Canon U.S.A.., a leader in digital imaging solutions, developed a bagging system with its customer OSARO Inc., a San Francisco-based Canon U.S.A. customer that provides sophisticated AI-based robotic perception and picking solutions.

The OSARO Robotic Bagging System uses Canon’s optical-encoder-based, durable, and low-cost force-torque sensor. The system was showcased in September at the International Manufacturing Technology Show (IMTS) in Chicago.

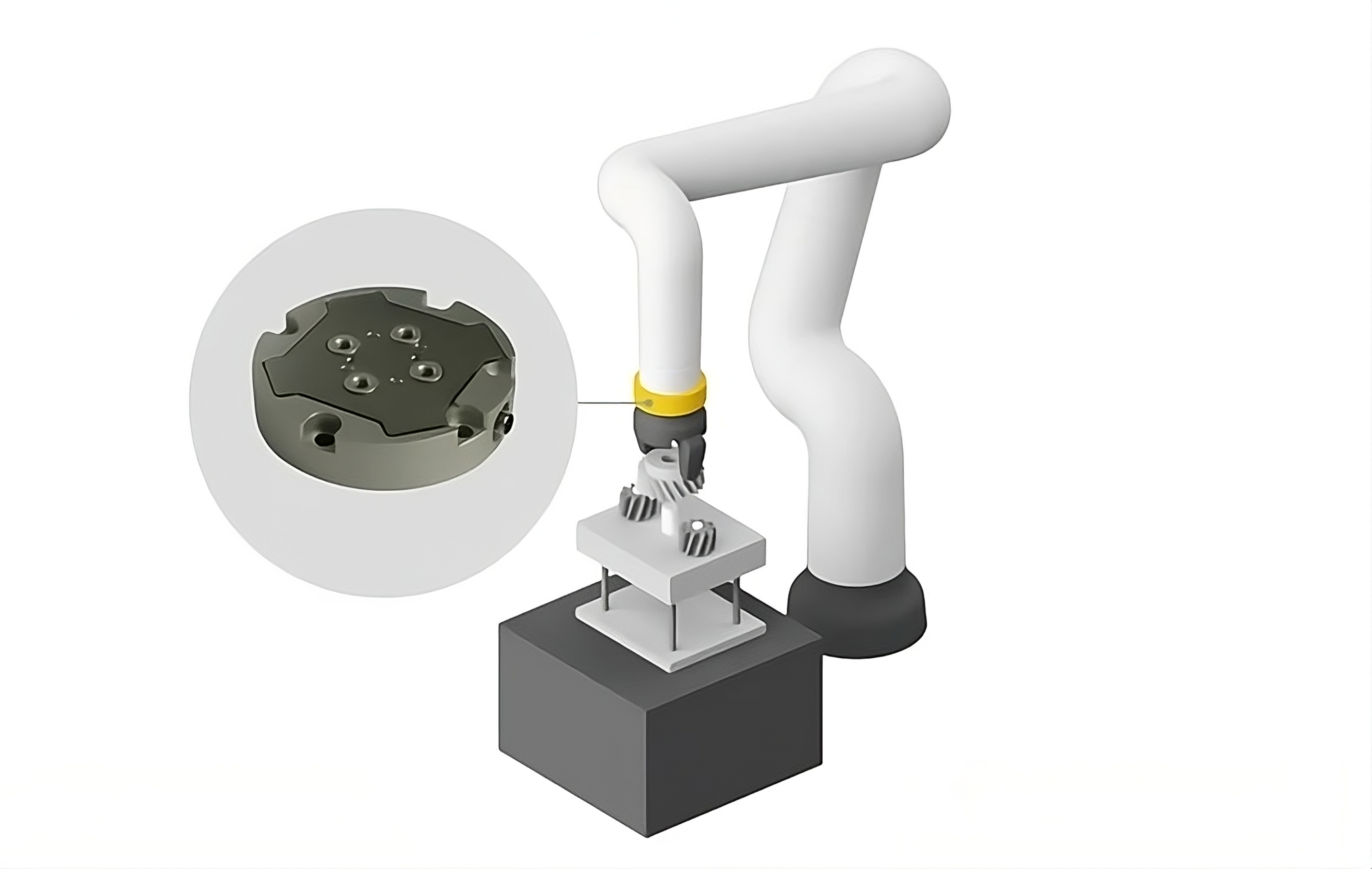

Attendees also saw Canon's industrial measurement technology including a durable force-torque sensor. The sensor can measure the magnitude and direction of load along three axes and rotational forces. When attached to a robotic arm, a force sensor helps the arm sense the strength needed to handle objects.

Canon’s force sensors, featuring a simple structure due to advanced optical encoders, are durable, thin, lightweight, and highly precise, with the added benefit of being fully digital to proffer a low-noise effect. It can be installed on robotic arms for various tasks, aiding with automation for areas still reliant on manual work, while being less prone to damage compared to older analog methods due to it being a non-contact structure.

“We are pleased to share some of the latest innovations from Canon and OSARO with professionals at the International Manufacturing Technology Show in Chicago,” said Kenichi Kaneda, Senior Director and GM, Industrial Products Division. “Durability, low-cost and precision are critical to providing the best options for their application, and we are pleased that Canon was able to provide a much-needed product.”

The force torque sensor, measuring just three-quarters of an inch (in thickness) and weighing .55 pounds, contains Canon’s proprietary optical encoder technology. A digital mechanism works to provide high precision levels, and the Canon Force Torque Sensor Application Software can allow users to connect their sensor to a personal computer without any need for coding while testing.

OSARO’s Robotic Bagging System aims to transform order fulfillment by automating SKU bagging with advanced pick-and-place software that integrates with leading packaging equipment. This system can reduce overhead and mitigate labor shortages while meeting the customer’s throughput requirements. Powered by OSARO’s advanced AI and machine-learning algorithms, OSARO SightWorks delivers unparalleled flexibility by enabling the automatic addition of thousands of new SKUs without downtime. With dynamic object detection and the ability to adapt to changing inventory in real time, SightWorks ensures accurate, efficient, and versatile order processing, even in the face of evolving warehouse environments.

“OSARO is pleased to work with Canon to showcase our robotic bagging solution at IMTS,” said Brent Barcey, SVP of corporate development at OSARO. “Canon’s advanced sensors provide a compelling combination of value, performance, and quality, which, combined with OSARO's self-learning perception intelligence, can help drive continued growth with e-commerce and fulfillment customers around the world."

Related Glossary Terms

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).