Typically in a scrap handling process, the how and where the scrap is collected and disposed of is not part of the conveyor system's design—but should be. That how and where could be crucial to the longevity of your conveyor. PRAB Inc., Kalamazoo, Mich., has a free, downloadable white paper on "The Importance of Design Elements in Maximizing the Life of Your Steel Belt Conveyor," that details what to be aware of.

For example, the longevity of the conveyor may be compromised if the scrap being discharged is falling a significant height. From a stamping press, the fall can range from 3' up to 10'. A drop like that can result in damage to the conveyor belt, significantly reducing the reliability and causing future maintenance to the conveyor. Not to mention, the repetitive force of this nature can cause your conveyor to fail far sooner than it ever should.

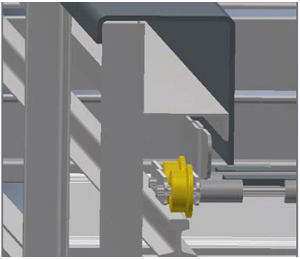

However, there are design elements such as impact plates that can be put into place that will help maximize the life of your under press steel belt conveyor. Impact plates are pieces of raised metal that are welded to the conveyor belt to protect it from the falling scrap.

The entire white paper by PRAB mechanical engineer Mike Proos is available as a PDF download, here.