Products

•

September 7, 2024

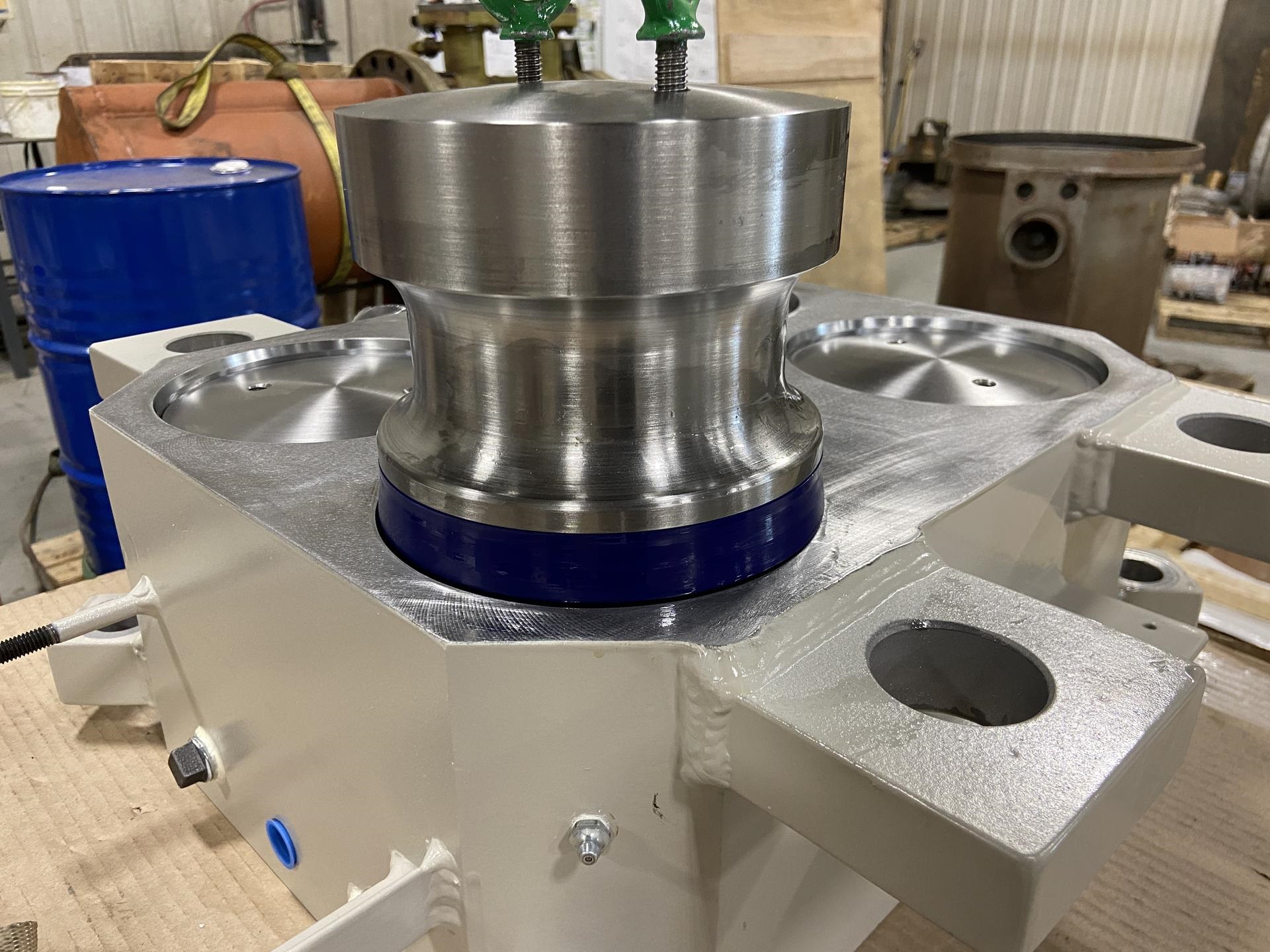

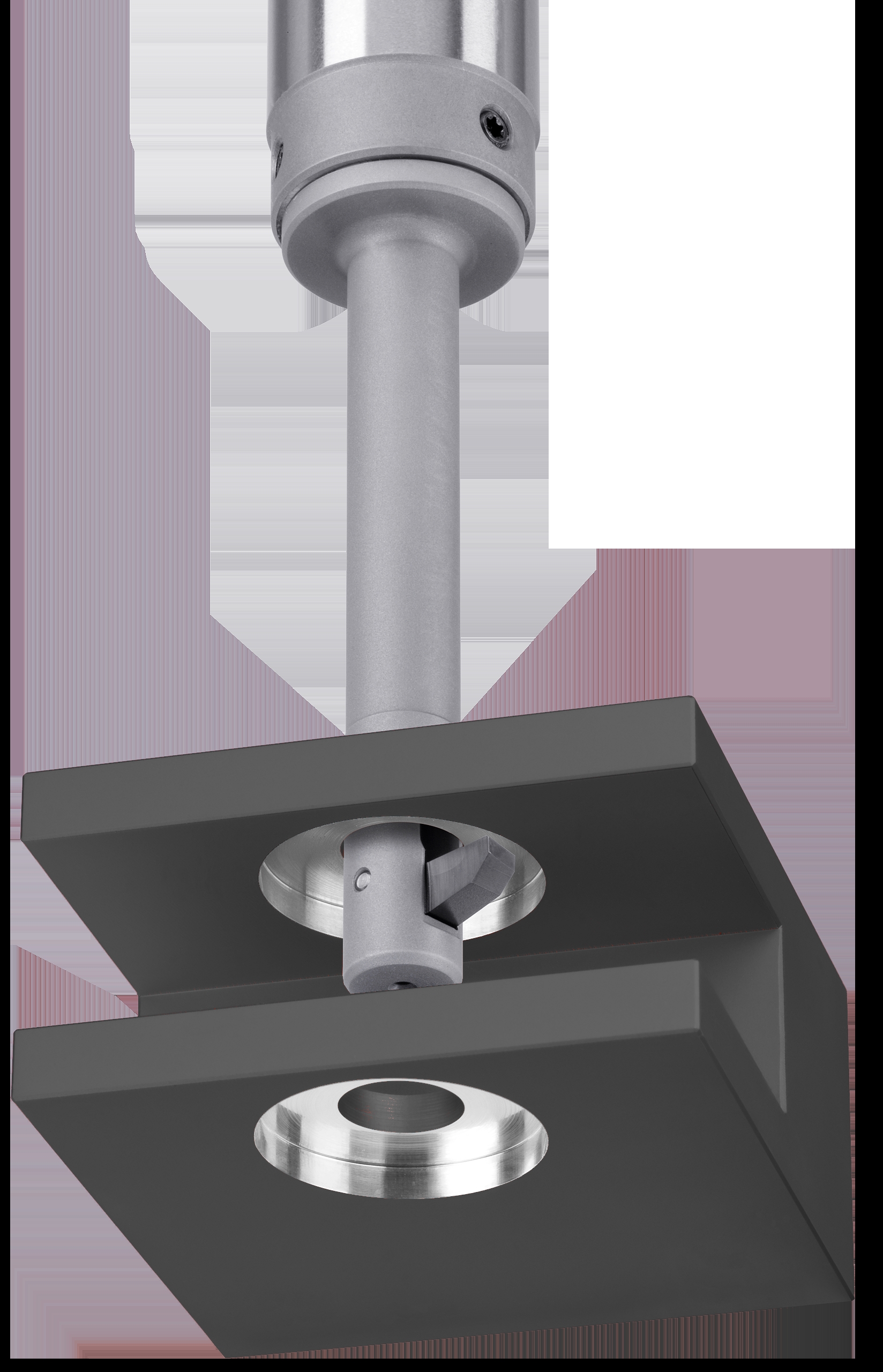

TRU TECH T93XM Perimetric Grinder

The T93XM can profile with a standard 1A1 wheel and accommodates several grind styles including wheel profile, plunge, peel, in-feed and thru-feed grinding. The perimetric workholding, unique to TRU TECH, ensures part concentricity to eliminate shank runout without indicating. Ultra-precision accuracy is achieved through the 3-axis, fully programmable configuration with CNC variable speed spindle. Pick-N-Place™ software eases and shortens programming setup time. Several design features add stability and further support operator ergonomic considerations. Part sizes can be 3" (75mm) in diameter, up to 8" (200mm) in length.