The Ceratizit Group is preparing to launch a global online event, “It’s Tool Time,” that will focus on the value of process optimization through a variety of interactive machining demonstrations and presentations.

A follow-up to its 2020 debut show, this interactive event will feature a team of experts during two sessions on June 17, 2021. The first session is from 6:30 a.m. to 7:30 a.m. (CT), and features an introduction by CERATIZIT GROUP Board Members Thierry Wolter and Andreas Kordwig. Additional topics include digital machine monitoring, additive manufacturing, future-oriented logistics and the Ceratizit-WNT Professional Women’s Racing Team.

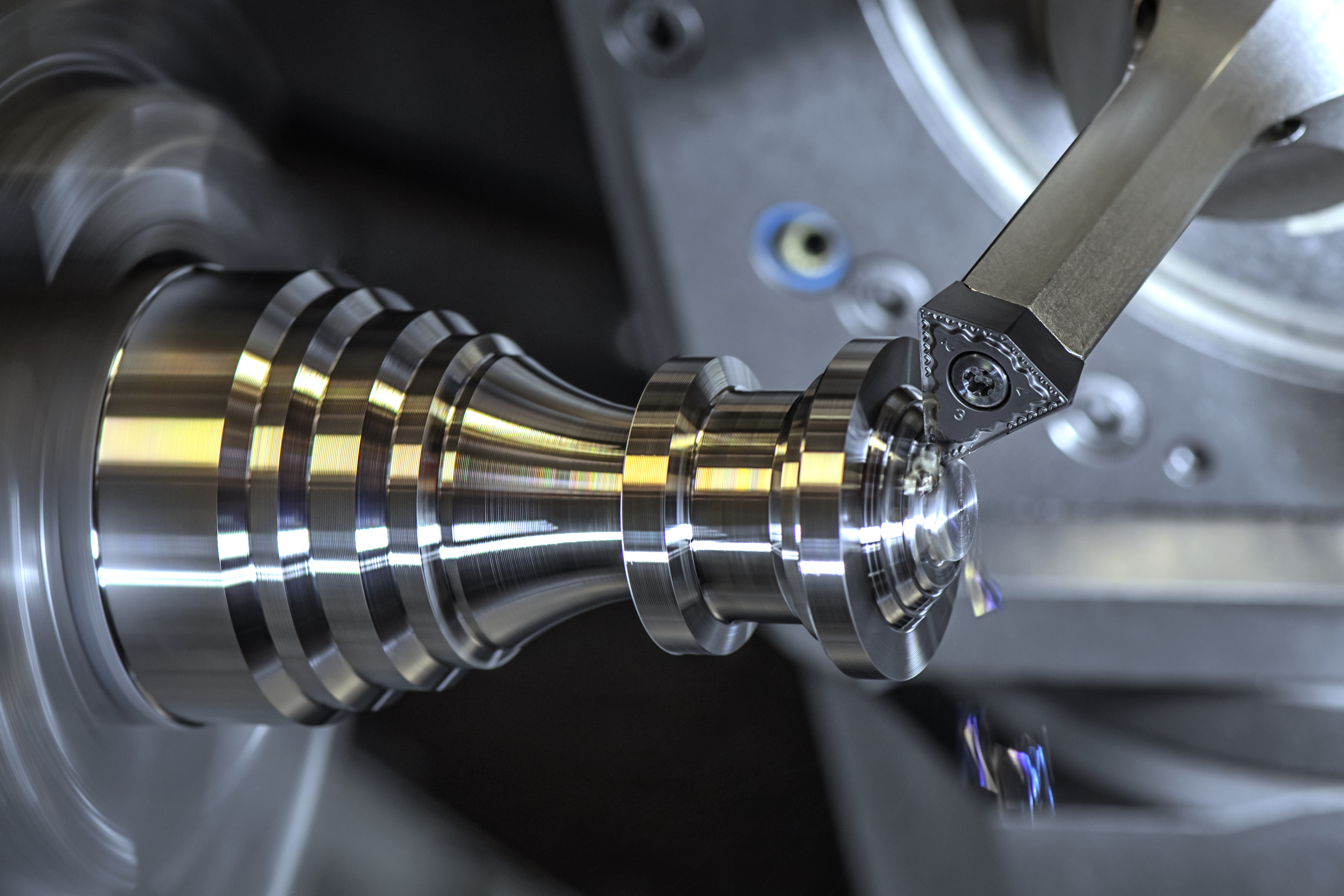

The second session is from 9:00 a.m. to 10:30 a.m. (CT), 10:00 am to 11:30 a.m. (ET) and features four technical programs including: High Dynamic Turning with FreeTurn; LiveTechPro remote video support platform; how an enduro bike was milled from a single block of aluminum; and project engineering.

“In 2020, we launched CERATIZIT – It’s Tool Time! and brought a brand-new format to our sector– a B2B infotainment show all about cutting tools,” said Wolter. “Off the back of this success, we are excited to announce that the sequel will be bigger, better, and packed with fascinating new innovations and hot industry topics. ”

To join CERATIZIT – It’s Tool Time! – Optimizing your Processes live from 6:30 am CT/7:30 am ET on June 17, 2021, or to watch the videos on-demand after the event, register here: https://www.itstooltime.tv/en/

Contact Details

Related Glossary Terms

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.