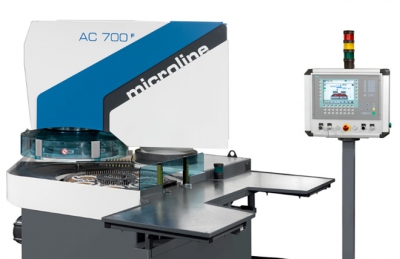

Peter Wolters AC 700 double-side batch processing machine has been designed for high-precision series processing of small workpieces. Due to its modular construction, AC 700 can be used as a fine grinding, lapping, honing and polishing machine.

Machine Features:

- Like all machines of the microLine series, AC 700 is based on tried and tested core components such as high-precision, pneumatic pressure system, non-contact micro measuring controller, powerful drive technology and the PC-assisted machine control. Software has been developed by Peter Wolters, which makes it possible to intuitively operate the machine entirely by menus. Swivel-mounted cabinet and frame allow access to the machine interior.

- The machine is available with different rotating devices, drive powers and wheel speeds to match the widest possible range of workpieces. This ensures optimal machine configuration for every application.

- AC 700 is available with well-known, tried and tested accessories such as gap formation, alignment device, and dosing system for fine grinding/lapping or polishing compound. Accessories such as measuring sensor and post-process measurement provide data for statistical process control and offer process security when processing critical work pieces. "Data Care," the proprietary analysis tool, captures all controller data and thus is the suitable platform for analytic process evaluation, optimization and fault analysis.

- AC 700 can load and process workpieces with a maximum diameter of 240 mm and a maximum thickness of 75 mm.

Contact Details

Related Glossary Terms

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- lapping

lapping

Finishing operation in which a loose, fine-grain abrasive in a liquid medium abrades material. Extremely accurate process that corrects minor shape imperfections, refines surface finishes and produces a close fit between mating surfaces.

- modular design ( modular construction)

modular design ( modular construction)

Manufacturing of a product in subassemblies that permits fast and simple replacement of defective assemblies and tailoring of the product for different purposes. See interchangeable parts.

- polishing

polishing

Abrasive process that improves surface finish and blends contours. Abrasive particles attached to a flexible backing abrade the workpiece.

- process control

process control

Method of monitoring a process. Relates to electronic hardware and instrumentation used in automated process control. See in-process gaging, inspection; SPC, statistical process control.

- statistical process control ( SPC)

statistical process control ( SPC)

Statistical techniques to measure and analyze the extent to which a process deviates from a set standard.