BobCAD-CAM Inc. announces the release of its new SolidWorks CAM plug-in, BobCAM V7 for SolidWorks.

“We are very excited to present a ton of enhancements to the BobCAM for SolidWorks product line. Users now have the ability to work in both Part and Assembly mode now in the new V7. This really gives users all the options to harness the power of SolidWorks to be used in toolpathing processes. Every user, no matter which product they use, is going to see all the benefits of the V7 product versus previous versions,” says Greg Myers of BobCAD-CAM’s developmental team.

The new V7 has been optimized to deliver a simplistic, yet powerful workflow that delivers better part finishes in less time. Listed below are the top 10 features from the new BobCAM V7 for SolidWorks.

1. BobCAM in Assembly

BobCAM V7 for SolidWorks allows users to fully utilize SolidWorks' part and assembly files for part programming.

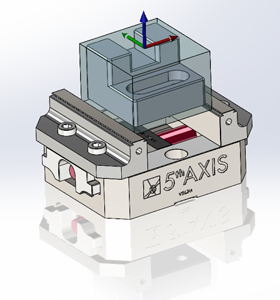

2. Fixtures for Simulation

This new feature in V7 gives the user a better visualization of their part setup in a simulation.

3. Advanced Feedrate Mapping

BobCAM V7 for SolidWorks provides optimized feedrates for more efficient programs.

4. Toolpath Editor

The toolpath editor provides user-customized toolpaths for better performance.

5. Advanced Pocketing Patterns

Users now have additional options for pocketing cycles to choose from in the new V7.

6. Drag Knife

Choose the drag Knife cutting strategy for cardboard, vinyl, leather and other thin materials.

7. Trim Extend/Minimize Retract

BobCAM V7 for SolidWorks features enhanced user control to optimize cycle times.

8. Rotary Rough and Finish 4 Axis

Users that have 4-axis capabilities will experience easier and faster programming of complex 4-axis roughing and finishing operations.

9. Multiaxis Posting Enhancements

New multiaxis posting enhancements provide setup and operator friendly G-code output for 4- and 5-axis posting.

10. NC Editor

Our V7 Standard editor comes packed with more features that are easier to use.

Contact Details

Related Glossary Terms

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.