Tipping point is defined as the time at which a series of small changes or incidents becomes significant enough to cause a larger, more important change. Whether the metal additive manufacturing, or 3-D printed, parts market is at that point depends on who you ask.

According to Terry Wohlers, head of advisory services and market intelligence at Wohlers Associates, the additive manufacturing (AM) industry is gaining traction in new ways, especially among manufacturers serving the space industry. (Wohlers Associates is now powered by ASTM International, which acquired the consulting firm in 2021.)

What could really impact the AM industry, Wohlers noted, is when the automotive industry embraces the technology in a much bigger way. Currently, cost is a major consideration. One example of adoption by the auto industry is the Cadillac Celestiq electric vehicle, which has 115 polymer and metal parts that are additively built.

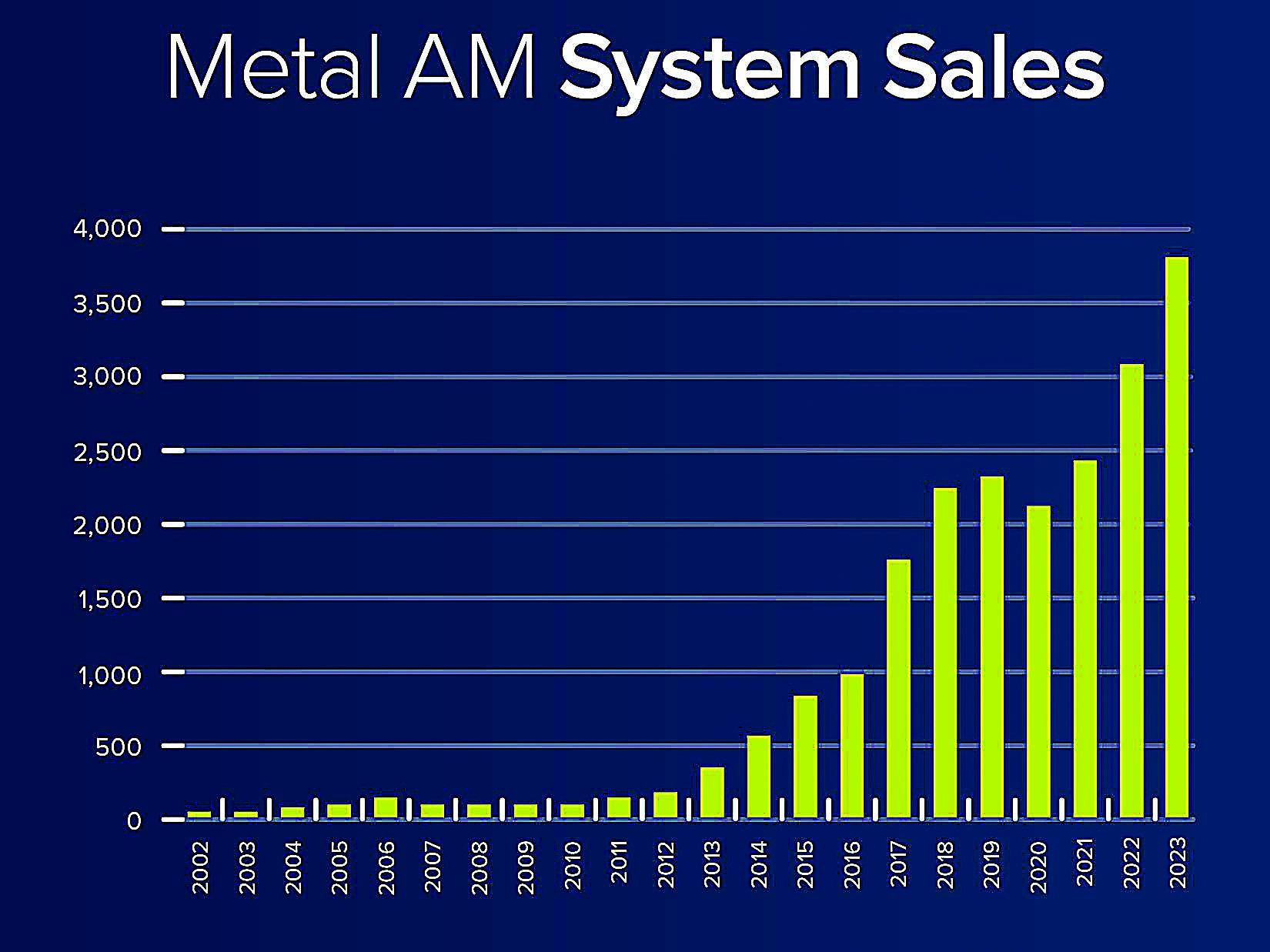

“Wohlers Report 2024,” the company’s annual report that tracks the AM industry, states that metal AM system sales increased by 24.4% in 2023, with an estimated 3,793 machines sold. The overall AM industry grew by 11.1% in 2023 compared to 18% in 2022.

