Large-volume workpieces or long sections that are processed by machining from multiple sides often fit poorly or not at all in standard machines. If, additionally, a high output is required, the construction of a special machine makes economic sense.

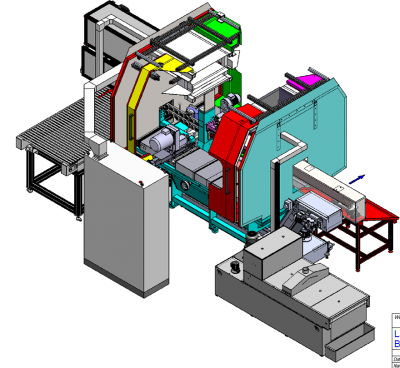

For such workpiece scenarios, the usual fixtures are no longer sufficient and extraordinary solutions are necessary. To fix safely and accurately a long profile or bulky workpiece over its entire length without deforming, every application is a challenge for the designer. In the illustrated system, the operations are done simultaneously from two sides.

The modular system of Suhner enables the creation of special machines for various applications of profile machining. The illustrated machine produces precision rail guides and was designed and built by the Suhner division for special machines.

The rapid transfer of the pieces was as important as the precise and rapid loading, unloading and fixturing. The geometry of the fixture device allows simultaneous drilling in steps, on the holes in tool steel. The high-pressure internal cooling of the carbide tools allows an excellent drilling performance. The installation consists of two spindles that perform, in less than 3 minutes, 140 drilling operations, loading and unloading included. The positioning of the spindle and the actual drilling operation takes place in about two seconds.

The automatic loading and unloading allows predictable autonomy. Stacks and checking the position and the feeding of bulky work pieces must be adapted individually to the workpieces.

Assembly profiles, profiles for windows and doors, plus steel profiles of any kind are often cut for further cost optimization from bar stock. In such projects, additional considerations for the optimal utilization of the raw material and the handling of the remaining piece in the machine cycle are necessary.

Contact Details

Related Glossary Terms

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.