The One System Solution grippers from OnRobot are now part of the UR+ program that tests and certifies EoAT products for seamless use with cobots from Universal Robots.

“Our unified URCap software is a key differentiator for our grippers, sensors and tool changers. Now, we have a single URCap that automatically identifies the OnRobot tool that is mounted on a UR robot,” says Kristian Hulgard, general manager of OnRobot’s Americas division. “The end users no longer have to worry about different URCaps for multiple tools, they can effortlessly plug and play various OnRobot products; for example, an RG2 two-finger gripper can be implemented with a VG10 vacuum gripper in one cycle, achieving optimized utilization of a single UR robot.”

Early Ewing, global head of Universal Robots’ UR+ program, sees the certification of OnRobot’s new products as an example of the continued close collaboration between the two companies. “We are delighted to work together with OnRobot in producing high-quality products for the automation market,” he says. “The URCap now allows OnRobot’s grippers to utilize all the benefits of our new line of e-Series cobots in terms of fast digital feedback and repeatability.”

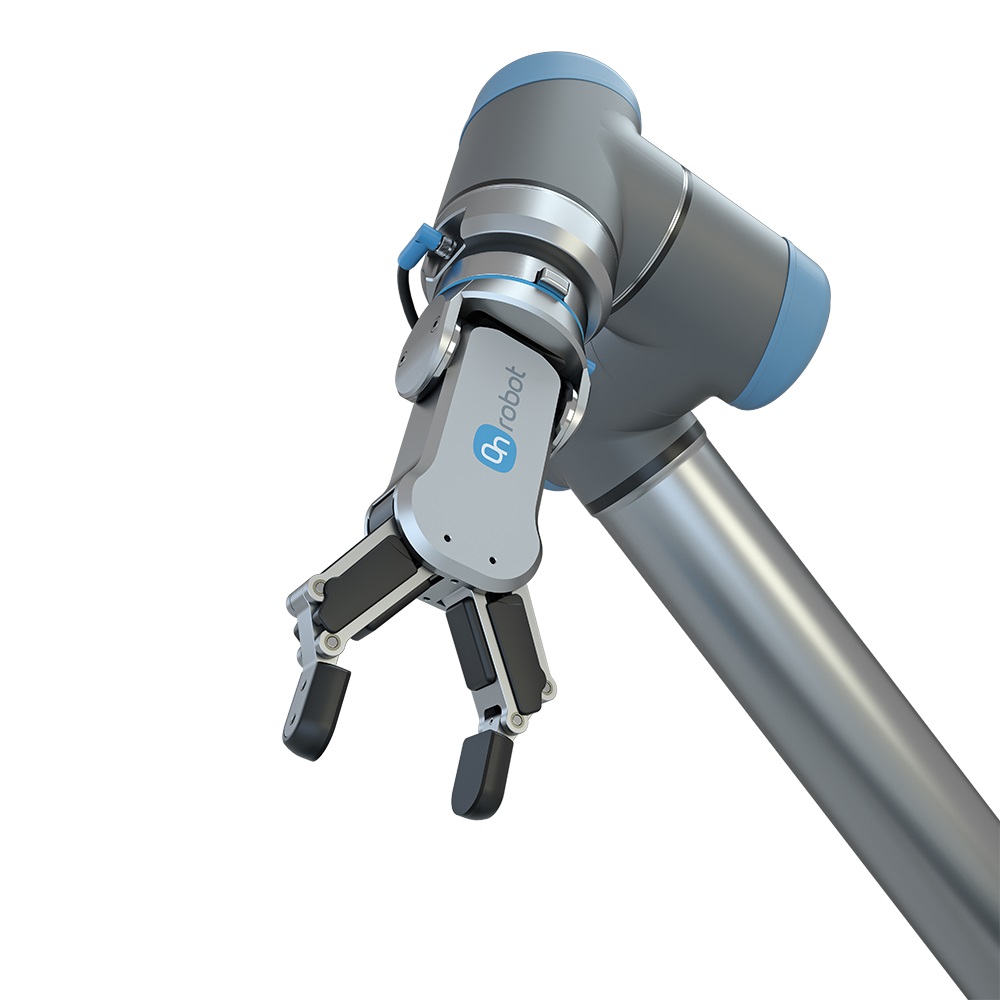

OnRobot’s unified URCap can be installed in UR’s Polyscope operating system when installing OnRobot software. The installation requires the identification of just one product; the software automatically identifies additional OnRobot products. With the One System Solution, all OnRobot products have a unified mechanical and communications interface based on the OnRobot Quick Changer, which is now an integrated part of all OnRobot products. The Quick Changer allows manufacturers to simply click OnRobot grippers onto the UR cobot arm for instant deployment. The only cable coming out of the chain is from the Quick Changer, eliminating the need to disconnect/connect cables. An additional Dual Quick Changer incorporates these same new capabilities while allowing the use of two tools in one cycle, mixing and matching to suit application needs and maximizing robot utilization.