Of the $3.65 billion worth of AM materials sold year last, Wohlers said 19.7% were metals. The most common metal AM process is powder bed fusion followed by directed energy deposition. “It’s still a distant second.”

The metal AM segment will see “incremental gains” moving forward, said Ted Sorom, co-founder and CEO of metal printing company Mantle Inc. in San Francisco. “To be honest, I don’t think we’ll see a true tipping point with metal additive.”

He added that when compared to how many metal parts are produced annually around the globe, the percentage made with metal additive is “infinitesimally small,” but manufacturers are finding applications for the technology that offer compelling benefits. “And that tipping point, that understanding of the match between the technologies available and what to do with them, that is happening right now in a way that we haven’t seen before.”

When the capabilities of metal AM are matched to a marketplace need, Sorom said the effect is significant. “We can deploy this technology not in an R&D setting, with a bunch of Ph.D.s poking at it, but in a production setting where it actually has a big impact on how we manufacture certain products, because for those products there are just massive wins.”

Not for Making S’Mores

Robert Bush said he will leave the task of pinpointing where the metal AM industry is at on the adoption curve to others. He is focused instead on the common goal of making AM an economic, repeatable, scalable and productive manufacturing process. He is CEO of Rivelin Robotics in Sheffield, U.K., which is the lead partner of a U.K.-funded project to deliver a digital postprocessing solution for the automated finishing of printed parts called Project CAMPFIRE (Certified Additive Manufactured Parts Finished with Intelligent Robotics Engine). Rivelin is collaborating with five partners.

