen dashboards that organize and display data ranging from open sales and work orders to shipping schedules, purchasing, bill of materials status, and even vendor performance. Built on Microsoft’s popular .NET platform, the dashboards provide a new level of customization, allowing users to make changes right on the screen without having to change the underlying code.

“Our ERP software has always been known for its superb visibility of data,” says Global Shop Solutions CEO Dusty Alexander, “and now we’ve taken that one step further. The result is our suite of dashboards that enables manufacturers to put the exact data they want on display anywhere in their business at any time.”

Global Shop Solutions offers the interactive dashboards to their customers at no additional cost. ERP software users simply download the dashboards from a secure web portal and install in a matter of minutes. Standard features include:

• Various tables for customized views

• Drag columns to rearrange, group and sort

• Right-click a column to apply a filter or hide

• Expandable graphs by a simple double-click

• One-click export to Excel

• Drill into standard Global Shop Solutions transactions

• Color coded for ease of use

• Save column settings and selections

The dashboards also offer a “refresh” feature that keep the data as live as possible and include the ability to drill into more detail on work orders, inventory, or whatever data you need to access.

Global Shop Solutions customer, Materials Coordinator Duke Goudeau with Hayes Manufacturing, uses the “refresh” feature to keep his business running efficiently. “We use the .NET Dashboards as a part of our day-to-day processes and meetings,” shares Goudeau. “They’re amazing compared to looking at reports, plus you can modify the view. It is so much easier using visual aids when you have a group of people you are presenting problems to or showing achievements that have been made.”

According to Global Shop Solutions Custom Development Manager Ryan Young, customers are displaying the dashboards on TV monitors on the shop floor, shipping department and other areas throughout the business.

“As an example, the production department might utilize an open job dashboard to monitor WIP and job status,” Young says. “At the same time, a shipping dashboard might be displayed by the dock so personnel can see what needs to get out the door. Our customers are using dashboards in certain instances to replace a printed report.

Instead of having to run a menu item, select and print the report, they have live, interactive data on the screen at all times.”

Contact Details

Related Glossary Terms

- just-in-time ( JIT)

just-in-time ( JIT)

Philosophy based on identifying, then removing, impediments to productivity. Applies to machining processes, inventory control, rejects, changeover time and other elements affecting production.

- web

web

On a rotating tool, the portion of the tool body that joins the lands. Web is thicker at the shank end, relative to the point end, providing maximum torsional strength.