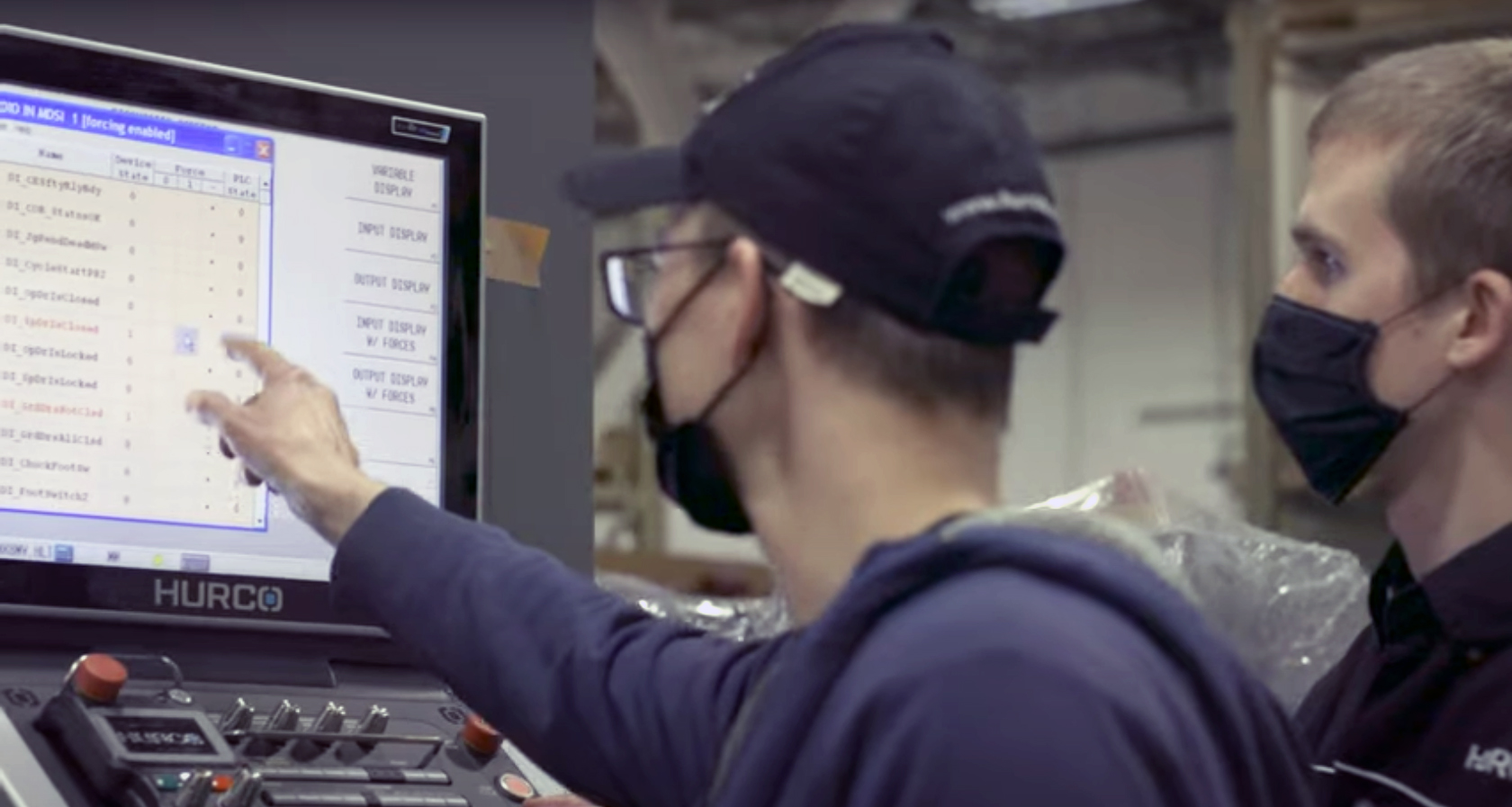

Hurco North America launched the Field Service Apprenticeship (FSA) program, which is a new 2-year apprenticeship program that starts with 12-weeks of industry training that merges hands-on training and repair of CNC machines with classroom materials.

Cory Miller, general manager of Indianapolis-based Hurco North America, said, “We are fortunate to have a tenured service and support team at Hurco. The knowledge they have amassed is extremely valuable and the FSA program will allow them to transfer that knowledge to the next generation of service engineers with intensive training about the machine tool industry, how they are built, the technology that powers our CNC machines, how to diagnose issues, and service machines.”

While candidates with a degree or working toward one are encouraged to apply, candidates who are mechanically inclined with no industry or engineering experience are also encouraged to apply for the FSA. “We know there are people outside our industry who would excel at a career as a service engineer for machine tools, but might not have been exposed to our industry. We believe the FSA will be important to bridge the skills gap and introduce more people to the machine tool industry, which benefits the industry as a whole,” said Miller.

“If you have a strong work ethic, like to learn how things work, like hands-on training, and want a career instead of a job, this apprenticeship is for you,” said Mark Gilmore, Service Manager for Hurco North America.

Field service engineers will ultimately be ambassadors for Hurco Companies, Inc.—working to provide technical support, training, and service of state-of-the-art CNC machines at customers’ facilities across the country. Continuous training on emerging technologies in CNC controls, robot integration, 5-axis machine and multi-spindle lathe installation, repair, and applications will also be provided after completion of the apprenticeship.

The FSA program will take place at Hurco’s headquarters in Indianapolis, Indiana. For additional information and to apply, please visit Hurco.com/Apprentice.

For more information on Hurco Companies Inc., phone 800-634-2416 or visit www.hurco.com.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- lathe

lathe

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.