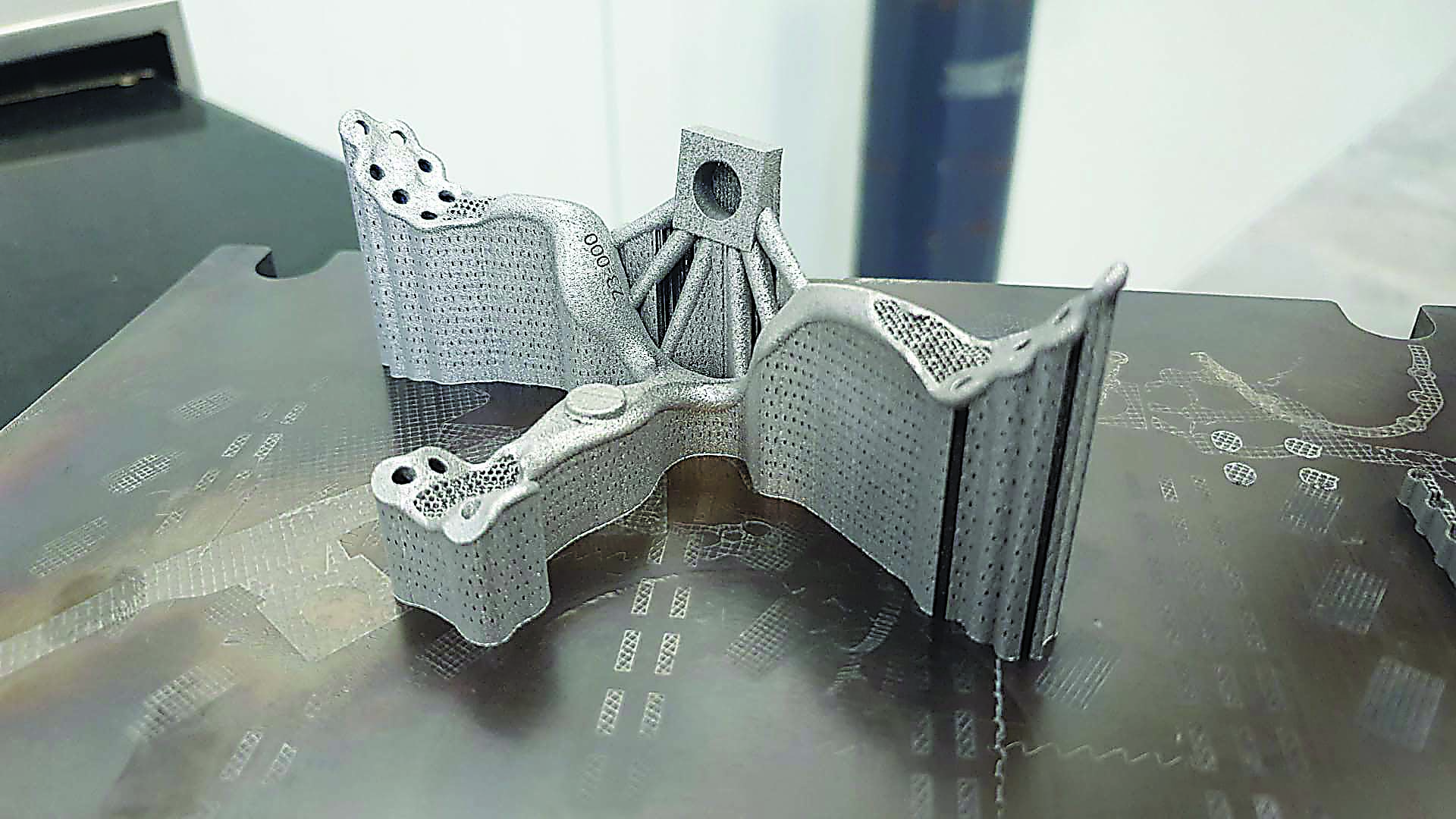

Postprocessing additive metal parts comes with many challenges — it’s labor-intensive, time-consuming, filthy and sometimes includes dangerous activities involved in removing metal supports with hand tools, Bush explained. The manual method is the most common because human workers have the needed dexterity, adaptability, flexibility and knowledge to make it the best option economically. “The people who do it are heroes. They are amazing. They are absolutely skilled.”

Nonetheless, a critical skills gap exists in the U.K., U.S. and other Western economies, Bush said, which became more pronounced after manufacturers based in the West moved production to low labor-cost countries and many later decided to reshore critical supply chains. In addition, manufacturers that can find skilled labor or train people, labor costs “have spiraled out of control” and safety and health regulations have become more stringent to better protect workers, which might not exist in lower-cost economies.

A solution is available, according to Bush. “You can be competitive with these lower-cost companies only if you harness automation.” Rivelin, for example, offers its Netshape robots to provide autonomous postprocessing capabilities. Rather than having humans wield sanders, angle grinders, grippers, hammers and other hand tools, a robot arm brandishes them instead, he said. With automation, part manufacturers can deploy existing workers to install and maintain the robots, and work on enhancing processes and continuous improvement, among others. “It can actually be adding more value and economic growth than just doing the same task over and over again.”

Like virtually every decision that arises when choosing the best way to manufacture something, switching from removing metal supports manually to robotically is ultimately a question of economics, Bush said. “It just depends on your return on investment timelines, your depreciation cycles and your needs around those. But if we can make it work in the most stringent industries, it can be made to work in any sector.”

A Mixed Approach

One AM technology that was making strides but has taken a backseat lately is hybrid AM in which a part is additively produced and machined in the same equipment. Wohlers noted that about a decade ago, the promise of hybrid systems has since waned. “We haven’t seen it as much and it’s a work in progress.”

He noted that it is possible for a family of parts to be dialed in and efficiently produced in a hybrid machine, but the same is not true with a wide range of parts, especially with intricate features. “It’s more difficult or impossible with hybrid systems to make them work well for certain types of parts.”

Also, distortion from high levels of heat from the metal additive process must be considered, Wohlers said. “It’s easier to do additive or machining than to combine both in one system.”

Bush concurred about the limitations of hybrid machining. “I’m not particularly enthused about that concept, although I completely see a place for it in industry.”

Generating adequate throughput is essential to eventually recovering the investment on a hybrid machine, which are usually expensive, he added. With a hybrid approach, throughput is being limited. “You’re creating a bottleneck because your printer is waiting while you machine your part in the same area. I just don’t think it will be a major player moving forward in manufacturing supply chains.”

Mantle developed a different method of hybrid machining with its sintering-based process, Sorom said. Using the company’s metal pastes, which include H-13 tool steel, 420 stainless steel and still-in-development D-2 tool steel, a part is printed and shaped in the P-200 printer and then transferred to the F-200 furnace for sintering. “After 10 layers of printing, we come in and machine away the layer lines you’d normally see and refine the part using traditional machining techniques.”

