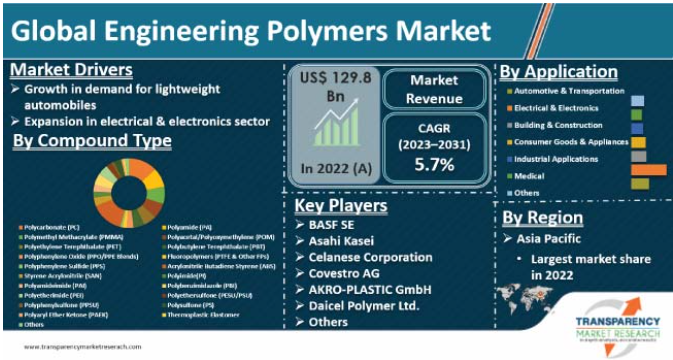

The global engineering polymer market was estimated to have acquired $129.8 billion in 2022. It is anticipated to register a 5.7% CAGR from 2023 to 2031 and by 2031, the market is likely to gain $211.8 billion.

According to research by Transparency Market Research Inc., there is a growing demand for high performance, lightweight engineering polymers for EV components, including battery casings, connectors, and thermal management systems, with the increasing shift towards electric vehicles.

Lightweight engineering polymers are crucial in the aerospace industry. There is an opportunity for these materials to be used in spacecraft and related applications, with a growing interest in space exploration.

Key players

The following companies are well known participants in the global engineering polymer market:

- BASF SE

- Asahi Kasei

- Celanese Corporation

- Covestro AG

- AKRO-PLASTIC GmbH

- Daicel Polymer Ltd.

- Kawasaki Sanko Kasei Co. Ltd.

Key findings

Engineering polymers are widely used in the automotive industry due to their lightweight and high performance properties. The demand for engineering polymers, is expected to rise, with the growing demand for fuel efficient and electric vehicles.

Additive manufacturing and 3D printing have been on the rise. Engineering polymers play a significant role in this field, and as 3D printing technology advances, there are increased

opportunities for these materials in various applications, including aerospace, healthcare, and automotive.

Emerging markets, particularly in Asia, have been witnessing rapid industrialization, which has led to increased demand for engineering polymers in various applications, including construction, electronics, and packaging.

Industries such as electronics, aerospace, and healthcare have a growing need for high performance polymers that offer exceptional properties like heat resistance, chemical resistance, and mechanical strength.

There is a need for engineering polymers that can meet the demands of miniaturization while maintaining performance and durability, as products in various industries become smaller and more compact.

The development of new manufacturing techniques and technologies for engineering polymers, as well as innovative formulations, can lead to the creation of advanced materials with improved properties, expanding the market.

Changes in regulations, particularly those related to safety and environmental standards, can impact the engineering polymer market. Companies that can adapt to these changes and develop compliant materials may have a competitive advantage.

The ability to offer customized engineering polymer solutions to meet specic industry needs and requirements is a growing trend. Companies that can provide tailored materials and formulations may nd increased opportunities.

Global market

Various reasons are propelling the growth of the engineering polymer market in different regions.

North America

North America has a significant automotive and transportation sector. The demand for lightweight and high performance engineering polymers in the automotive industry, including the production of electric vehicles, contributes to market growth.

The aerospace and defense industries in North America rely on engineering polymers for various applications, such as aircraft components and military equipment. The sectors provide a stable source of demand for high performance materials.

Asia Pacific

Asia Pacific is a global hub for electronics manufacturing. Engineering polymers are used in electronic components, connectors, and enclosures, with a high demand for materials that offer electrical insulating properties and flame resistance.

The packaging industry uses engineering polymers for food and beverage packaging, containers, films, and closures. The plastics industry relies on these materials for recycling and sustainability initiatives.