Products

•

December 30, 2020

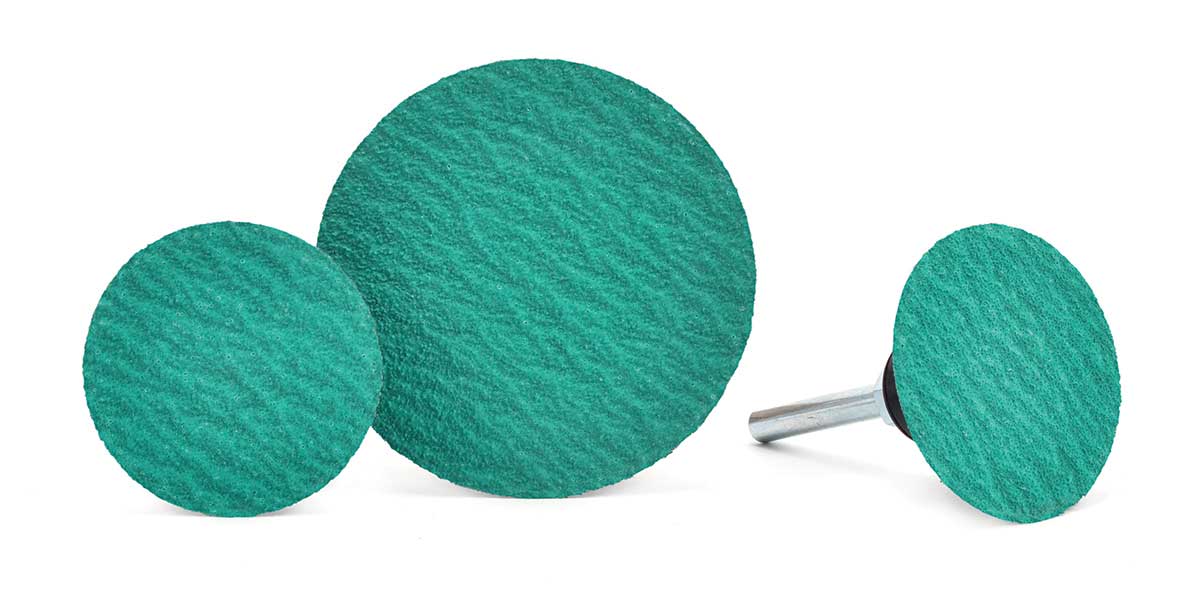

SHUR-KUT Zirconia Grinding Aid Quick Change Discs

With a smaller diameter, quick change discs provide ease of use on intricate parts and excellent control when shaping or blending surface portions, especially on flat surfaces. Moderate flexibility of quick change discs and their holders allows contouring and access to inner corners. These unique quick change functionality reduces changeover downtime and eases transitions between grit, material, or even abrasive type where multi-step processes are required.