However, the machining is not performed when the part is metal, but rather when it is comprised of metal particles with some binder, Sorom explained, like cutting rigid foam. “We can cut that material 10 times faster than you could cut traditional true tool steels. Yes, other technologies are capable of both additive and subtractive in the same machine, but on the subtractive portion when the material is hardened, it is slow and laborious.”

Once sintered, Sorom said the resulting metal is as durable and performs the same as traditional metal. The company reports that both H-13 tool steel and 420 stainless steel have a hardness of more than 50 HRC after heat treatment. In one application, an H-13 plastic injection mold produced about 3.3 million parts over the last 2½ years.

He noted that about 90% of the applications for the machines and pastes are for mold inserts and tooling and the rest is for thread forming dies, die cast tooling, stamping dies and extrusion dies.

Legacy metal 3D-printed parts typically have a rough surface finish that require postprocessing of some or all the surfaces to meet

the tolerance specifications and achieve a suitable form and function, Sorom said. In addition, achieving flatness can require some work to eliminate waviness.

“All that postprocessing adds 25% to 30% more cost with legacy systems. Every other metal printer out there prints a near-net shape. After we print one of these inserts, there is little to no postprocessing,” he said, noting that the sintered parts can have a surface finish as fine as 1 µm to 3 µm Ra (0.00004" to 0.00012" Ra).

Besides reducing the cost per part, Mantle’s hybrid system reduces the capital equipment investment, according to Sorom. The P-200 printer costs $230,000 and the F-200 furnace costs $120,000, which combined he estimates is about a third of the price of other systems on the market. All Mantle customers have purchased both machines, and one furnace can serve multiple printers.

Nonetheless, he said Mantle has made the strategic decision not to chase all universal applications, but rather focus on just tooling, where the company’s system excels. For example, a frame for an aircraft seat might have a generative design for lightweighting, and other methods of metal printing would be a better choice. In contrast, Mantle’s system is ideal for making parts like H-13 injection mold inserts and dies, and 420 stainless tooling for medical devices. “We don’t do everything, but the things that we do, we do them extremely well.”

Business Case Justification

Wohlers emphasized that he rarely sees additive manufacturing as a replacement technology. Most of the time, it is used for new types of parts and products. Trying to replace a conventionally produced metal part for an automotive suspension system with an additive version, for instance, would be difficult to justify because of the high volume needed. However, benefits can be realized by redesigning a whole assembly, such as consolidating many parts into one.

Gains can also be realized by using AM to improve the performance of a part, reducing its weight or shortening the time it takes to go from concept to delivery to the customer, Wohlers added.

“Developing entirely new types of products is where the bigger opportunities lie,” he said. “Applying additive to production applications should be done on a case-by-case basis. You want to look at the job and ask if it is a good fit for additive. It may be, but it may not be and that’s the key in most cases.”

Related Glossary Terms

- 3-D

3-D

Way of displaying real-world objects in a natural way by showing depth, height and width. This system uses the X, Y and Z axes.

- extrusion

extrusion

Conversion of an ingot or billet into lengths of uniform cross section by forcing metal to flow plastically through a die orifice.

- family of parts

family of parts

Parts grouped by shape and size for efficient manufacturing.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- lapping compound( powder)

lapping compound( powder)

Light, abrasive material used for finishing a surface.

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.

- sintering

sintering

Bonding of adjacent surfaces in a mass of particles by molecular or atomic attraction on heating at high temperatures below the melting temperature of any constituent in the material. Sintering strengthens and increases the density of a powder mass and recrystallizes powder metals.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- tool steels

tool steels

Group of alloy steels which, after proper heat treatment, provide the combination of properties required for cutting tool and die applications. The American Iron and Steel Institute divides tool steels into six major categories: water hardening, shock resisting, cold work, hot work, special purpose and high speed.

- waviness

waviness

The more widely spaced component of the surface texture. Includes all irregularities spaced more widely than the instrument cutoff setting. See flows; lay; roughness.

Contributors

Mantle Inc.

415-655-3555

www.mantle3d.com

Rivelin Robotics

+44 114 700 3984

www.rivelinrobotics.com

Wohlers Associates, powered by ASTM International

970-225-0086

www.wohlersassociates.com