A Dormer Pramet pilot project for AI-based quality inspection has been successfully launched in the production unit in Šumperk, Czechia. The company said that the project has opened the door to achieving even higher quality in its Pramet inserts.

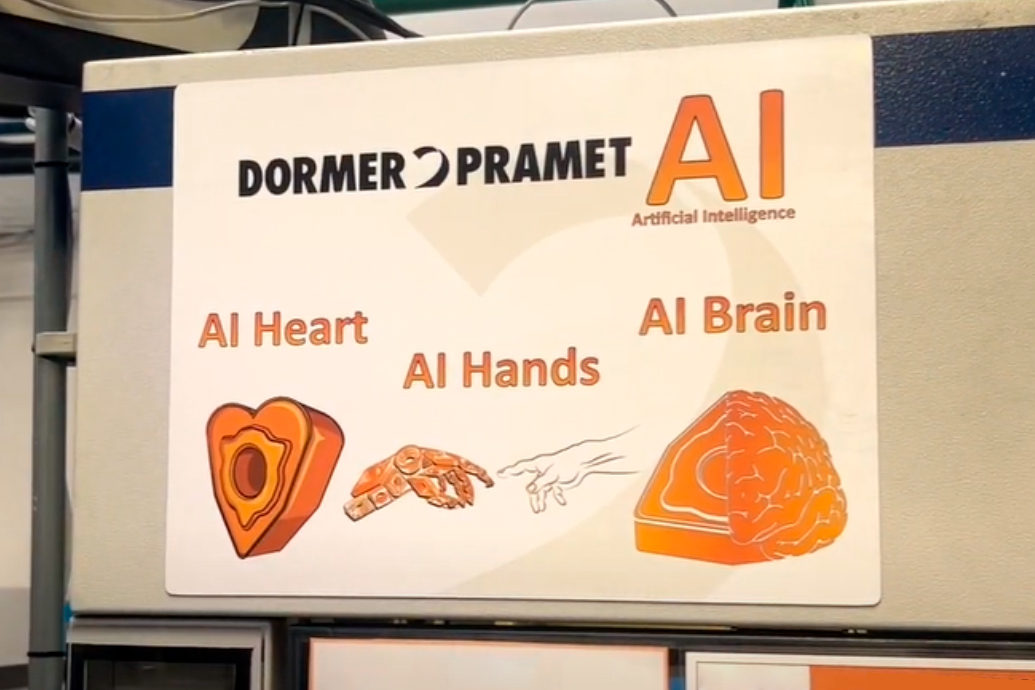

Dormer Pramet has started to look intensively into the possibility of using AI to manufacture tools. The global manufacturer’s first pilot project in this area is an autonomous inspection station at the pressing department in the production unit Šumperk. Located directly in the pressing machine, the new program can independently detect visual defects and evaluate non-conforming products during the pressing process.

The inspection station senses the pressed inserts using a system of cameras, lights, and moving mechanical elements. Automatic machine image recognition is performed over the images of inserts taken by the inspection station. A unique AI-based algorithm locates and identifies visual defects, and the machine operator can view the defect and react immediately to the situation. The goal is to prevent production of non-conforming pieces by catching any defects earlier.

The machine operator gives feedback to help the inspection station improve its skills for further decision-making.

Dormer Pramet is dedicated to delivering the highest possible quality tools that fulfil the promise of being Simply Reliable. The results of this project will lead the manufacturer to seek other possible uses for integrating AI into the production process.